正在加载图片...

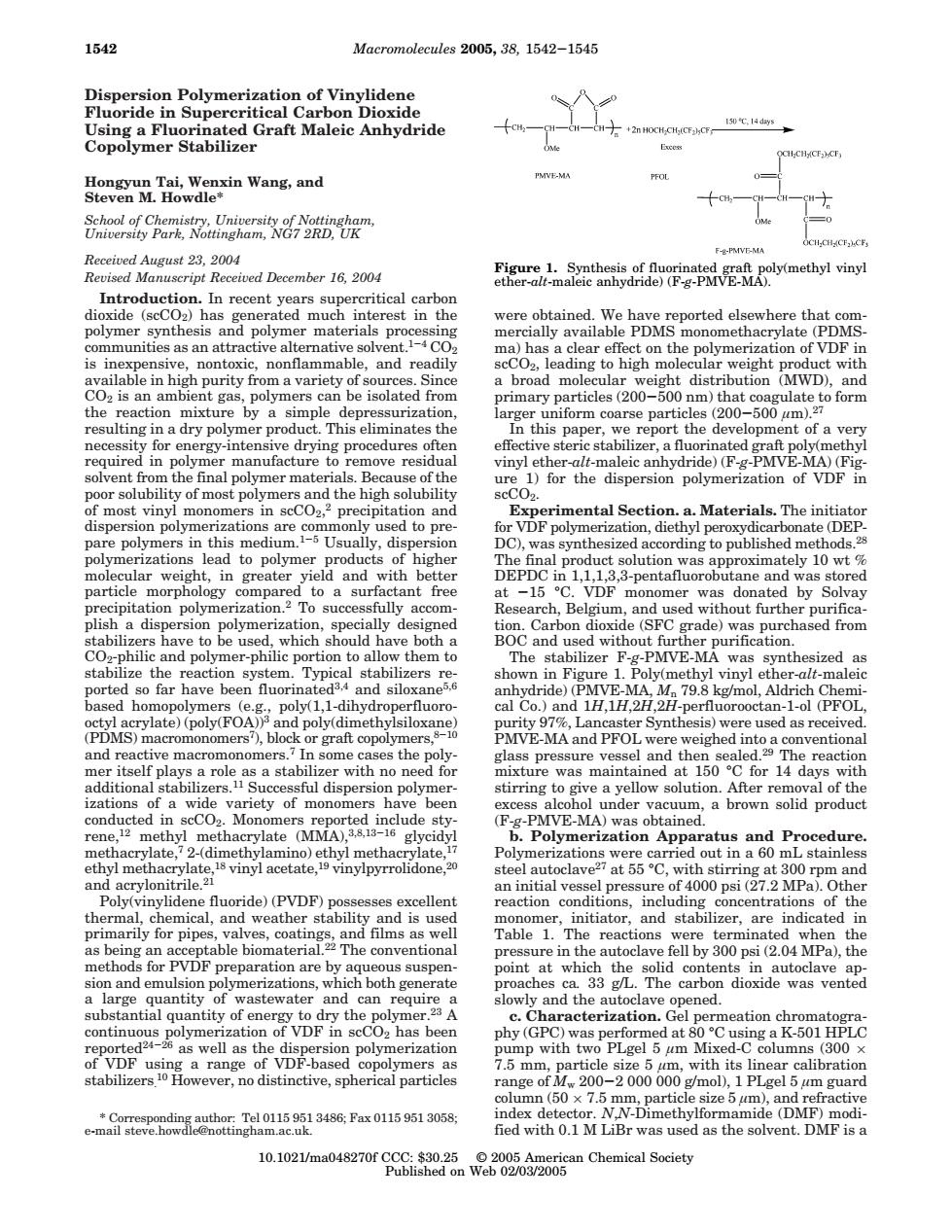

1542 Macromolecules 2005,38,1542-1545 Anhydride [CH stvn Wang.and MVE-M o Cpersr edDecember 16,2004 rest in the mereohtineiaWetpR5eportednoeeaheethatnse as an attr ative sol t on t purity from and is an am oe isolate primary particles(00 this pape report the developm quired manufacture tor emov and the high solubilit for C).w ordingto published a weigh ticle e ne and wass thout furth which a and ave BOC and used without ave be nd silo ri)(V Poly(n 1H.1H22 kg/mol,Aldr esi ome c el and ther as a ve a solutio of the a brown solid methyl acrylate F-PMVE-MA nder cuum me gly rization Pol tus and Pr ste e fluoride)(PVDF) sses excellent val at and films as wel ate. fell b 300 psi(2.04 MPa),th 33 oon dioxide was vente y the q2 s well as the with two PLgel 5 m Mixed c column (300 0200_200o600 with its pLgel5 with 0.I M LiBr was used as the solvent.DMF is a Dispersion Polymerization of Vinylidene Fluoride in Supercritical Carbon Dioxide Using a Fluorinated Graft Maleic Anhydride Copolymer Stabilizer Hongyun Tai, Wenxin Wang, and Steven M. Howdle* School of Chemistry, University of Nottingham, University Park, Nottingham, NG7 2RD, UK Received August 23, 2004 Revised Manuscript Received December 16, 2004 Introduction. In recent years supercritical carbon dioxide (scCO2) has generated much interest in the polymer synthesis and polymer materials processing communities as an attractive alternative solvent.1-4 CO2 is inexpensive, nontoxic, nonflammable, and readily available in high purity from a variety of sources. Since CO2 is an ambient gas, polymers can be isolated from the reaction mixture by a simple depressurization, resulting in a dry polymer product. This eliminates the necessity for energy-intensive drying procedures often required in polymer manufacture to remove residual solvent from the final polymer materials. Because of the poor solubility of most polymers and the high solubility of most vinyl monomers in scCO2, 2 precipitation and dispersion polymerizations are commonly used to prepare polymers in this medium.1-5 Usually, dispersion polymerizations lead to polymer products of higher molecular weight, in greater yield and with better particle morphology compared to a surfactant free precipitation polymerization.2 To successfully accomplish a dispersion polymerization, specially designed stabilizers have to be used, which should have both a CO2-philic and polymer-philic portion to allow them to stabilize the reaction system. Typical stabilizers reported so far have been fluorinated3,4 and siloxane5,6 based homopolymers (e.g., poly(1,1-dihydroperfluorooctyl acrylate) (poly(FOA))3 and poly(dimethylsiloxane) (PDMS) macromonomers7), block or graft copolymers,8-10 and reactive macromonomers.7 In some cases the polymer itself plays a role as a stabilizer with no need for additional stabilizers.11 Successful dispersion polymerizations of a wide variety of monomers have been conducted in scCO2. Monomers reported include styrene,12 methyl methacrylate (MMA),3,8,13-16 glycidyl methacrylate,7 2-(dimethylamino) ethyl methacrylate,17 ethyl methacrylate,18 vinyl acetate,19 vinylpyrrolidone,20 and acrylonitrile.21 Poly(vinylidene fluoride) (PVDF) possesses excellent thermal, chemical, and weather stability and is used primarily for pipes, valves, coatings, and films as well as being an acceptable biomaterial.22 The conventional methods for PVDF preparation are by aqueous suspension and emulsion polymerizations, which both generate a large quantity of wastewater and can require a substantial quantity of energy to dry the polymer.23 A continuous polymerization of VDF in scCO2 has been reported24-26 as well as the dispersion polymerization of VDF using a range of VDF-based copolymers as stabilizers. 10 However, no distinctive, spherical particles were obtained. We have reported elsewhere that commercially available PDMS monomethacrylate (PDMSma) has a clear effect on the polymerization of VDF in scCO2, leading to high molecular weight product with a broad molecular weight distribution (MWD), and primary particles (200-500 nm) that coagulate to form larger uniform coarse particles (200-500 µm).27 In this paper, we report the development of a very effective steric stabilizer, a fluorinated graft poly(methyl vinyl ether-alt-maleic anhydride) (F-g-PMVE-MA) (Figure 1) for the dispersion polymerization of VDF in scCO2. Experimental Section. a. Materials. The initiator for VDF polymerization, diethyl peroxydicarbonate (DEPDC), was synthesized according to published methods.28 The final product solution was approximately 10 wt % DEPDC in 1,1,1,3,3-pentafluorobutane and was stored at -15 °C. VDF monomer was donated by Solvay Research, Belgium, and used without further purification. Carbon dioxide (SFC grade) was purchased from BOC and used without further purification. The stabilizer F-g-PMVE-MA was synthesized as shown in Figure 1. Poly(methyl vinyl ether-alt-maleic anhydride) (PMVE-MA, Mn 79.8 kg/mol, Aldrich Chemical Co.) and 1H,1H,2H,2H-perfluorooctan-1-ol (PFOL, purity 97%, Lancaster Synthesis) were used as received. PMVE-MA and PFOL were weighed into a conventional glass pressure vessel and then sealed.29 The reaction mixture was maintained at 150 °C for 14 days with stirring to give a yellow solution. After removal of the excess alcohol under vacuum, a brown solid product (F-g-PMVE-MA) was obtained. b. Polymerization Apparatus and Procedure. Polymerizations were carried out in a 60 mL stainless steel autoclave27 at 55 °C, with stirring at 300 rpm and an initial vessel pressure of 4000 psi (27.2 MPa). Other reaction conditions, including concentrations of the monomer, initiator, and stabilizer, are indicated in Table 1. The reactions were terminated when the pressure in the autoclave fell by 300 psi (2.04 MPa), the point at which the solid contents in autoclave approaches ca. 33 g/L. The carbon dioxide was vented slowly and the autoclave opened. c. Characterization. Gel permeation chromatography (GPC) was performed at 80 °C using a K-501 HPLC pump with two PLgel 5 µm Mixed-C columns (300 × 7.5 mm, particle size 5 µm, with its linear calibration range of Mw 200-2 000 000 g/mol), 1 PLgel 5 µm guard column (50 × 7.5 mm, particle size 5 µm), and refractive index detector. N,N-Dimethylformamide (DMF) modified with 0.1 M LiBr was used as the solvent. DMF is a * Corresponding author: Tel 0115 951 3486; Fax 0115 951 3058; e-mail steve.howdle@nottingham.ac.uk. Figure 1. Synthesis of fluorinated graft poly(methyl vinyl ether-alt-maleic anhydride) (F-g-PMVE-MA). 1542 Macromolecules 2005, 38, 1542-1545 10.1021/ma048270f CCC: $30.25 © 2005 American Chemical Society Published on Web 02/03/2005