正在加载图片...

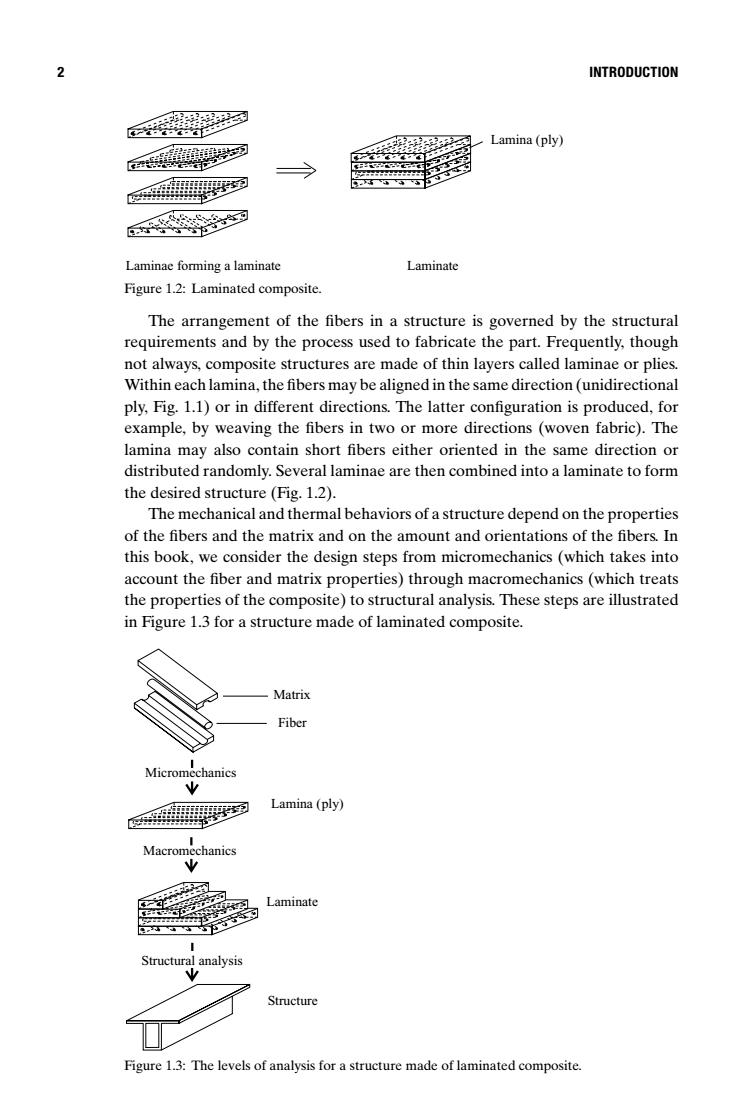

2 INTRODUCTION Lamina(ply) 习 Laminae forming a laminate Laminate Figure 1.2:Laminated composite. The arrangement of the fibers in a structure is governed by the structural requirements and by the process used to fabricate the part.Frequently,though not always,composite structures are made of thin layers called laminae or plies. Within each lamina,the fibers may be aligned in the same direction(unidirectional ply,Fig.1.1)or in different directions.The latter configuration is produced,for example,by weaving the fibers in two or more directions (woven fabric).The lamina may also contain short fibers either oriented in the same direction or distributed randomly.Several laminae are then combined into a laminate to form the desired structure (Fig.1.2). The mechanical and thermal behaviors of a structure depend on the properties of the fibers and the matrix and on the amount and orientations of the fibers.In this book,we consider the design steps from micromechanics(which takes into account the fiber and matrix properties)through macromechanics(which treats the properties of the composite)to structural analysis.These steps are illustrated in Figure 1.3 for a structure made of laminated composite. Matrix Fiber Micromechanics 么 Lamina(ply) Macromechanics V 的 Laminate Structural analysis 业 Structure Figure 1.3:The levels of analysis for a structure made of laminated composite.2 INTRODUCTION Laminae forming a laminate Laminate Lamina (ply) Figure 1.2: Laminated composite. The arrangement of the fibers in a structure is governed by the structural requirements and by the process used to fabricate the part. Frequently, though not always, composite structures are made of thin layers called laminae or plies. Within each lamina, the fibers may be aligned in the same direction (unidirectional ply, Fig. 1.1) or in different directions. The latter configuration is produced, for example, by weaving the fibers in two or more directions (woven fabric). The lamina may also contain short fibers either oriented in the same direction or distributed randomly. Several laminae are then combined into a laminate to form the desired structure (Fig. 1.2). The mechanical and thermal behaviors of a structure depend on the properties of the fibers and the matrix and on the amount and orientations of the fibers. In this book, we consider the design steps from micromechanics (which takes into account the fiber and matrix properties) through macromechanics (which treats the properties of the composite) to structural analysis. These steps are illustrated in Figure 1.3 for a structure made of laminated composite. Matrix Fiber Micromechanics Macromechanics Laminate Structural analysis Structure Lamina (ply) Figure 1.3: The levels of analysis for a structure made of laminated composite