正在加载图片...

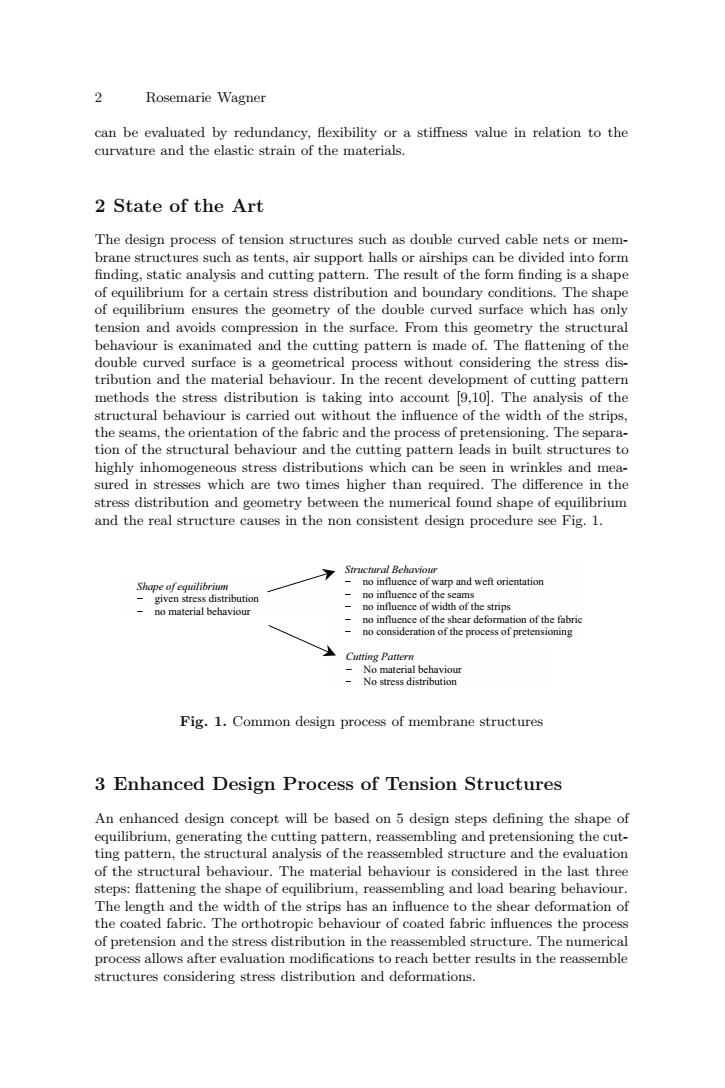

2 Rosemarie Wagner can be evaluated by redundancy,flexibility or a stiffness value in relation to the curvature and the elastic strain of the materials. 2 State of the Art The design process of tension structures such as double curved cable nets or mem- brane structures such as tents,air support halls or airships can be divided into form finding,static analysis and cutting pattern.The result of the form finding is a shape of equilibrium for a certain stress distribution and boundary conditions.The shape of equilibrium ensures the geometry of the double curved surface which has only tension and avoids compression in the surface.From this geometry the structural behaviour is exanimated and the cutting pattern is made of.The flattening of the double curved surface is a geometrical process without considering the stress dis- tribution and the material behaviour.In the recent development of cutting pattern methods the stress distribution is taking into account 9,10.The analysis of the structural behaviour is carried out without the influence of the width of the strips, the seams,the orientation of the fabric and the process of pretensioning.The separa- tion of the structural behaviour and the cutting pattern leads in built structures to highly inhomogeneous stress distributions which can be seen in wrinkles and mea- sured in stresses which are two times higher than required.The difference in the stress distribution and geometry between the numerical found shape of equilibrium and the real structure causes in the non consistent design procedure see Fig.1. Structural Behaviour Shape ofequilibrium no influence of warp and weft orientation given stress distribution no influence of the seams no material behaviour no influence of width of the strips no influence of the shear deformation of the fabric no consideration of the process of pretensioning Cutting Pattern No material behaviour No stress distribution Fig.1.Common design process of membrane structures 3 Enhanced Design Process of Tension Structures An enhanced design concept will be based on 5 design steps defining the shape of equilibrium,generating the cutting pattern,reassembling and pretensioning the cut- ting pattern,the structural analysis of the reassembled structure and the evaluation of the structural behaviour.The material behaviour is considered in the last three steps:flattening the shape of equilibrium,reassembling and load bearing behaviour. The length and the width of the strips has an influence to the shear deformation of the coated fabric.The orthotropic behaviour of coated fabric influences the process of pretension and the stress distribution in the reassembled structure.The numerical process allows after evaluation modifications to reach better results in the reassemble structures considering stress distribution and deformations.2 Rosemarie Wagner can be evaluated by redundancy, flexibility or a stiffness value in relation to the curvature and the elastic strain of the materials. 2 State of the Art The design process of tension structures such as double curved cable nets or membrane structures such as tents, air support halls or airships can be divided into form finding, static analysis and cutting pattern. The result of the form finding is a shape of equilibrium for a certain stress distribution and boundary conditions. The shape of equilibrium ensures the geometry of the double curved surface which has only tension and avoids compression in the surface. From this geometry the structural behaviour is exanimated and the cutting pattern is made of. The flattening of the double curved surface is a geometrical process without considering the stress distribution and the material behaviour. In the recent development of cutting pattern methods the stress distribution is taking into account [9,10]. The analysis of the structural behaviour is carried out without the influence of the width of the strips, the seams, the orientation of the fabric and the process of pretensioning. The separation of the structural behaviour and the cutting pattern leads in built structures to highly inhomogeneous stress distributions which can be seen in wrinkles and measured in stresses which are two times higher than required. The difference in the stress distribution and geometry between the numerical found shape of equilibrium and the real structure causes in the non consistent design procedure see Fig. 1. Fig. 1. Common design process of membrane structures 3 Enhanced Design Process of Tension Structures An enhanced design concept will be based on 5 design steps defining the shape of equilibrium, generating the cutting pattern, reassembling and pretensioning the cutting pattern, the structural analysis of the reassembled structure and the evaluation of the structural behaviour. The material behaviour is considered in the last three steps: flattening the shape of equilibrium, reassembling and load bearing behaviour. The length and the width of the strips has an influence to the shear deformation of the coated fabric. The orthotropic behaviour of coated fabric influences the process of pretension and the stress distribution in the reassembled structure. The numerical process allows after evaluation modifications to reach better results in the reassemble structures considering stress distribution and deformations. Shape of equilibrium í given stress distribution í no material behaviour Structural Behaviour í no influence of warp and weft orientation í no influence of the seams í no influence of width of the strips í no influence of the shear deformation of the fabric í no consideration of the process of pretensioning Cutting Pattern í No material behaviour í No stress distribution