正在加载图片...

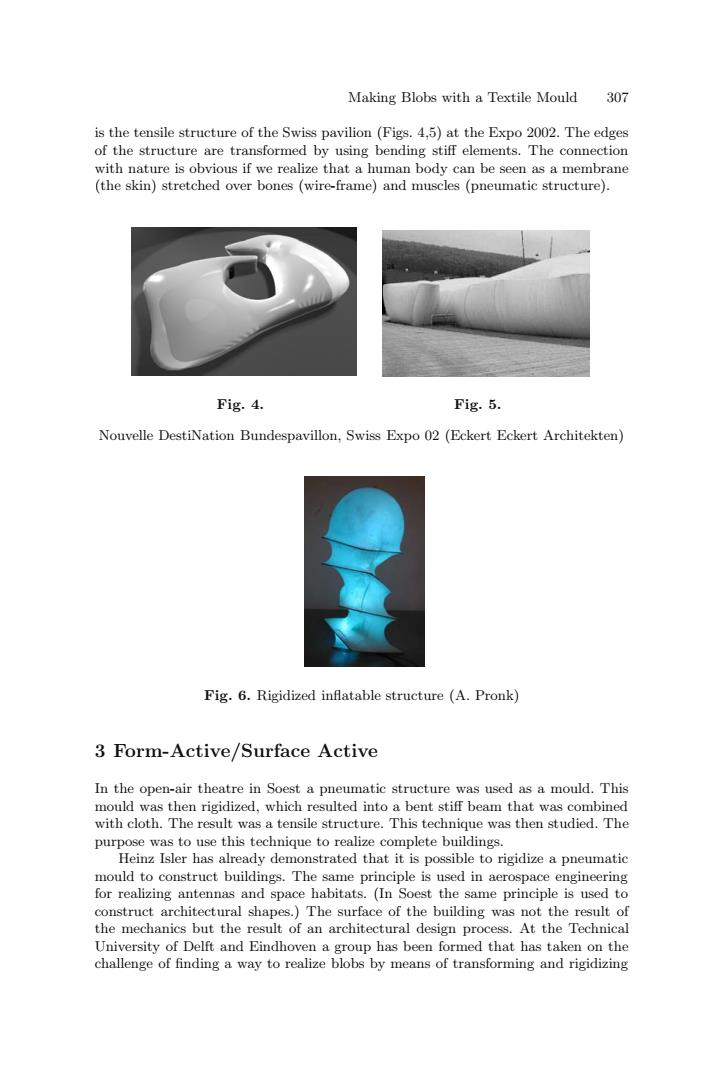

Making Blobs with a Textile Mould 307 is the tensile structure of the Swiss pavilion(Figs.4,5)at the Expo 2002.The edges of the structure are transformed by using bending stiff elements.The connection with nature is obvious if we realize that a human body can be seen as a membrane (the skin)stretched over bones (wire-frame)and muscles (pneumatic structure). Fig.4. Fig.5. Nouvelle DestiNation Bundespavillon,Swiss Expo 02(Eckert Eckert Architekten) Fig.6.Rigidized inflatable structure (A.Pronk) 3 Form-Active/Surface Active In the open-air theatre in Soest a pneumatic structure was used as a mould.This mould was then rigidized,which resulted into a bent stiff beam that was combined with cloth.The result was a tensile structure.This technique was then studied.The purpose was to use this technique to realize complete buildings. Heinz Isler has already demonstrated that it is possible to rigidize a pneumatic mould to construct buildings.The same principle is used in aerospace engineering for realizing antennas and space habitats.(In Soest the same principle is used to construct architectural shapes.)The surface of the building was not the result of the mechanics but the result of an architectural design process.At the Technical University of Delft and Eindhoven a group has been formed that has taken on the challenge of finding a way to realize blobs by means of transforming and rigidizingMaking Blobs with a Textile Mould 307 is the tensile structure of the Swiss pavilion (Figs. 4,5) at the Expo 2002. The edges of the structure are transformed by using bending stiff elements. The connection with nature is obvious if we realize that a human body can be seen as a membrane (the skin) stretched over bones (wire-frame) and muscles (pneumatic structure). Fig. 4. Fig. 5. Nouvelle DestiNation Bundespavillon, Swiss Expo 02 (Eckert Eckert Architekten) Fig. 6. Rigidized inflatable structure (A. Pronk) 3 Form-Active/Surface Active In the open-air theatre in Soest a pneumatic structure was used as a mould. This mould was then rigidized, which resulted into a bent stiff beam that was combined with cloth. The result was a tensile structure. This technique was then studied. The purpose was to use this technique to realize complete buildings. Heinz Isler has already demonstrated that it is possible to rigidize a pneumatic mould to construct buildings. The same principle is used in aerospace engineering for realizing antennas and space habitats. (In Soest the same principle is used to construct architectural shapes.) The surface of the building was not the result of the mechanics but the result of an architectural design process. At the Technical University of Delft and Eindhoven a group has been formed that has taken on the challenge of finding a way to realize blobs by means of transforming and rigidizing