正在加载图片...

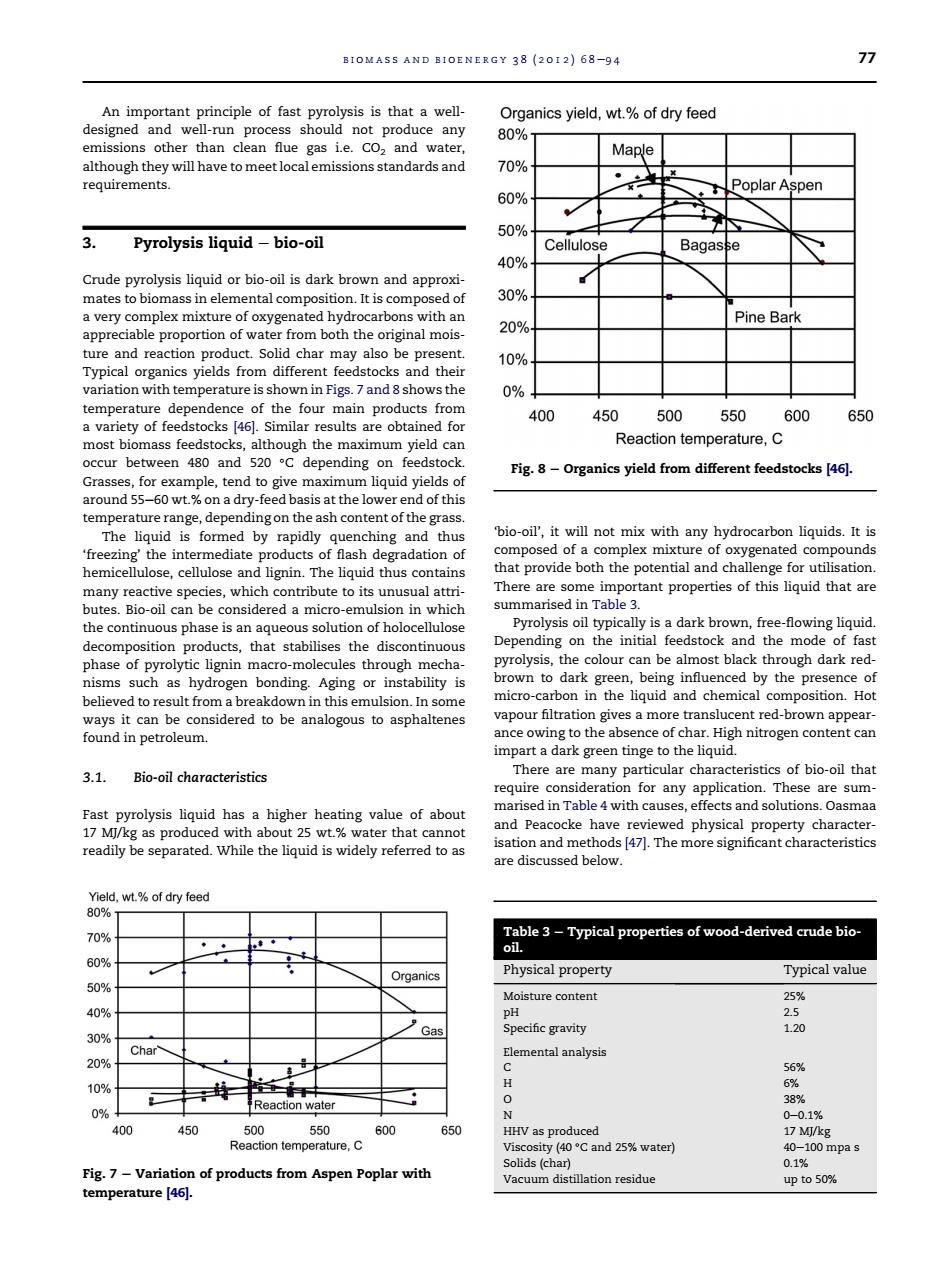

BIOMASS AND BIOENERGY 38 (2012)68-94 77 An important principle of fast pyrolysis is that a well- Organics yield,wt.%of dry feed designed and well-run process should not produce any 80% emissions other than clean flue gas i.e.COz and water, Maple although they will have to meet local emissions standards and 70% requirements. Poplar Aspen 60% 50% Pyrolysis liquid-bio-oil Cellulose Bagasse 40% Crude pyrolysis liquid or bio-oil is dark brown and approxi- mates to biomass in elemental composition.It is composed of 30% a very complex mixture of oxygenated hydrocarbons with an Pine Bark appreciable proportion of water from both the original mois- 20% ture and reaction product.Solid char may also be present. 10% Typical organics yields from different feedstocks and their variation with temperature is shown in Figs.7 and 8 shows the 0% temperature dependence of the four main products from 400 450 500 550 600 650 a variety of feedstocks [46].Similar results are obtained for most biomass feedstocks,although the maximum yield can Reaction temperature,C occur between 480 and 520C depending on feedstock. Fig.8-Organics yield from different feedstocks [46]. Grasses,for example,tend to give maximum liquid yields of around 55-60 wt.%on a dry-feed basis at the lower end of this temperature range,dependingon the ash content of the grass. The liquid is formed by rapidly quenching and thus bio-oil',it will not mix with any hydrocarbon liquids.It is freezing'the intermediate products of flash degradation of composed of a complex mixture of oxygenated compounds hemicellulose,cellulose and lignin.The liquid thus contains that provide both the potential and challenge for utilisation. many reactive species,which contribute to its unusual attri- There are some important properties of this liquid that are butes.Bio-oil can be considered a micro-emulsion in which summarised in Table 3. the continuous phase is an aqueous solution of holocellulose Pyrolysis oil typically is a dark brown,free-flowing liquid decomposition products,that stabilises the discontinuous Depending on the initial feedstock and the mode of fast phase of pyrolytic lignin macro-molecules through mecha- pyrolysis,the colour can be almost black through dark red- nisms such as hydrogen bonding.Aging or instability is brown to dark green,being influenced by the presence of believed to result from a breakdown in this emulsion.In some micro-carbon in the liquid and chemical composition.Hot ways it can be considered to be analogous to asphaltenes vapour filtration gives a more translucent red-brown appear- found in petroleum. ance owing to the absence of char.High nitrogen content can impart a dark green tinge to the liquid. 3.1. Bio-oil characteristics There are many particular characteristics of bio-oil that require consideration for any application.These are sum- marised in Table 4 with causes,effects and solutions.Oasmaa Fast pyrolysis liquid has a higher heating value of about 17 MJ/kg as produced with about 25 wt.%water that cannot and Peacocke have reviewed physical property character- readily be separated.While the liquid is widely referred to as isation and methods [47].The more significant characteristics are discussed below. Yield,wt.%of dry feed 80% 70% Table 3-Typical properties of wood-derived crude bio- oil. 60% Organics Physical property Typical value 50% Moisture content 25% 40% pH 2.5 Gas Specific gravity 1.20 30% Char Elemental analysis 20% C 56% 10% H 6% 0 38% Reaction water 0% N 0-0.1% 400 450 500 550 600 650 HHV as produced 17 MJ/kg Reaction temperature,C Viscosity (40C and 25%water) 40-100mpas Solids(char) 0.1% Fig.7-Variation of products from Aspen Poplar with Vacuum distillation residue up to 50% temperature【46.An important principle of fast pyrolysis is that a welldesigned and well-run process should not produce any emissions other than clean flue gas i.e. CO2 and water, although they will have to meet local emissions standards and requirements. 3. Pyrolysis liquid e bio-oil Crude pyrolysis liquid or bio-oil is dark brown and approximates to biomass in elemental composition. It is composed of a very complex mixture of oxygenated hydrocarbons with an appreciable proportion of water from both the original moisture and reaction product. Solid char may also be present. Typical organics yields from different feedstocks and their variation with temperature is shown in Figs. 7 and 8 shows the temperature dependence of the four main products from a variety of feedstocks [46]. Similar results are obtained for most biomass feedstocks, although the maximum yield can occur between 480 and 520 C depending on feedstock. Grasses, for example, tend to give maximum liquid yields of around 55e60 wt.% on a dry-feed basis at the lower end of this temperature range, depending on the ash content of the grass. The liquid is formed by rapidly quenching and thus ‘freezing’ the intermediate products of flash degradation of hemicellulose, cellulose and lignin. The liquid thus contains many reactive species, which contribute to its unusual attributes. Bio-oil can be considered a micro-emulsion in which the continuous phase is an aqueous solution of holocellulose decomposition products, that stabilises the discontinuous phase of pyrolytic lignin macro-molecules through mechanisms such as hydrogen bonding. Aging or instability is believed to result from a breakdown in this emulsion. In some ways it can be considered to be analogous to asphaltenes found in petroleum. 3.1. Bio-oil characteristics Fast pyrolysis liquid has a higher heating value of about 17 MJ/kg as produced with about 25 wt.% water that cannot readily be separated. While the liquid is widely referred to as ‘bio-oil’, it will not mix with any hydrocarbon liquids. It is composed of a complex mixture of oxygenated compounds that provide both the potential and challenge for utilisation. There are some important properties of this liquid that are summarised in Table 3. Pyrolysis oil typically is a dark brown, free-flowing liquid. Depending on the initial feedstock and the mode of fast pyrolysis, the colour can be almost black through dark redbrown to dark green, being influenced by the presence of micro-carbon in the liquid and chemical composition. Hot vapour filtration gives a more translucent red-brown appearance owing to the absence of char. High nitrogen content can impart a dark green tinge to the liquid. There are many particular characteristics of bio-oil that require consideration for any application. These are summarised in Table 4 with causes, effects and solutions. Oasmaa and Peacocke have reviewed physical property characterisation and methods [47]. The more significant characteristics are discussed below. Fig. 7 e Variation of products from Aspen Poplar with temperature [46]. Fig. 8 e Organics yield from different feedstocks [46]. Table 3 e Typical properties of wood-derived crude biooil. Physical property Typical value Moisture content 25% pH 2.5 Specific gravity 1.20 Elemental analysis C 56% H 6% O 38% N 0e0.1% HHV as produced 17 MJ/kg Viscosity (40 C and 25% water) 40e100 mpa s Solids (char) 0.1% Vacuum distillation residue up to 50% biomass and bioenergy 38 (2012) 68 e9 4 77