正在加载图片...

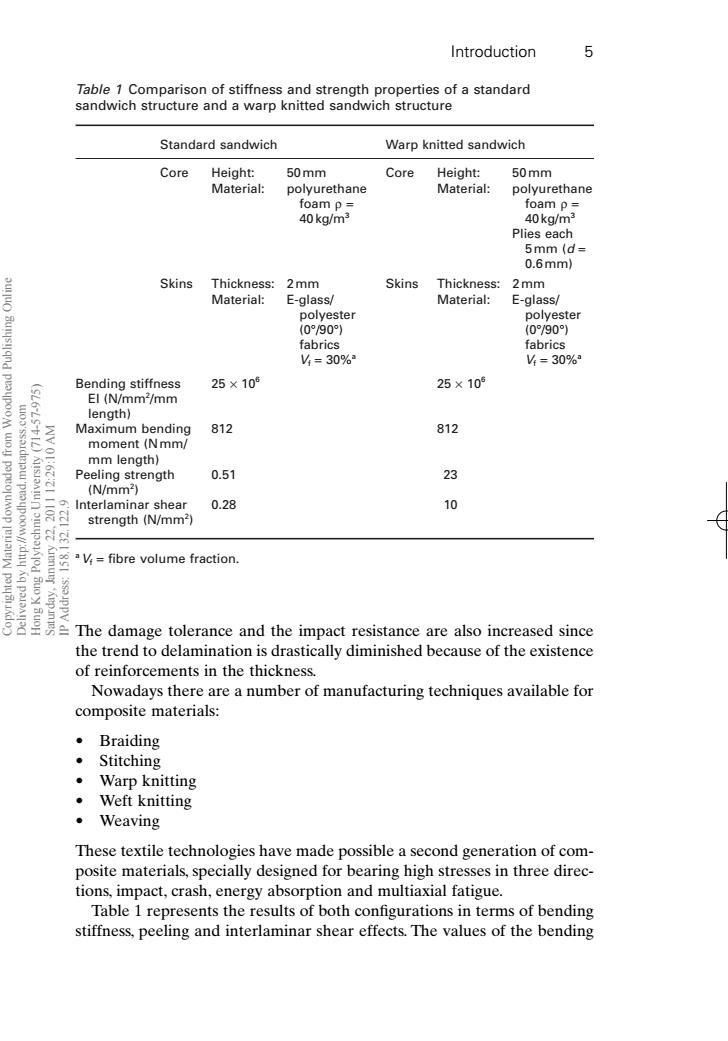

Introduction 5 Table 1 Comparison of stiffness and strength properties of a standard sandwich structure and a warp knitted sandwich structure Standard sandwich Warp knitted sandwich Core Height: 50mm Core Height: 50mm Material: polyurethane Material: polyurethane foam p= foam p= 40 kg/m3 40kg/m3 Plies each 5mm (d= 0.6mm) Skins Thickness:2mm Skins Thickness:2mm Material: E-glass/ Material: E-glass/ polyester polyester (0°/190) (0/90) fabrics fabrics V=30% 4=30% Bending stiffness 25×10 25×10 poo El(N/mm7/mm length) Maximum bending 812 812 10:6 moment(Nmm/ mm length) Peeling strength 0.51 23 (N/mm2) Interlaminar shear 0.28 10 strength (N/mm2) 号 V=fibre volume fraction. The damage tolerance and the impact resistance are also increased since the trend to delamination is drastically diminished because of the existence of reinforcements in the thickness. Nowadays there are a number of manufacturing techniques available for composite materials: 。Braiding ·Stitching Warp knitting Weft knitting Weaving These textile technologies have made possible a second generation of com- posite materials,specially designed for bearing high stresses in three direc- tions,impact,crash,energy absorption and multiaxial fatigue. Table 1 represents the results of both configurations in terms of bending stiffness,peeling and interlaminar shear effects.The values of the bendingThe damage tolerance and the impact resistance are also increased since the trend to delamination is drastically diminished because of the existence of reinforcements in the thickness. Nowadays there are a number of manufacturing techniques available for composite materials: • Braiding • Stitching • Warp knitting • Weft knitting • Weaving These textile technologies have made possible a second generation of composite materials, specially designed for bearing high stresses in three directions, impact, crash, energy absorption and multiaxial fatigue. Table 1 represents the results of both configurations in terms of bending stiffness, peeling and interlaminar shear effects. The values of the bending Introduction 5 Table 1 Comparison of stiffness and strength properties of a standard sandwich structure and a warp knitted sandwich structure Standard sandwich Warp knitted sandwich Core Height: 50mm Core Height: 50mm Material: polyurethane Material: polyurethane foam r = foam r = 40kg/m3 40kg/m3 Plies each 5mm (d = 0.6mm) Skins Thickness: 2mm Skins Thickness: 2mm Material: E-glass/ Material: E-glass/ polyester polyester (0°/90°) (0°/90°) fabrics fabrics Vf = 30%a Vf = 30%a Bending stiffness 25 ¥ 106 25 ¥ 106 EI (N/mm2 /mm length) Maximum bending 812 812 moment (Nmm/ mm length) Peeling strength 0.51 23 (N/mm2 ) Interlaminar shear 0.28 10 strength (N/mm2 ) aVf = fibre volume fraction. RICIN 7/10/99 7:11 PM Page 5 Copyrighted Material downloaded from Woodhead Publishing Online Delivered by http://woodhead.metapress.com Hong Kong Polytechnic University (714-57-975) Saturday, January 22, 2011 12:29:10 AM IP Address: 158.132.122.9