正在加载图片...

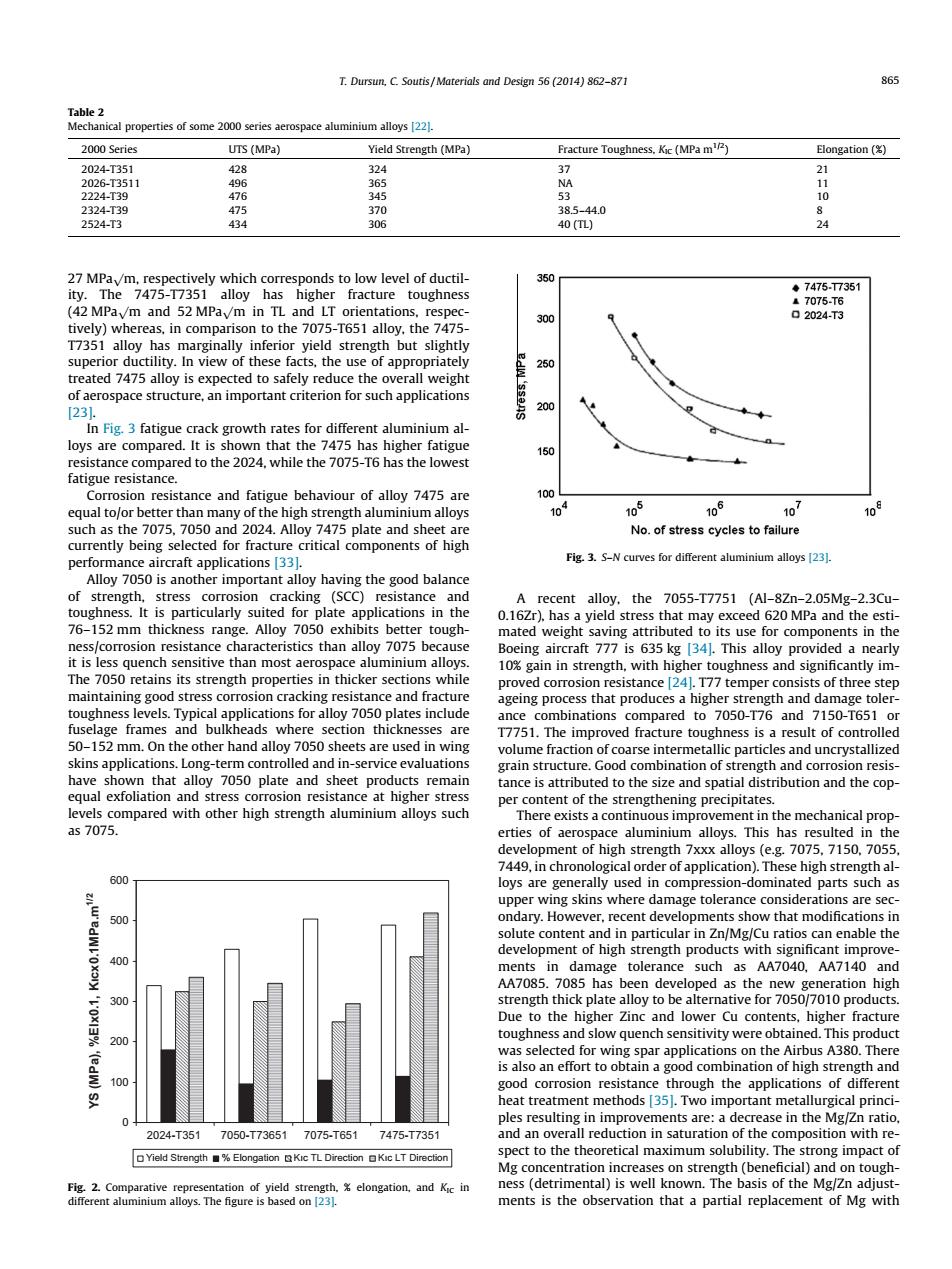

T.Dursun.C.Soutis/Materials and Design 56(2014)862-871 865 Table 2 Mechanical properties of some 2000 series aerospace aluminium alloys [221. 2000 Series UTS(MPa) Yield Strength(MPa) Fracture Toughness.Kic(MPa m'R) Elongation ( 2024-T351 428 324 37 1 2026-T3511 496 365 NA 11 2224-T39 476 345 0 2324-T39 475 370 38.5-44.0 8 2524-T3 434 306 40(TL) 24 27 MPaym,respectively which corresponds to low level of ductil- 350 ity.The 7475-T7351 alloy has higher fracture toughness ◆7475-7351 ▲7075T6 (42 MPaym and 52 MPay/m in TL and LT orientations,respec- 300 02024-T3 tively)whereas,in comparison to the 7075-T651 alloy,the 7475- T7351 alloy has marginally inferior yield strength but slightly superior ductility.In view of these facts,the use of appropriately EdW'ssans 250 treated 7475 alloy is expected to safely reduce the overall weight of aerospace structure,an important criterion for such applications [231. 200 In Fig.3 fatigue crack growth rates for different aluminium al- loys are compared.It is shown that the 7475 has higher fatigue 150 resistance compared to the 2024,while the 7075-T6 has the lowest fatigue resistance. Corrosion resistance and fatigue behaviour of alloy 7475 are 100 equal to/or better than many of the high strength aluminium alloys 10 105 105 10 10 such as the 7075,7050 and 2024.Alloy 7475 plate and sheet are No.of stress cycles to failure currently being selected for fracture critical components of high performance aircraft applications [33]. Fig.3.S-N curves for different aluminium alloys [23]. Alloy 7050 is another important alloy having the good balance of strength,stress corrosion cracking (SCC)resistance and A recent alloy,the 7055-T7751 (Al-8Zn-2.05Mg-2.3Cu- toughness.It is particularly suited for plate applications in the 0.16Zr).has a yield stress that may exceed 620 MPa and the esti- 76-152 mm thickness range.Alloy 7050 exhibits better tough- mated weight saving attributed to its use for components in the ness/corrosion resistance characteristics than alloy 7075 because Boeing aircraft 777 is 635 kg 341.This alloy provided a nearly it is less quench sensitive than most aerospace aluminium alloys. 10%gain in strength,with higher toughness and significantly im- The 7050 retains its strength properties in thicker sections while proved corrosion resistance [24].T77 temper consists of three step maintaining good stress corrosion cracking resistance and fracture ageing process that produces a higher strength and damage toler- toughness levels.Typical applications for alloy 7050 plates include ance combinations compared to 7050-T76 and 7150-T651 or fuselage frames and bulkheads where section thicknesses are 17751.The improved fracture toughness is a result of controlled 50-152 mm.On the other hand alloy 7050 sheets are used in wing volume fraction of coarse intermetallic particles and uncrystallized skins applications.Long-term controlled and in-service evaluations grain structure.Good combination of strength and corrosion resis- have shown that alloy 7050 plate and sheet products remain tance is attributed to the size and spatial distribution and the cop- equal exfoliation and stress corrosion resistance at higher stress per content of the strengthening precipitates. levels compared with other high strength aluminium alloys such There exists a continuous improvement in the mechanical prop- as7075. erties of aerospace aluminium alloys.This has resulted in the development of high strength 7xxx alloys(e.g.7075,7150,7055. 7449,in chronological order of application).These high strength al- 600 loys are generally used in compression-dominated parts such as upper wing skins where damage tolerance considerations are sec- 500 ondary.However,recent developments show that modifications in solute content and in particular in Zn/Mg/Cu ratios can enable the development of high strength products with significant improve- 400 ments in damage tolerance such as AA7040,AA7140 and AA7085.7085 has been developed as the new generation high 300 strength thick plate alloy to be alternative for 7050/7010 products. Due to the higher Zinc and lower Cu contents,higher fracture 200 toughness and slow quench sensitivity were obtained.This product was selected for wing spar applications on the Airbus A380.There (edw) is also an effort to obtain a good combination of high strength and 100 good corrosion resistance through the applications of different heat treatment methods [35].Two important metallurgical princi- ples resulting in improvements are:a decrease in the Mg/Zn ratio. 2024.T351 7050-T73651 7075-T651 7475-T7351 and an overall reduction in saturation of the composition with re- Yield Strength%Elongation KIc TL Direction Kic LT Direction spect to the theoretical maximum solubility.The strong impact of Mg concentration increases on strength(beneficial)and on tough- Fig.2.Comparative representation of yield strength.%elongation,and Kic in ness (detrimental)is well known.The basis of the Mg/Zn adjust- different aluminium alloys.The figure is based on [23]. ments is the observation that a partial replacement of Mg with27 MPapm, respectively which corresponds to low level of ductility. The 7475-T7351 alloy has higher fracture toughness (42 MPapm and 52 MPapm in TL and LT orientations, respectively) whereas, in comparison to the 7075-T651 alloy, the 7475- T7351 alloy has marginally inferior yield strength but slightly superior ductility. In view of these facts, the use of appropriately treated 7475 alloy is expected to safely reduce the overall weight of aerospace structure, an important criterion for such applications [23]. In Fig. 3 fatigue crack growth rates for different aluminium alloys are compared. It is shown that the 7475 has higher fatigue resistance compared to the 2024, while the 7075-T6 has the lowest fatigue resistance. Corrosion resistance and fatigue behaviour of alloy 7475 are equal to/or better than many of the high strength aluminium alloys such as the 7075, 7050 and 2024. Alloy 7475 plate and sheet are currently being selected for fracture critical components of high performance aircraft applications [33]. Alloy 7050 is another important alloy having the good balance of strength, stress corrosion cracking (SCC) resistance and toughness. It is particularly suited for plate applications in the 76–152 mm thickness range. Alloy 7050 exhibits better toughness/corrosion resistance characteristics than alloy 7075 because it is less quench sensitive than most aerospace aluminium alloys. The 7050 retains its strength properties in thicker sections while maintaining good stress corrosion cracking resistance and fracture toughness levels. Typical applications for alloy 7050 plates include fuselage frames and bulkheads where section thicknesses are 50–152 mm. On the other hand alloy 7050 sheets are used in wing skins applications. Long-term controlled and in-service evaluations have shown that alloy 7050 plate and sheet products remain equal exfoliation and stress corrosion resistance at higher stress levels compared with other high strength aluminium alloys such as 7075. A recent alloy, the 7055-T7751 (Al–8Zn–2.05Mg–2.3Cu– 0.16Zr), has a yield stress that may exceed 620 MPa and the estimated weight saving attributed to its use for components in the Boeing aircraft 777 is 635 kg [34]. This alloy provided a nearly 10% gain in strength, with higher toughness and significantly improved corrosion resistance [24]. T77 temper consists of three step ageing process that produces a higher strength and damage tolerance combinations compared to 7050-T76 and 7150-T651 or T7751. The improved fracture toughness is a result of controlled volume fraction of coarse intermetallic particles and uncrystallized grain structure. Good combination of strength and corrosion resistance is attributed to the size and spatial distribution and the copper content of the strengthening precipitates. There exists a continuous improvement in the mechanical properties of aerospace aluminium alloys. This has resulted in the development of high strength 7xxx alloys (e.g. 7075, 7150, 7055, 7449, in chronological order of application). These high strength alloys are generally used in compression-dominated parts such as upper wing skins where damage tolerance considerations are secondary. However, recent developments show that modifications in solute content and in particular in Zn/Mg/Cu ratios can enable the development of high strength products with significant improvements in damage tolerance such as AA7040, AA7140 and AA7085. 7085 has been developed as the new generation high strength thick plate alloy to be alternative for 7050/7010 products. Due to the higher Zinc and lower Cu contents, higher fracture toughness and slow quench sensitivity were obtained. This product was selected for wing spar applications on the Airbus A380. There is also an effort to obtain a good combination of high strength and good corrosion resistance through the applications of different heat treatment methods [35]. Two important metallurgical principles resulting in improvements are: a decrease in the Mg/Zn ratio, and an overall reduction in saturation of the composition with respect to the theoretical maximum solubility. The strong impact of Mg concentration increases on strength (beneficial) and on toughness (detrimental) is well known. The basis of the Mg/Zn adjustments is the observation that a partial replacement of Mg with Table 2 Mechanical properties of some 2000 series aerospace aluminium alloys [22]. 2000 Series UTS (MPa) Yield Strength (MPa) Fracture Toughness, KIC (MPa m1/2) Elongation (%) 2024-T351 428 324 37 21 2026-T3511 496 365 NA 11 2224-T39 476 345 53 10 2324-T39 475 370 38.5–44.0 8 2524-T3 434 306 40 (TL) 24 0 100 200 300 400 500 600 2024-T351 7050-T73651 7075-T651 7475-T7351 YS (MPa), %Elx0.1, Kıcx0.1MPa.m1/2 Yield Strength % Elongation Kıc TL Direction Kıc LT Direction Fig. 2. Comparative representation of yield strength, % elongation, and KIC in different aluminium alloys. The figure is based on [23]. Fig. 3. S–N curves for different aluminium alloys [23]. T. Dursun, C. Soutis / Materials and Design 56 (2014) 862–871 865