正在加载图片...

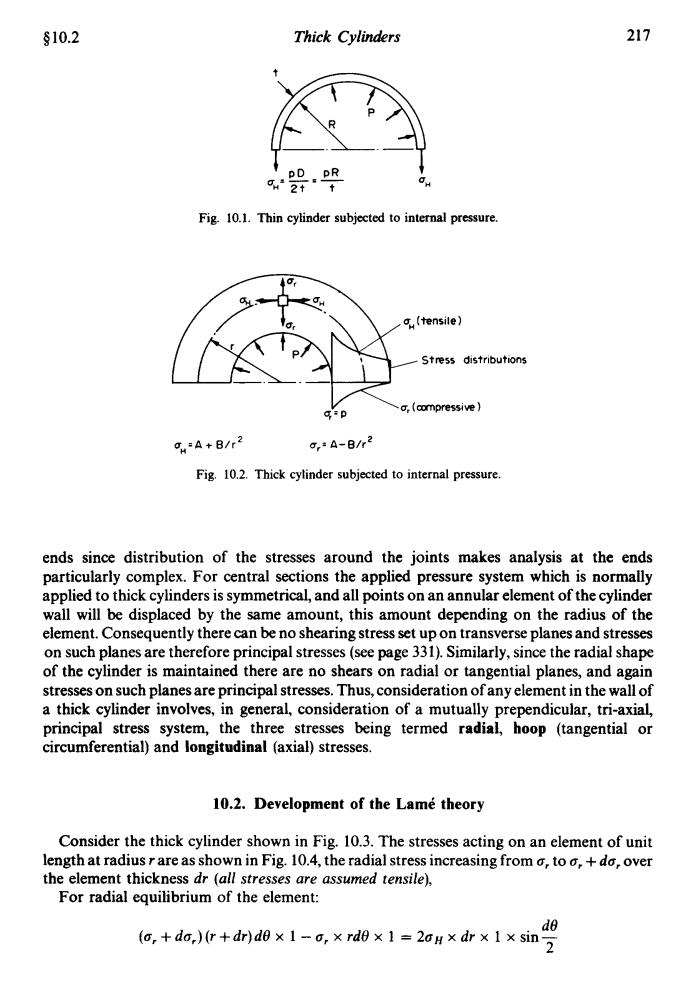

§10.2 Thick Cylinders 217 2t Fig.10.1.Thin cylinder subjected to internal pressure. c,(tensile】 Stress distributions a.(compressive c-p A+B/r2 ,A-B/r2 Fig.10.2.Thick cylinder subjected to internal pressure. ends since distribution of the stresses around the joints makes analysis at the ends particularly complex.For central sections the applied pressure system which is normally applied to thick cylinders is symmetrical,and all points on an annular element of the cylinder wall will be displaced by the same amount,this amount depending on the radius of the element.Consequently there can be no shearing stress set up on transverse planes and stresses on such planes are therefore principal stresses(see page 331).Similarly,since the radial shape of the cylinder is maintained there are no shears on radial or tangential planes,and again stresses on such planes are principal stresses.Thus,consideration of any element in the wall of a thick cylinder involves,in general,consideration of a mutually prependicular,tri-axial, principal stress system,the three stresses being termed radial,hoop (tangential or circumferential)and longitudinal (axial)stresses. 10.2.Development of the Lame theory Consider the thick cylinder shown in Fig.10.3.The stresses acting on an element of unit length at radius r are as shown in Fig.10.4,the radial stress increasing from a,to o,+do,over the element thickness dr (all stresses are assumed tensile), For radial equilibrium of the element: o,+do,)r+dn)d0x1-o,×rd6×1=2oH×dr×1×sin20 10.2 Thick Cylinders 217 Fig. 10.1. Thin cylinder subjected to internal pressure. Stress distributions uH=A + B/r2 u,= A-B/r2 Fig. 10.2. Thick cylinder subjected to internal pressure. ends since distribution of the stresses around the joints makes analysis at the ends particularly complex. For central sections the applied pressure system which is normally applied to thick cylinders is symmetrical, and all points on an annular element of the cylinder wall will be displaced by the same amount, this amount depending on the radius of the element. Consequently there can be no shearing stress set up on transverse planes and stresses on such planes are therefore principal stresses (see page 331). Similarly, since the radial shape of the cylinder is maintained there are no shears on radial or tangential planes, and again stresses on such planes are principal stresses. Thus, consideration of any element in the wall of a thick cylinder involves, in general, consideration of a mutually prependicular, tri-axial, principal stress system, the three stresses being termed radial, hoop (tangential or circumferential) and longitudinal (axial) stresses. 10.2. Development of the Lam6 theory Consider the thick cylinder shown in Fig. 10.3. The stresses acting on an element of unit length at radius rare as shown in Fig. 10.4, the radial stress increasing from a, to a, + da, over the element thickness dr (all stresses are assumed tensile), For radial equilibrium of the element: de (a,+da,)(r+dr)de x 1-6, x rd0 x 1 = 2aH x dr x 1 x sin- 2