正在加载图片...

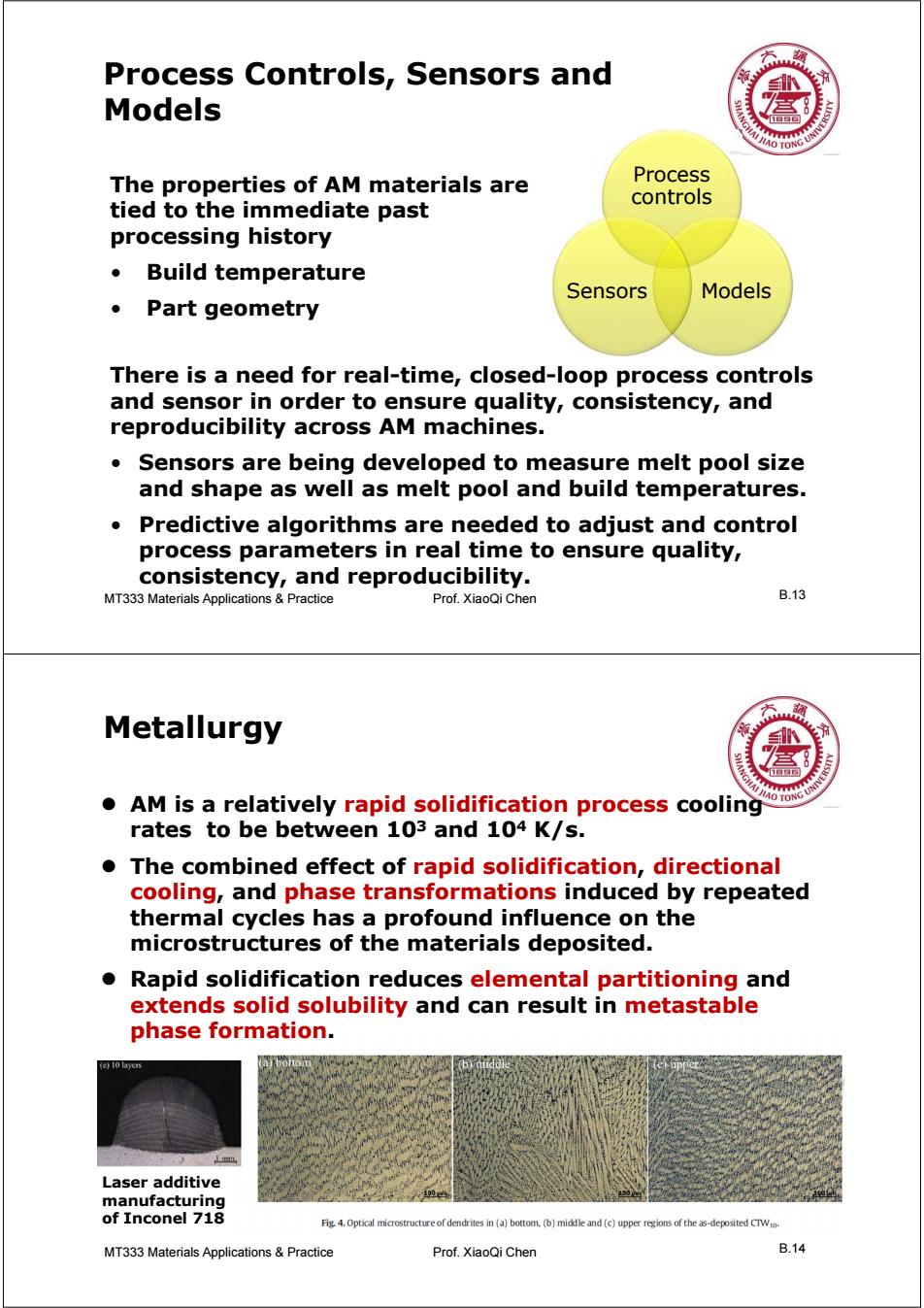

Process Controls,Sensors and Models 盒 The properties of AM materials are Process controls tied to the immediate past processing history 。 Build temperature Sensors Models ·Part geometry There is a need for real-time,closed-loop process controls and sensor in order to ensure quality,consistency,and reproducibility across AM machines. Sensors are being developed to measure melt pool size and shape as well as melt pool and build temperatures. Predictive algorithms are needed to adjust and control process parameters in real time to ensure quality, consistency,and reproducibility. MT333 Materials Applications Practice Prof.XiaoQi Chen B.13 Metallurgy AM is a relatively rapid solidification process cooling IO TONG rates to be between 103 and 104 K/s. ● The combined effect of rapid solidification,directional cooling,and phase transformations induced by repeated thermal cycles has a profound influence on the microstructures of the materials deposited. Rapid solidification reduces elemental partitioning and extends solid solubility and can result in metastable phase formation. (e)10 layen Laser additive manufacturing of Inconel 718 Fig4.Optical microstructureof dendrites in (a)bottom.(b)middle and (c)upper regions of the as-deposited CTW MT333 Materials Applications&Practice Prof.XiaoQi Chen B.14MT333 Materials Applications B.13 & Practice Prof. XiaoQi Chen Process controls Sensors Models Process Controls, Sensors and Models The properties of AM materials are tied to the immediate past processing history • Build temperature • Part geometry There is a need for real-time, closed-loop process controls and sensor in order to ensure quality, consistency, and reproducibility across AM machines. • Sensors are being developed to measure melt pool size and shape as well as melt pool and build temperatures. • Predictive algorithms are needed to adjust and control process parameters in real time to ensure quality, consistency, and reproducibility. MT333 Materials Applications B.14 & Practice Prof. XiaoQi Chen Laser additive manufacturing of Inconel 718 Metallurgy AM is a relatively rapid solidification process cooling rates to be between 103 and 104 K/s. The combined effect of rapid solidification, directional cooling, and phase transformations induced by repeated thermal cycles has a profound influence on the microstructures of the materials deposited. Rapid solidification reduces elemental partitioning and extends solid solubility and can result in metastable phase formation