正在加载图片...

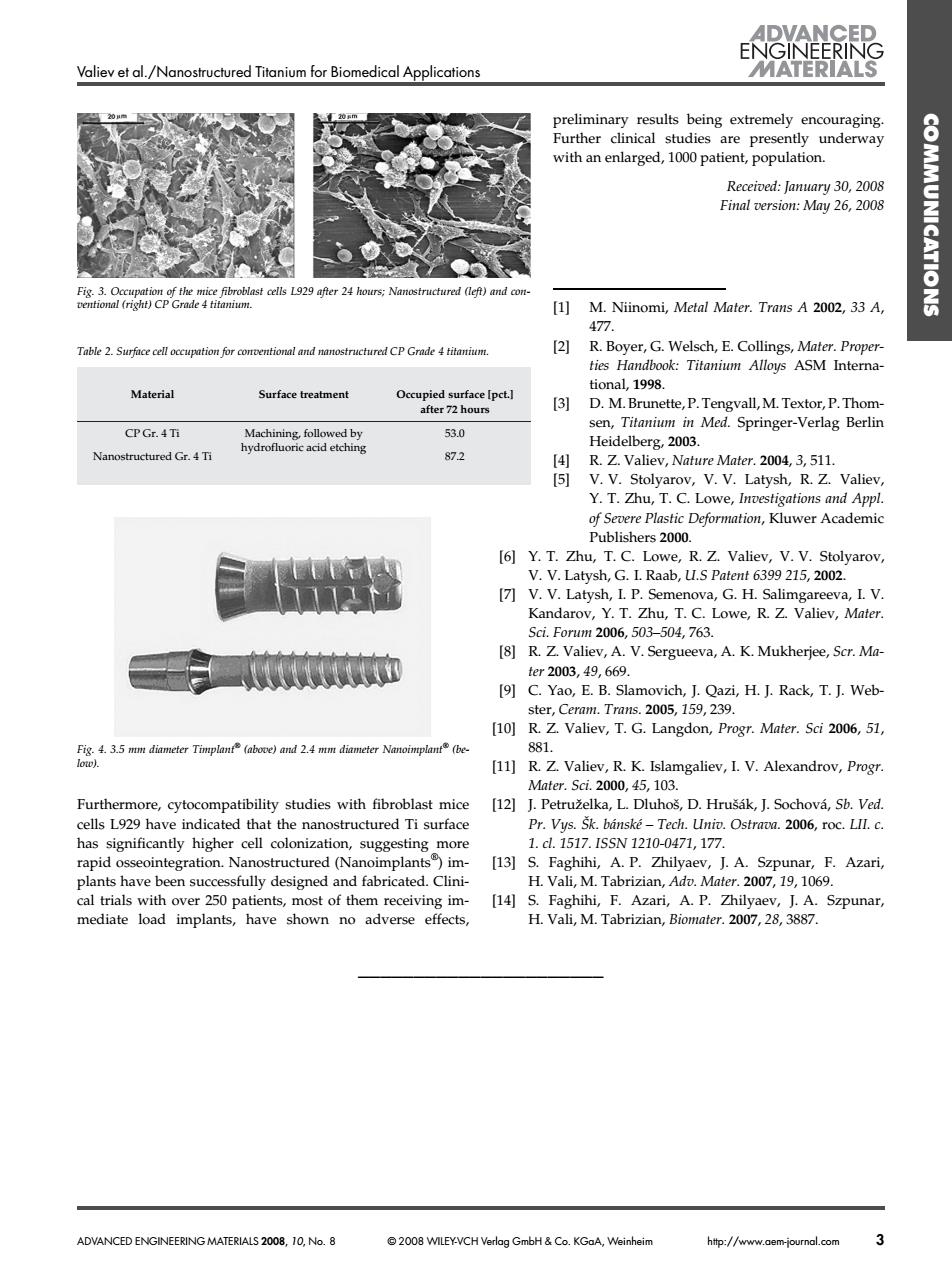

ADVANCED ENGINEERING Valiev et al./Nanostructured Titanium for Biomedical Applications MATERIALS preliminary results being extremely encouraging. Further clinical studies are presently underway with an enlarged,1000 patient,population. M Received:January 30,2008 Final version:May 26,2008 ATIO Fig.3.Occupation of the mice fibroblast cells 1929 after 24 hours;Nanostructured (left)and con- ventional (right)CP Grade 4 titanium. [ M.Niinomi,Metal Mater.Trans A 2002,33 A, 云 477. Table 2.Surface cell occupation for conventional and nanostructured CP Grade 4 titanium [21 R.Boyer,G.Welsch,E.Collings,Mater.Proper- ties Handbook:Titanium Alloys ASM Interna- tional,1998. Material Surface treatment Occupied surface Ipct.] after 72 hours [31 D.M.Brunette,P.Tengvall,M.Textor,P.Thom- CP Gr.4Ti Machining,followed by 53.0 sen,Titanium in Med.Springer-Verlag Berlin hydrofluoric acid etching Heidelberg,2003. Nanostructured Gr.4 Ti 872 [4]R.Z.Valiev,Nature Mater.2004,3,511. [5]V.V.Stolyarov,V.V.Latysh,R.Z.Valiev, Y.T.Zhu,T.C.Lowe,Investigations and Appl. of Severe Plastic Deformation,Kluwer Academic Publishers 2000. [6]Y.T.Zhu,T.C.Lowe,R.Z.Valiev,V.V.Stolyarov, V.V.Latysh,G.I.Raab,U.S Patent 6399 215,2002. [7]V.V.Latysh,I.P.Semenova,G.H.Salimgareeva,I.V. Kandarov,Y.T.Zhu,T.C.Lowe,R.Z.Valiev,Mater. Sci.F0rum2006,503-504,763. [8]R.Z.Valiev,A.V.Sergueeva,A.K.Mukherjee,Scr.Ma- ter200349,669. [9]C.Yao,E.B.Slamovich,J.Qazi,H.J.Rack,T.J.Web- ster,Ceram.Trans.2005,159,239. [10]R.Z.Valiev,T.G.Langdon,Progr.Mater.Sci 2006,51, Fig.4.3.5 mm diameter Timplan(above)and 2.4 mm diameter Nanoimplant (be 881. loe以. [11]R.Z.Valiev,R.K.Islamgaliev,I.V.Alexandrov,Progr. Mater..Sci.2000,45,103. Furthermore,cytocompatibility studies with fibroblast mice [12]J.Petruzelka,L.Dluhos,D.Hrusak,J.Sochova,Sb.Ved. cells L929 have indicated that the nanostructured Ti surface Pr.Vys.Sk.banske-Tech.Univ.Ostrava.2006,roc.LII.c. has significantly higher cell colonization,suggesting more 1.cd.1517.ISSN1210-0471,177. rapid osseointegration.Nanostructured(Nanoimplants)im- [13]S.Faghihi,A.P.Zhilyaev,J.A.Szpunar,F.Azari, plants have been successfully designed and fabricated.Clini- H.Vali,M.Tabrizian,Ado.Mater.2007,19,1069. cal trials with over 250 patients,most of them receiving im- [14]S.Faghihi,F.Azari,A.P.Zhilyaev,J.A.Szpunar, mediate load implants,have shown no adverse effects, H.Vali,M.Tabrizian,Biomater.2007,28,3887 ADVANCED ENGINEERING MATERIALS 2008,10,No.8 @2008 WILEY-VCH Verlag GmbH Co.KGaA,Weinheim http://www.aem-journal.comFurthermore, cytocompatibility studies with fibroblast mice cells L929 have indicated that the nanostructured Ti surface has significantly higher cell colonization, suggesting more rapid osseointegration. Nanostructured (Nanoimplants®) implants have been successfully designed and fabricated. Clinical trials with over 250 patients, most of them receiving immediate load implants, have shown no adverse effects, preliminary results being extremely encouraging. Further clinical studies are presently underway with an enlarged, 1000 patient, population. Received: January 30, 2008 Final version: May 26, 2008 – [1] M. Niinomi, Metal Mater. Trans A 2002, 33 A, 477. [2] R. Boyer, G. Welsch, E. Collings, Mater. Properties Handbook: Titanium Alloys ASM International, 1998. [3] D. M. Brunette, P. Tengvall, M. Textor, P. Thomsen, Titanium in Med. Springer-Verlag Berlin Heidelberg, 2003. [4] R. Z. Valiev, Nature Mater. 2004, 3, 511. [5] V. V. Stolyarov, V. V. Latysh, R. Z. Valiev, Y. T. Zhu, T. C. Lowe, Investigations and Appl. of Severe Plastic Deformation, Kluwer Academic Publishers 2000. [6] Y. T. Zhu, T. C. Lowe, R. Z. Valiev, V. V. Stolyarov, V. V. Latysh, G. I. Raab, U.S Patent 6399 215, 2002. [7] V. V. Latysh, I. P. Semenova, G. H. Salimgareeva, I. V. Kandarov, Y. T. Zhu, T. C. Lowe, R. Z. Valiev, Mater. Sci. Forum 2006, 503–504, 763. [8] R. Z. Valiev, A. V. Sergueeva, A. K. Mukherjee, Scr. Mater 2003, 49, 669. [9] C. Yao, E. B. Slamovich, J. Qazi, H. J. Rack, T. J. Webster, Ceram. Trans. 2005, 159, 239. [10] R. Z. Valiev, T. G. Langdon, Progr. Mater. Sci 2006, 51, 881. [11] R. Z. Valiev, R. K. Islamgaliev, I. V. Alexandrov, Progr. Mater. Sci. 2000, 45, 103. [12] J. Petruzˇelka, L. Dluhoš, D. Hrušák, J. Sochová, Sb. Ved. Pr. Vys. Šk. bánské – Tech. Univ. Ostrava. 2006, roc. LII. c. 1. cl. 1517. ISSN 1210-0471, 177. [13] S. Faghihi, A. P. Zhilyaev, J. A. Szpunar, F. Azari, H. Vali, M. Tabrizian, Adv. Mater. 2007, 19, 1069. [14] S. Faghihi, F. Azari, A. P. Zhilyaev, J. A. Szpunar, H. Vali, M. Tabrizian, Biomater. 2007, 28, 3887. ______________________ Valiev et al./Nanostructured Titanium for Biomedical Applications COMMUNICATIONS ADVANCED ENGINEERING MATERIALS 2008, 10, No. 8 © 2008 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim http://www.aem-journal.com 3 Table 2. Surface cell occupation for conventional and nanostructured CP Grade 4 titanium. Material Surface treatment Occupied surface [pct.] after 72 hours CP Gr. 4 Ti Machining, followed by hydrofluoric acid etching 53.0 Nanostructured Gr. 4 Ti 87.2 Fig. 3. Occupation of the mice fibroblast cells L929 after 24 hours; Nanostructured (left) and conventional (right) CP Grade 4 titanium. Fig. 4. 3.5 mm diameter Timplant® (above) and 2.4 mm diameter Nanoimplant® (below)