正在加载图片...

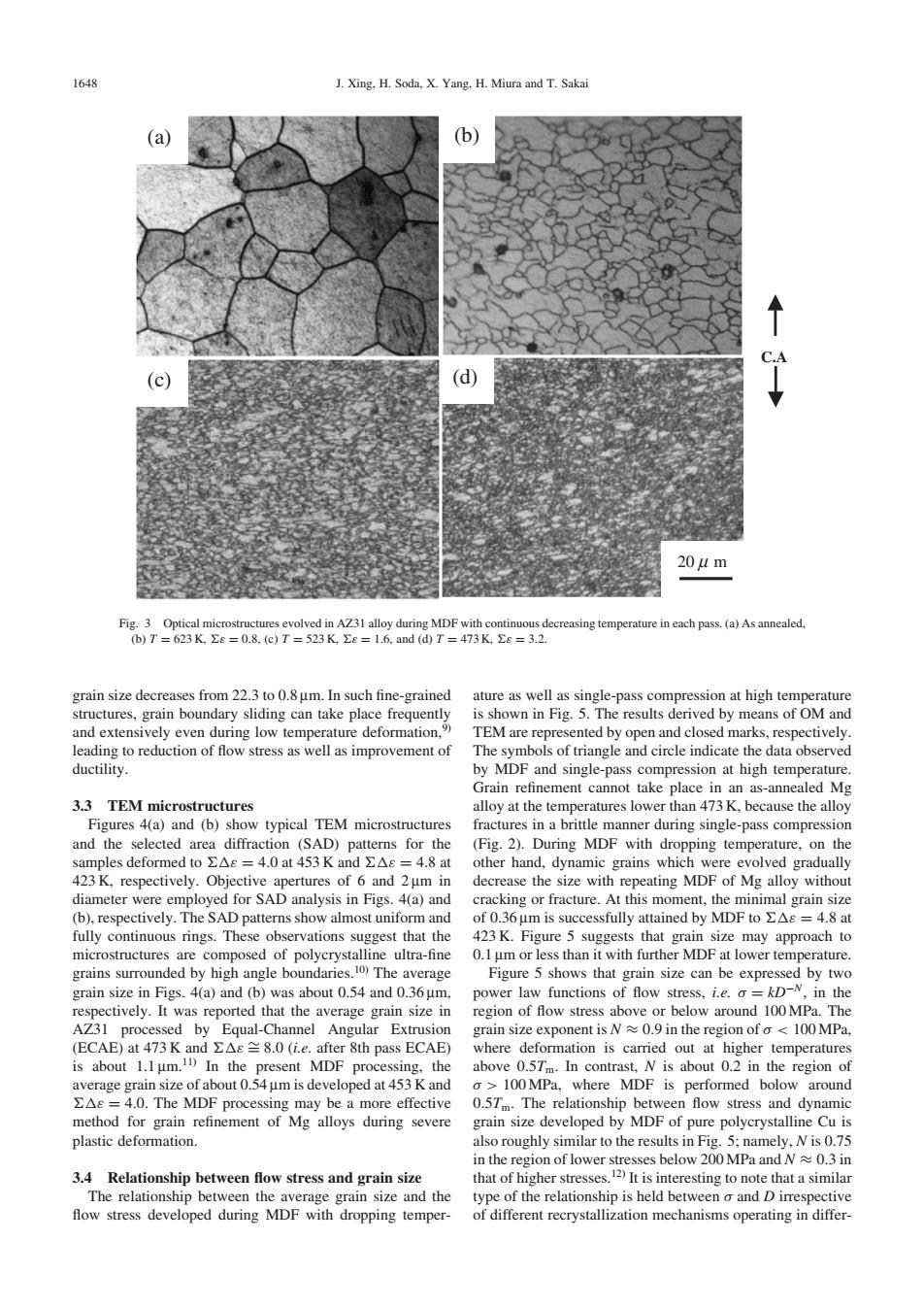

1648 J.Xing,H.Soda,X.Yang,H.Miura and T.Sakai a ↑ (c) (d) ↓ 204m Fig.3 Optical microstructures evolved in AZ31 alloy during MDF with continuous decreasing temperature in each pass.(a)As annealed, b)T=623K,E8=0.8.(c)T=523KEe=1.6.and(d)T=473K,∑e=3.2. grain size decreases from 22.3 to 0.8um.In such fine-grained ature as well as single-pass compression at high temperature structures,grain boundary sliding can take place frequently is shown in Fig.5.The results derived by means of OM and and extensively even during low temperature deformation, TEM are represented by open and closed marks,respectively. leading to reduction of flow stress as well as improvement of The symbols of triangle and circle indicate the data observed ductility. by MDF and single-pass compression at high temperature. Grain refinement cannot take place in an as-annealed Mg 3.3 TEM microstructures alloy at the temperatures lower than 473 K,because the alloy Figures 4(a)and (b)show typical TEM microstructures fractures in a brittle manner during single-pass compression and the selected area diffraction (SAD)patterns for the (Fig.2).During MDF with dropping temperature,on the samples deformed to∑△e=4.0at453Kand∑△e=4.8at other hand,dynamic grains which were evolved gradually 423 K,respectively.Objective apertures of 6 and 2um in decrease the size with repeating MDF of Mg alloy without diameter were employed for SAD analysis in Figs.4(a)and cracking or fracture.At this moment,the minimal grain size (b),respectively.The SAD patterns show almost uniform and of 0.36 um is successfully attained by MDF to EAs =4.8 at fully continuous rings.These observations suggest that the 423 K.Figure 5 suggests that grain size may approach to microstructures are composed of polycrystalline ultra-fine 0.1 um or less than it with further MDF at lower temperature. grains surrounded by high angle boundaries.10)The average Figure 5 shows that grain size can be expressed by two grain size in Figs.4(a)and (b)was about 0.54 and 0.36um, power law functions of flow stress,i.e.o=kD-N,in the respectively.It was reported that the average grain size in region of flow stress above or below around 100MPa.The AZ31 processed by Equal-Channel Angular Extrusion grain size exponent is N0.9 in the region of o 100 MPa, (ECAE)at473Kand∑△e兰8.0(i.e.after8 th pass ECAE) where deformation is carried out at higher temperatures is about 1.1um.1)In the present MDF processing,the above 0.5Tm.In contrast,N is about 0.2 in the region of average grain size of about 0.54 um is developed at 453 K and >100 MPa,where MDF is performed bolow around EAs=4.0.The MDF processing may be a more effective 0.57m.The relationship between flow stress and dynamid method for grain refinement of Mg alloys during severe grain size developed by MDF of pure polycrystalline Cu is plastic deformation also roughly similar to the results in Fig.5;namely,N is 0.75 in the region of lower stresses below 200 MPa and N0.3 in 3.4 Relationship between flow stress and grain size that of higher stresses.2)It is interesting to note that a similar The relationship between the average grain size and the type of the relationship is held between o and D irrespective flow stress developed during MDF with dropping temper- of different recrystallization mechanisms operating in differ-grain size decreases from 22.3 to 0.8 mm. In such fine-grained structures, grain boundary sliding can take place frequently and extensively even during low temperature deformation,9) leading to reduction of flow stress as well as improvement of ductility. 3.3 TEM microstructures Figures 4(a) and (b) show typical TEM microstructures and the selected area diffraction (SAD) patterns for the samples deformed to " ¼ 4:0 at 453 K and " ¼ 4:8 at 423 K, respectively. Objective apertures of 6 and 2 mm in diameter were employed for SAD analysis in Figs. 4(a) and (b), respectively. The SAD patterns show almost uniform and fully continuous rings. These observations suggest that the microstructures are composed of polycrystalline ultra-fine grains surrounded by high angle boundaries.10) The average grain size in Figs. 4(a) and (b) was about 0.54 and 0.36 mm, respectively. It was reported that the average grain size in AZ31 processed by Equal-Channel Angular Extrusion (ECAE) at 473 K and " ¼ 8:0 (i.e. after 8th pass ECAE) is about 1.1 mm. 11) In the present MDF processing, the average grain size of about 0.54 mm is developed at 453 K and " ¼ 4:0. The MDF processing may be a more effective method for grain refinement of Mg alloys during severe plastic deformation. 3.4 Relationship between flow stress and grain size The relationship between the average grain size and the flow stress developed during MDF with dropping temperature as well as single-pass compression at high temperature is shown in Fig. 5. The results derived by means of OM and TEM are represented by open and closed marks, respectively. The symbols of triangle and circle indicate the data observed by MDF and single-pass compression at high temperature. Grain refinement cannot take place in an as-annealed Mg alloy at the temperatures lower than 473 K, because the alloy fractures in a brittle manner during single-pass compression (Fig. 2). During MDF with dropping temperature, on the other hand, dynamic grains which were evolved gradually decrease the size with repeating MDF of Mg alloy without cracking or fracture. At this moment, the minimal grain size of 0.36 mm is successfully attained by MDF to " ¼ 4:8 at 423 K. Figure 5 suggests that grain size may approach to 0.1 mm or less than it with further MDF at lower temperature. Figure 5 shows that grain size can be expressed by two power law functions of flow stress, i.e. ¼ kDN, in the region of flow stress above or below around 100 MPa. The grain size exponent is N 0:9 in the region of < 100 MPa, where deformation is carried out at higher temperatures above 0:5Tm. In contrast, N is about 0.2 in the region of > 100 MPa, where MDF is performed bolow around 0:5Tm. The relationship between flow stress and dynamic grain size developed by MDF of pure polycrystalline Cu is also roughly similar to the results in Fig. 5; namely, N is 0.75 in the region of lower stresses below 200 MPa and N 0:3 in that of higher stresses.12) It is interesting to note that a similar type of the relationship is held between and D irrespective of different recrystallization mechanisms operating in differC.A (a) (b) (c) (d) 20 m µ Fig. 3 Optical microstructures evolved in AZ31 alloy during MDF with continuous decreasing temperature in each pass. (a) As annealed, (b) T ¼ 623 K, " ¼ 0:8, (c) T ¼ 523 K, " ¼ 1:6, and (d) T ¼ 473 K, " ¼ 3:2. 1648 J. Xing, H. Soda, X. Yang, H. Miura and T. Sakai���������