正在加载图片...

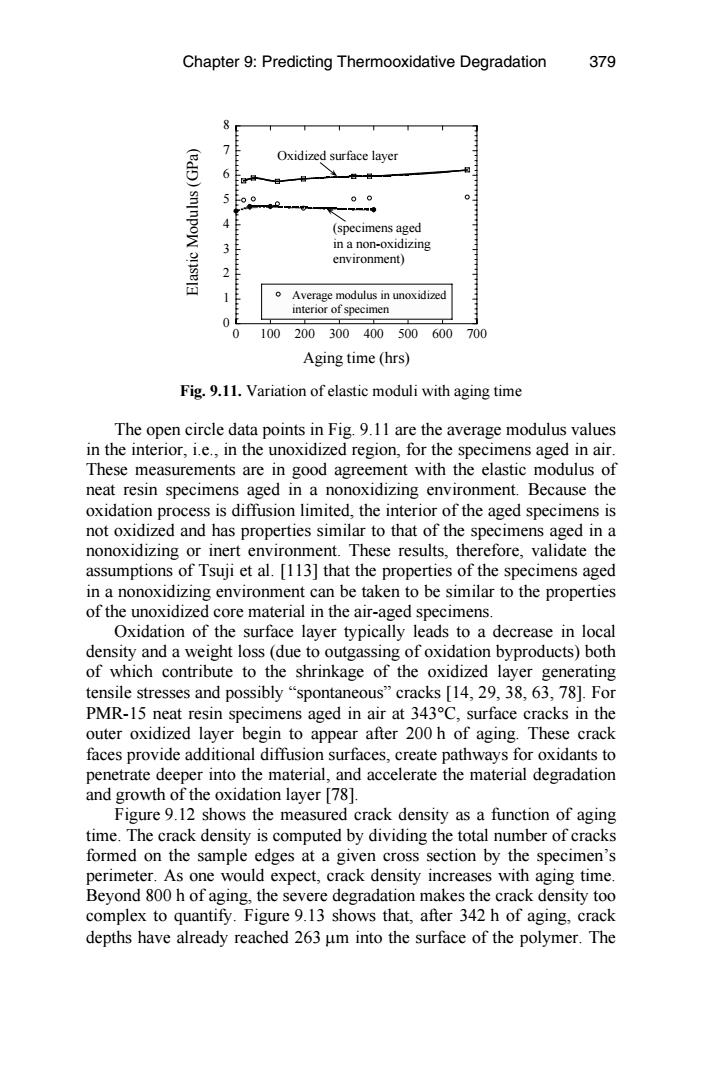

Chapter 9:Predicting Thermooxidative Degradation 379 () Oxidized surface layer 世 00 (specimens aged in a non-oxidizing environment) Average modulus in unoxidized interior of specimen 0 100 200300400500 600700 Aging time(hrs) Fig.9.11.Variation of elastic moduli with aging time The open circle data points in Fig.9.11 are the average modulus values in the interior,i.e.,in the unoxidized region,for the specimens aged in air. These measurements are in good agreement with the elastic modulus of neat resin specimens aged in a nonoxidizing environment.Because the oxidation process is diffusion limited,the interior of the aged specimens is not oxidized and has properties similar to that of the specimens aged in a nonoxidizing or inert environment.These results,therefore,validate the assumptions of Tsuji et al.[113]that the properties of the specimens aged in a nonoxidizing environment can be taken to be similar to the properties of the unoxidized core material in the air-aged specimens. Oxidation of the surface layer typically leads to a decrease in local density and a weight loss(due to outgassing of oxidation byproducts)both of which contribute to the shrinkage of the oxidized layer generating tensile stresses and possibly "spontaneous"cracks [14,29,38,63,78].For PMR-15 neat resin specimens aged in air at 343C,surface cracks in the outer oxidized layer begin to appear after 200 h of aging.These crack faces provide additional diffusion surfaces,create pathways for oxidants to penetrate deeper into the material,and accelerate the material degradation and growth of the oxidation layer [78]. Figure 9.12 shows the measured crack density as a function of aging time.The crack density is computed by dividing the total number of cracks formed on the sample edges at a given cross section by the specimen's perimeter.As one would expect,crack density increases with aging time. Beyond 800 h of aging,the severe degradation makes the crack density too complex to quantify.Figure 9.13 shows that,after 342 h of aging,crack depths have already reached 263 um into the surface of the polymer.TheFig. 9.11. Variation of elastic moduli with aging time The open circle data points in Fig. 9.11 are the average modulus values in the interior, i.e., in the unoxidized region, for the specimens aged in air. These measurements are in good agreement with the elastic modulus of neat resin specimens aged in a nonoxidizing environment. Because the oxidation process is diffusion limited, the interior of the aged specimens is not oxidized and has properties similar to that of the specimens aged in a nonoxidizing or inert environment. These results, therefore, validate the assumptions of Tsuji et al. [113] that the properties of the specimens aged in a nonoxidizing environment can be taken to be similar to the properties of the unoxidized core material in the air-aged specimens. Oxidation of the surface layer typically leads to a decrease in local density and a weight loss (due to outgassing of oxidation byproducts) both of which contribute to the shrinkage of the oxidized layer generating tensile stresses and possibly “spontaneous” cracks [14, 29, 38, 63, 78]. For PMR-15 neat resin specimens aged in air at 343°C, surface cracks in the outer oxidized layer begin to appear after 200 h of aging. These crack faces provide additional diffusion surfaces, create pathways for oxidants to penetrate deeper into the material, and accelerate the material degradation and growth of the oxidation layer [78]. Figure 9.12 shows the measured crack density as a function of aging time. The crack density is computed by dividing the total number of cracks formed on the sample edges at a given cross section by the specimen’s perimeter. As one would expect, crack density increases with aging time. Beyond 800 h of aging, the severe degradation makes the crack density too complex to quantify. Figure 9.13 shows that, after 342 h of aging, crack depths have already reached 263 µm into the surface of the polymer. The 0 1 2 3 4 5 6 7 8 0 100 200 300 400 500 600 700 Average modulus in unoxidized interior of specimen Elastic Modulus (GPa) Aging time (hrs) Oxidized surface layer (specimens aged in a non-oxidizing environment) Chapter 9: Predicting Thermooxidative Degradation 379