正在加载图片...

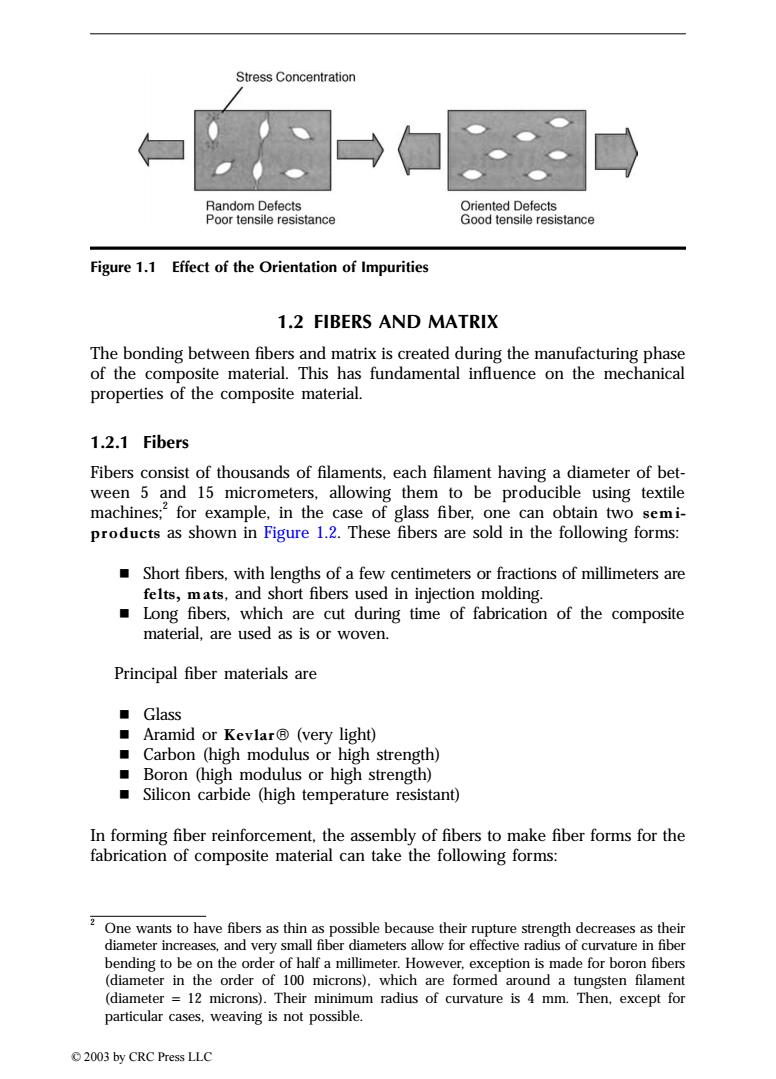

Stress Concentration Random Defects Oriented Defects Poor tensile resistance Good tensile resistance Figure 1.1 Effect of the Orientation of Impurities 1.2 FIBERS AND MATRIX The bonding between fibers and matrix is created during the manufacturing phase of the composite material.This has fundamental influence on the mechanical properties of the composite material. 1.2.1 Fibers Fibers consist of thousands of filaments,each filament having a diameter of bet- ween 5 and 15 micrometers,allowing them to be producible using textile machines;for example,in the case of glass fiber,one can obtain two semi- products as shown in Figure 1.2.These fibers are sold in the following forms: Short fibers,with lengths of a few centimeters or fractions of millimeters are felts,mats,and short fibers used in injection molding. Long fibers,which are cut during time of fabrication of the composite material,are used as is or woven. Principal fiber materials are ■Glass Aramid or Kevlar(very light) Carbon (high modulus or high strength) Boron (high modulus or high strength) Silicon carbide (high temperature resistant) In forming fiber reinforcement,the assembly of fibers to make fiber forms for the fabrication of composite material can take the following forms: One wants to have fibers as thin as possible because their rupture strength decreases as their diameter increases,and very small fiber diameters allow for effective radius of curvature in fiber bending to be on the order of half a millimeter.However,exception is made for boron fibers (diameter in the order of 100 microns).which are formed around a tungsten filament (diameter 12 microns).Their minimum radius of curvature is 4 mm.Then,except for particular cases,weaving is not possible. 2003 by CRC Press LLC1.2 FIBERS AND MATRIX The bonding between fibers and matrix is created during the manufacturing phase of the composite material. This has fundamental influence on the mechanical properties of the composite material. 1.2.1 Fibers Fibers consist of thousands of filaments, each filament having a diameter of between 5 and 15 micrometers, allowing them to be producible using textile machines;2 for example, in the case of glass fiber, one can obtain two semiproducts as shown in Figure 1.2. These fibers are sold in the following forms: Short fibers, with lengths of a few centimeters or fractions of millimeters are felts, mats, and short fibers used in injection molding. Long fibers, which are cut during time of fabrication of the composite material, are used as is or woven. Principal fiber materials are Glass Aramid or Kevlar‚ (very light) Carbon (high modulus or high strength) Boron (high modulus or high strength) Silicon carbide (high temperature resistant) In forming fiber reinforcement, the assembly of fibers to make fiber forms for the fabrication of composite material can take the following forms: Figure 1.1 Effect of the Orientation of Impurities 2 One wants to have fibers as thin as possible because their rupture strength decreases as their diameter increases, and very small fiber diameters allow for effective radius of curvature in fiber bending to be on the order of half a millimeter. However, exception is made for boron fibers (diameter in the order of 100 microns), which are formed around a tungsten filament (diameter = 12 microns). Their minimum radius of curvature is 4 mm. Then, except for particular cases, weaving is not possible. TX846_Frame_C01 Page 4 Monday, November 18, 2002 10:34 AM © 2003 by CRC Press LLC