正在加载图片...

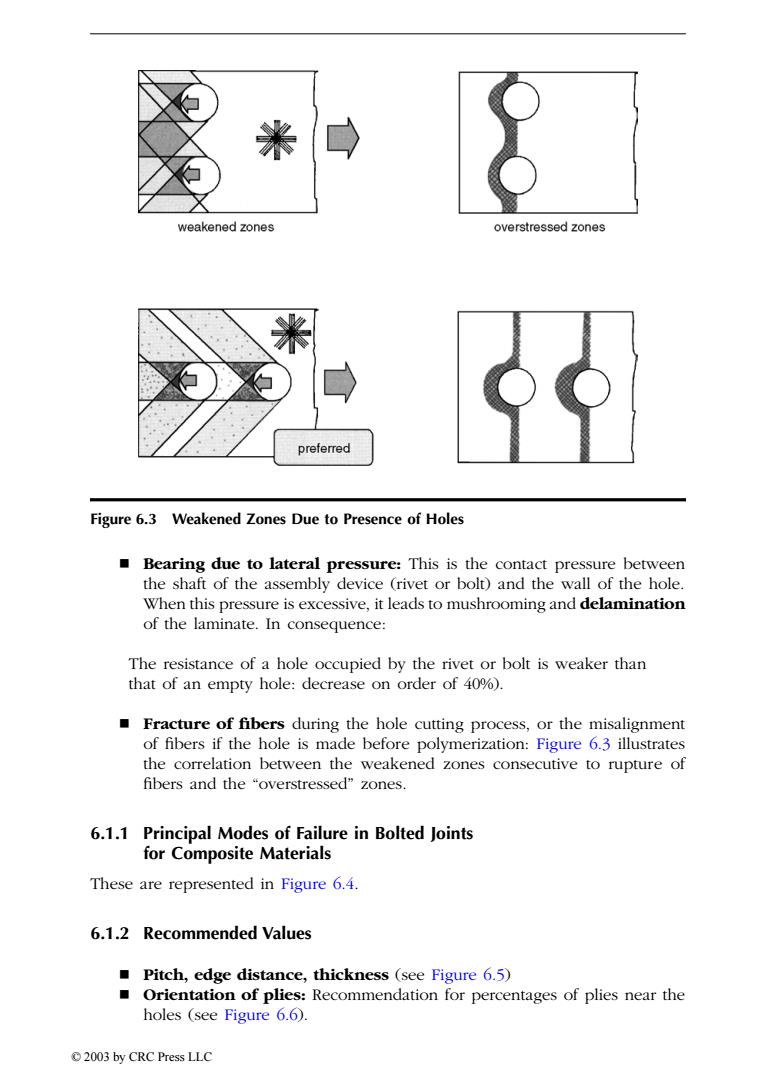

米 weakened zones overstressed zones preferred Figure 6.3 Weakened Zones Due to Presence of Holes Bearing due to lateral pressure:This is the contact pressure between the shaft of the assembly device (rivet or bolt)and the wall of the hole. When this pressure is excessive,it leads to mushrooming and delamination of the laminate.In consequence: The resistance of a hole occupied by the rivet or bolt is weaker than that of an empty hole:decrease on order of 40%). Fracture of fibers during the hole cutting process,or the misalignment of fibers if the hole is made before polymerization:Figure 6.3 illustrates the correlation between the weakened zones consecutive to rupture of fibers and the "overstressed"zones. 6.1.1 Principal Modes of Failure in Bolted Joints for Composite Materials These are represented in Figure 6.4. 6.1.2 Recommended Values Pitch,edge distance,thickness (see Figure 6.5) Orientation of plies:Recommendation for percentages of plies near the holes (see Figure 6.6). 2003 by CRC Press LLC Bearing due to lateral pressure: This is the contact pressure between the shaft of the assembly device (rivet or bolt) and the wall of the hole. When this pressure is excessive, it leads to mushrooming and delamination of the laminate. In consequence: The resistance of a hole occupied by the rivet or bolt is weaker than that of an empty hole: decrease on order of 40%). Fracture of fibers during the hole cutting process, or the misalignment of fibers if the hole is made before polymerization: Figure 6.3 illustrates the correlation between the weakened zones consecutive to rupture of fibers and the “overstressed” zones. 6.1.1 Principal Modes of Failure in Bolted Joints for Composite Materials These are represented in Figure 6.4. 6.1.2 Recommended Values Pitch, edge distance, thickness (see Figure 6.5) Orientation of plies: Recommendation for percentages of plies near the holes (see Figure 6.6). Figure 6.3 Weakened Zones Due to Presence of Holes © 2003 by CRC Press LLC