正在加载图片...

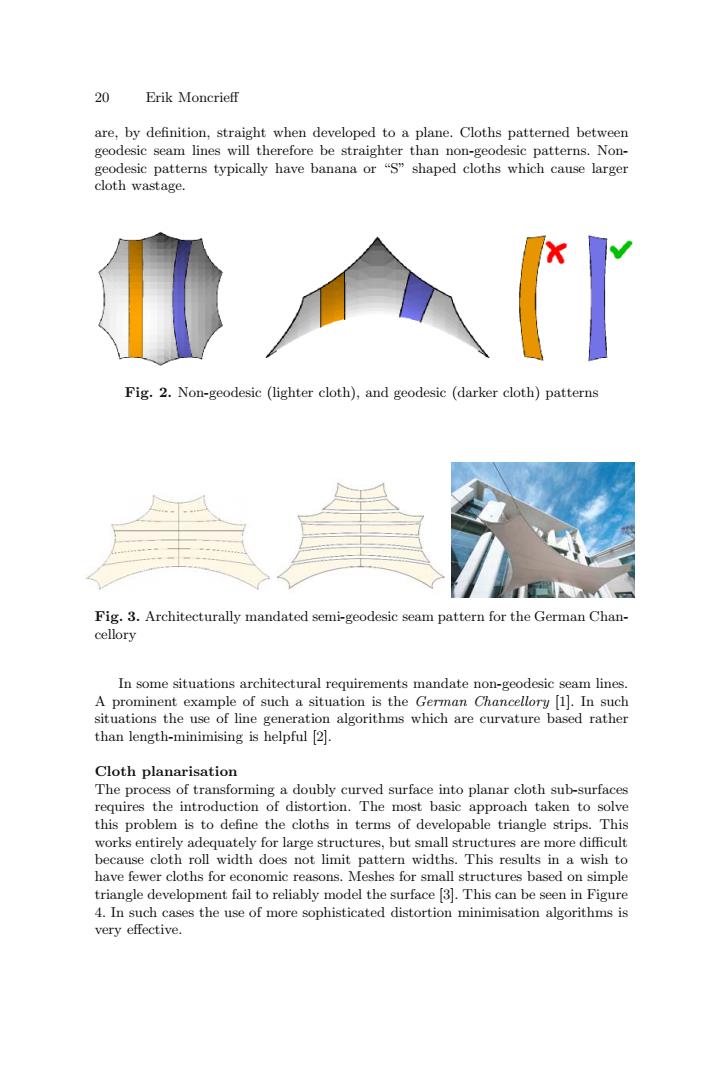

20 Erik Moncrieff are,by definition,straight when developed to a plane.Cloths patterned between geodesic seam lines will therefore be straighter than non-geodesic patterns.Non- geodesic patterns typically have banana or "S"shaped cloths which cause larger cloth wastage. Fig.2.Non-geodesic (lighter cloth),and geodesic (darker cloth)patterns Fig.3.Architecturally mandated semi-geodesic seam pattern for the German Chan- cellory In some situations architectural requirements mandate non-geodesic seam lines. A prominent example of such a situation is the German Chancellory [1].In such situations the use of line generation algorithms which are curvature based rather than length-minimising is helpful [2]. Cloth planarisation The process of transforming a doubly curved surface into planar cloth sub-surfaces requires the introduction of distortion.The most basic approach taken to solve this problem is to define the cloths in terms of developable triangle strips.This works entirely adequately for large structures,but small structures are more difficult because cloth roll width does not limit pattern widths.This results in a wish to have fewer cloths for economic reasons.Meshes for small structures based on simple triangle development fail to reliably model the surface [3].This can be seen in Figure 4.In such cases the use of more sophisticated distortion minimisation algorithms is very effective.20 Erik Moncrieff are, by definition, straight when developed to a plane. Cloths patterned between geodesic seam lines will therefore be straighter than non-geodesic patterns. Nongeodesic patterns typically have banana or “S” shaped cloths which cause larger cloth wastage. Fig. 2. Non-geodesic (lighter cloth), and geodesic (darker cloth) patterns Fig. 3. Architecturally mandated semi-geodesic seam pattern for the German Chancellory In some situations architectural requirements mandate non-geodesic seam lines. A prominent example of such a situation is the German Chancellory [1]. In such situations the use of line generation algorithms which are curvature based rather than length-minimising is helpful [2]. Cloth planarisation The process of transforming a doubly curved surface into planar cloth sub-surfaces requires the introduction of distortion. The most basic approach taken to solve this problem is to define the cloths in terms of developable triangle strips. This works entirely adequately for large structures, but small structures are more difficult because cloth roll width does not limit pattern widths. This results in a wish to have fewer cloths for economic reasons. Meshes for small structures based on simple triangle development fail to reliably model the surface [3]. This can be seen in Figure 4. In such cases the use of more sophisticated distortion minimisation algorithms is very effective