正在加载图片...

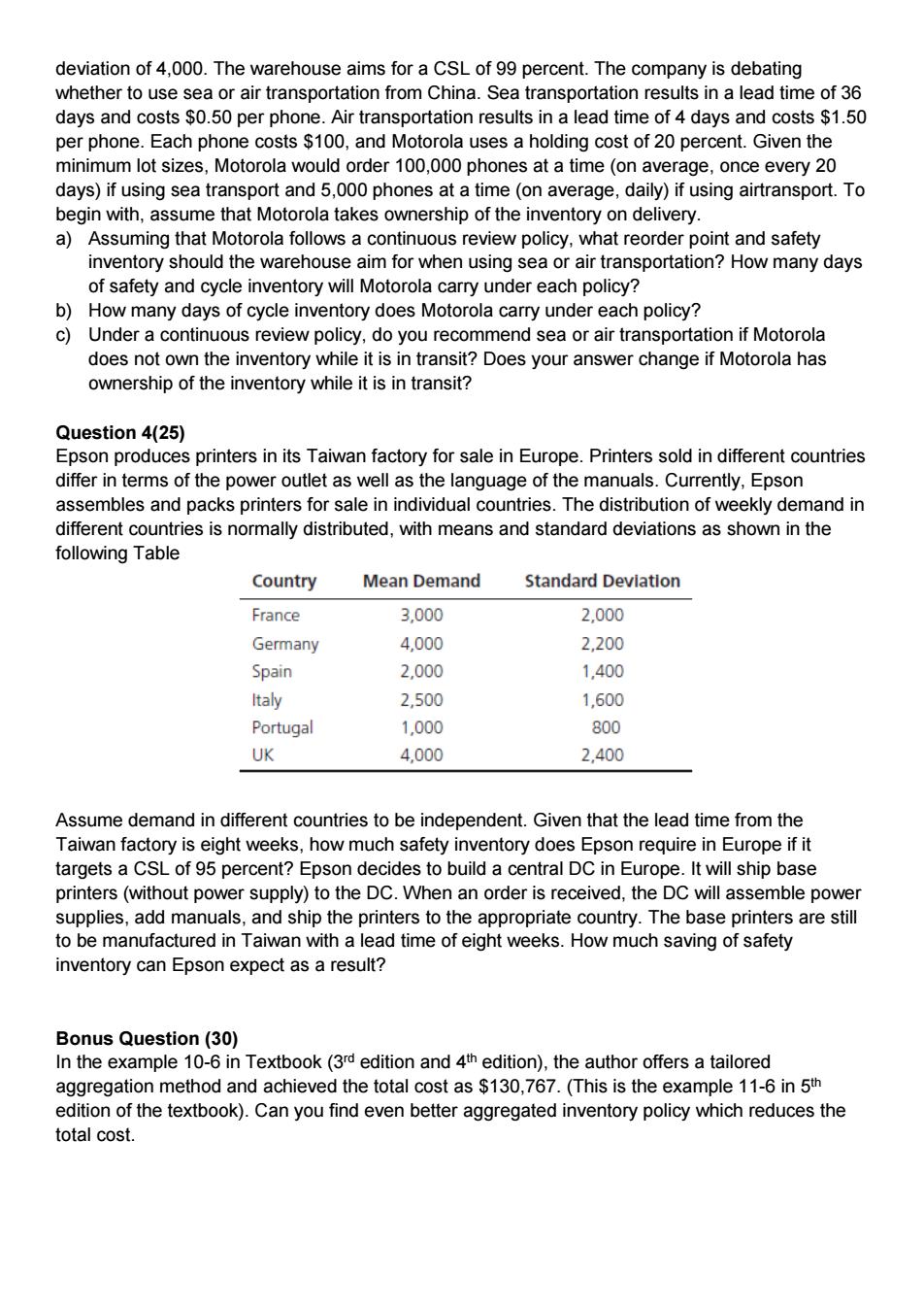

deviation of 4,000.The warehouse aims for a CSL of 99 percent.The company is debating whether to use sea or air transportation from China.Sea transportation results in a lead time of 36 days and costs $0.50 per phone.Air transportation results in a lead time of 4 days and costs $1.50 per phone.Each phone costs $100,and Motorola uses a holding cost of 20 percent.Given the minimum lot sizes,Motorola would order 100,000 phones at a time (on average,once every 20 days)if using sea transport and 5,000 phones at a time(on average,daily)if using airtransport.To begin with,assume that Motorola takes ownership of the inventory on delivery. a)Assuming that Motorola follows a continuous review policy,what reorder point and safety inventory should the warehouse aim for when using sea or air transportation?How many days of safety and cycle inventory will Motorola carry under each policy? b)How many days of cycle inventory does Motorola carry under each policy? c)Under a continuous review policy,do you recommend sea or air transportation if Motorola does not own the inventory while it is in transit?Does your answer change if Motorola has ownership of the inventory while it is in transit? Question 4(25) Epson produces printers in its Taiwan factory for sale in Europe.Printers sold in different countries differ in terms of the power outlet as well as the language of the manuals.Currently,Epson assembles and packs printers for sale in individual countries.The distribution of weekly demand in different countries is normally distributed,with means and standard deviations as shown in the following Table Country Mean Demand Standard Devlation France 3.000 2,000 Germany 4.000 2.200 Spain 2.000 1.400 Italy 2,500 1,600 Portugal 1.000 800 UK 4,000 2.400 Assume demand in different countries to be independent.Given that the lead time from the Taiwan factory is eight weeks,how much safety inventory does Epson require in Europe if it targets a CSL of 95 percent?Epson decides to build a central DC in Europe.It will ship base printers(without power supply)to the DC.When an order is received,the DC will assemble power supplies,add manuals,and ship the printers to the appropriate country.The base printers are still to be manufactured in Taiwan with a lead time of eight weeks.How much saving of safety inventory can Epson expect as a result? Bonus Question(30) In the example 10-6 in Textbook(3rd edition and 4th edition),the author offers a tailored aggregation method and achieved the total cost as $130,767.(This is the example 11-6 in 5th edition of the textbook).Can you find even better aggregated inventory policy which reduces the total cost.deviation of 4,000. The warehouse aims for a CSL of 99 percent. The company is debating whether to use sea or air transportation from China. Sea transportation results in a lead time of 36 days and costs $0.50 per phone. Air transportation results in a lead time of 4 days and costs $1.50 per phone. Each phone costs $100, and Motorola uses a holding cost of 20 percent. Given the minimum lot sizes, Motorola would order 100,000 phones at a time (on average, once every 20 days) if using sea transport and 5,000 phones at a time (on average, daily) if using airtransport. To begin with, assume that Motorola takes ownership of the inventory on delivery. a) Assuming that Motorola follows a continuous review policy, what reorder point and safety inventory should the warehouse aim for when using sea or air transportation? How many days of safety and cycle inventory will Motorola carry under each policy? b) How many days of cycle inventory does Motorola carry under each policy? c) Under a continuous review policy, do you recommend sea or air transportation if Motorola does not own the inventory while it is in transit? Does your answer change if Motorola has ownership of the inventory while it is in transit? Question 4(25) Epson produces printers in its Taiwan factory for sale in Europe. Printers sold in different countries differ in terms of the power outlet as well as the language of the manuals. Currently, Epson assembles and packs printers for sale in individual countries. The distribution of weekly demand in different countries is normally distributed, with means and standard deviations as shown in the following Table Assume demand in different countries to be independent. Given that the lead time from the Taiwan factory is eight weeks, how much safety inventory does Epson require in Europe if it targets a CSL of 95 percent? Epson decides to build a central DC in Europe. It will ship base printers (without power supply) to the DC. When an order is received, the DC will assemble power supplies, add manuals, and ship the printers to the appropriate country. The base printers are still to be manufactured in Taiwan with a lead time of eight weeks. How much saving of safety inventory can Epson expect as a result? Bonus Question (30) In the example 10-6 in Textbook (3 rd edition and 4th edition), the author offers a tailored aggregation method and achieved the total cost as $130,767. (This is the example 11-6 in 5th edition of the textbook). Can you find even better aggregated inventory policy which reduces the total cost