正在加载图片...

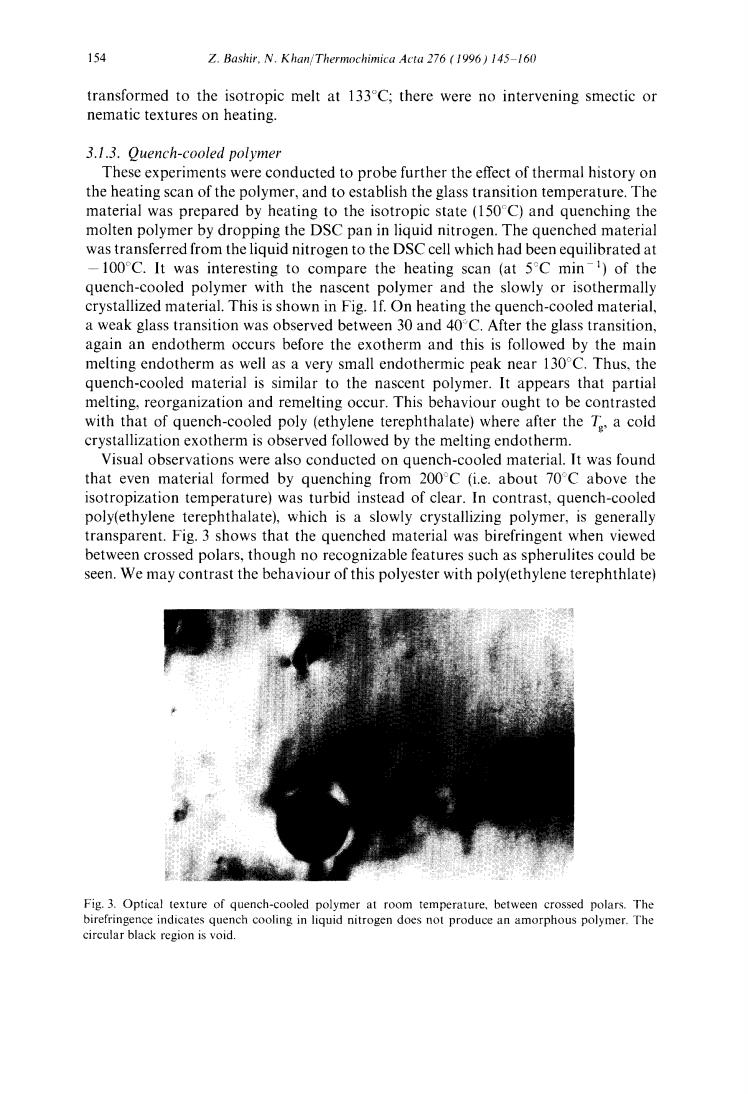

154 Z Bashir N Khan Thermachimica Acta 276(1996)145-160 transformed to the isotropic melt at 133C;there were no intervening smectic or nematic textures on heating 3.1.3.Quench-cooled polymer erim the heating scar of the n material olymer.an h as prepar ed by hea the e glass transi state (150C)and ching th opping the DS he DSCcll which had I he quench materia 00C.It was interesting to compare the heating scan (at 5Cmin of the -cooled polyme with the nascent polymer and the slowly or isothermally crystallized material.This is shown in Fig.If.On heating the quench-cooled material. a weak glass transition was observed between 30 and 40C.After the glass transition, again an endotherm occurs before the exotherm and this is followed by the main melting endotherm as well as a very small endothermic peak near 130C.Thus.the quench-cooled material is similar to the nascent polymer.It appears that partial melting.reorganization and remelting occur.This behaviour ought to be contrasted with that of quench-cooled poly (ethylene terephthalate)where after the T a cold crystallization exotherm is observed followed by the melting endotherm Visual observations were also conducted on quench-cooled material.It was found that even material formed by quenching from 200C (i.e.about 70C above the isotropization temperature)was turbid instead of clear.In contrast,quench-c poly(ethylene terephthalate).which is a slowly ge nsparent Fig.shows that thequn ched ms t whe able s spher een. We may contrast the behaviour of this polyester with poly(ethylene terephthlate texture of quench-cooled polymer at room temperature.between erossed polars The 154 Z. Bashir, N. K han/Thermochimica Acta 276 (1996) 145 160 transformed to the isotropic melt at 133°C; there were no intervening smectic or nematic textures on heating. 3.1.3. Quench-cooled polymer These experiments were conducted to probe further the effect of thermal history on the heating scan of the polymer, and to establish the glass transition temperature. The material was prepared by heating to the isotropic state (150'C) and quenching the molten polymer by dropping the DSC pan in liquid nitrogen. The quenched material was transferred from the liquid nitrogen to the DSC cell which had been equilibrated at -100c'C. It was interesting to compare the heating scan (at 5°C rain 1) of the quench-cooled polymer with the nascent polymer and the slowly or isothermally crystallized material. This is shown in Fig. lf. On heating the quench-cooled material, a weak glass transition was observed between 30 and 40:~C. After the glass transition, again an endotherm occurs before the exotherm and this is followed by the main melting endotherm as well as a very small endothermic peak near 130"~C. Thus, the quench-cooled material is similar to the nascent polymer. It appears that partial melting, reorganization and remelting occur. This behaviour ought to be contrasted with that of quench-cooled poly (ethylene terephthalate) where after the Tg, a cold crystallization exotherm is observed followed by the melting endotherm. Visual observations were also conducted on quench-cooled material. It was found that even material formed by quenching from 200C (i.e. about 70~C above the isotropization temperature) was turbid instead of clear. In contrast, quench-cooled poly(ethylene terephthalate), which is a slowly crystallizing polymer, is generally transparent. Fig. 3 shows that the quenched material was birefringent when viewed between crossed polars, though no recognizable features such as spherulites could be seen. We may contrast the behaviour of this polyester with poly(ethylene terephthlate) Fig. 3. Optical texture of quench-cooled polymer at room temperature, between crossed polars. The birefringence indicates quench cooling in liquid nitrogen does not produce an amorphous polymer. The circular black region is void