正在加载图片...

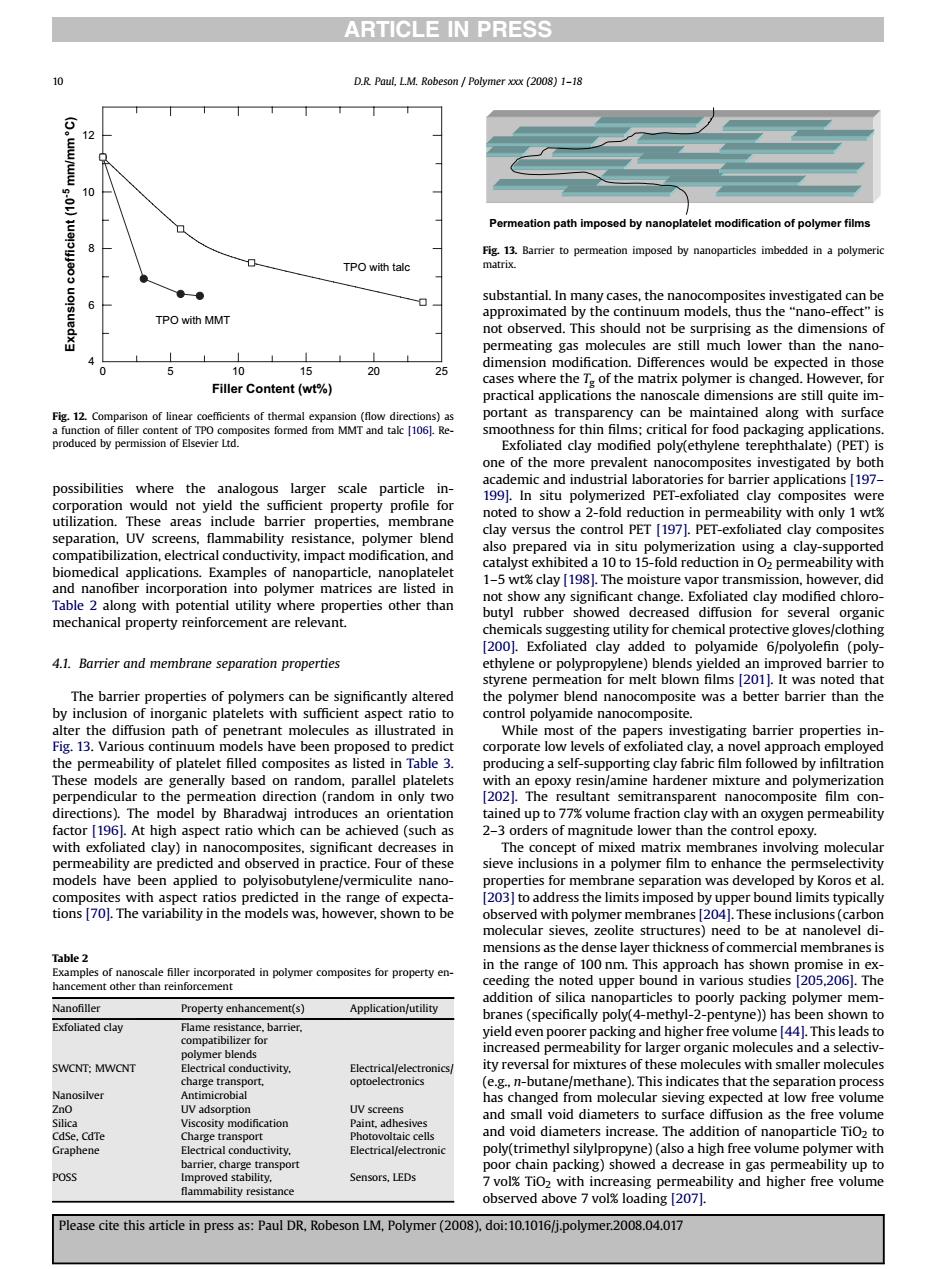

ARTICLE IN PRESS 10 DR Poul,LM.Robes /Polymer (200)1-1 60 Permeation path imposed by na ation of polymer film TPO with talo TPO with MM Filler Content(wt%) food packaging application 19 situ poly oesotaopatae ation.and also sted 5 wt cay The moisture mechanical property reinforcement are relevant 4.1.Barrier and membrane separation properties 一 te was a better barrier than the gehcCdiusionpatho pen ules as /hile t filled composit 2 d by infiltratio e 办At high nodels have ben appied vermiculite nano tions 7 The variability in the models was,however.shown to be 2041.T ions(c mensions as th s of commercial membranes is able 2 in pol en Application/utility WCNT:MWCNI ged and oid dian ers increase The addition of nanopartide Electrical/electron in gas Sensors.LEDs igher free volume Please cite this article in press as:Paul DR,Robeson LM,Polymer(2008).doi:10.1016/j.polymer.2008.04.017possibilities where the analogous larger scale particle incorporation would not yield the sufficient property profile for utilization. These areas include barrier properties, membrane separation, UV screens, flammability resistance, polymer blend compatibilization, electrical conductivity, impact modification, and biomedical applications. Examples of nanoparticle, nanoplatelet and nanofiber incorporation into polymer matrices are listed in Table 2 along with potential utility where properties other than mechanical property reinforcement are relevant. 4.1. Barrier and membrane separation properties The barrier properties of polymers can be significantly altered by inclusion of inorganic platelets with sufficient aspect ratio to alter the diffusion path of penetrant molecules as illustrated in Fig. 13. Various continuum models have been proposed to predict the permeability of platelet filled composites as listed in Table 3. These models are generally based on random, parallel platelets perpendicular to the permeation direction (random in only two directions). The model by Bharadwaj introduces an orientation factor [196]. At high aspect ratio which can be achieved (such as with exfoliated clay) in nanocomposites, significant decreases in permeability are predicted and observed in practice. Four of these models have been applied to polyisobutylene/vermiculite nanocomposites with aspect ratios predicted in the range of expectations [70]. The variability in the models was, however, shown to be substantial. In many cases, the nanocomposites investigated can be approximated by the continuum models, thus the ‘‘nano-effect’’ is not observed. This should not be surprising as the dimensions of permeating gas molecules are still much lower than the nanodimension modification. Differences would be expected in those cases where the Tg of the matrix polymer is changed. However, for practical applications the nanoscale dimensions are still quite important as transparency can be maintained along with surface smoothness for thin films; critical for food packaging applications. Exfoliated clay modified poly(ethylene terephthalate) (PET) is one of the more prevalent nanocomposites investigated by both academic and industrial laboratories for barrier applications [197– 199]. In situ polymerized PET-exfoliated clay composites were noted to show a 2-fold reduction in permeability with only 1 wt% clay versus the control PET [197]. PET-exfoliated clay composites also prepared via in situ polymerization using a clay-supported catalyst exhibited a 10 to 15-fold reduction in O2 permeability with 1–5 wt% clay [198]. The moisture vapor transmission, however, did not show any significant change. Exfoliated clay modified chlorobutyl rubber showed decreased diffusion for several organic chemicals suggesting utility for chemical protective gloves/clothing [200]. Exfoliated clay added to polyamide 6/polyolefin (polyethylene or polypropylene) blends yielded an improved barrier to styrene permeation for melt blown films [201]. It was noted that the polymer blend nanocomposite was a better barrier than the control polyamide nanocomposite. While most of the papers investigating barrier properties incorporate low levels of exfoliated clay, a novel approach employed producing a self-supporting clay fabric film followed by infiltration with an epoxy resin/amine hardener mixture and polymerization [202]. The resultant semitransparent nanocomposite film contained up to 77% volume fraction clay with an oxygen permeability 2–3 orders of magnitude lower than the control epoxy. The concept of mixed matrix membranes involving molecular sieve inclusions in a polymer film to enhance the permselectivity properties for membrane separation was developed by Koros et al. [203] to address the limits imposed by upper bound limits typically observed with polymer membranes [204]. These inclusions (carbon molecular sieves, zeolite structures) need to be at nanolevel dimensions as the dense layer thickness of commercial membranes is in the range of 100 nm. This approach has shown promise in exceeding the noted upper bound in various studies [205,206]. The addition of silica nanoparticles to poorly packing polymer membranes (specifically poly(4-methyl-2-pentyne)) has been shown to yield even poorer packing and higher free volume [44]. This leads to increased permeability for larger organic molecules and a selectivity reversal for mixtures of these molecules with smaller molecules (e.g., n-butane/methane). This indicates that the separation process has changed from molecular sieving expected at low free volume and small void diameters to surface diffusion as the free volume and void diameters increase. The addition of nanoparticle TiO2 to poly(trimethyl silylpropyne) (also a high free volume polymer with poor chain packing) showed a decrease in gas permeability up to 7 vol% TiO2 with increasing permeability and higher free volume observed above 7 vol% loading [207]. Filler Content (wt%) 0 5 10 15 20 25 Expansion coefficient (10-5 mm/mm °C) 4 6 8 10 12 TPO with MMT TPO with talc Fig. 12. Comparison of linear coefficients of thermal expansion (flow directions) as a function of filler content of TPO composites formed from MMT and talc [106]. Reproduced by permission of Elsevier Ltd. Table 2 Examples of nanoscale filler incorporated in polymer composites for property enhancement other than reinforcement Nanofiller Property enhancement(s) Application/utility Exfoliated clay Flame resistance, barrier, compatibilizer for polymer blends SWCNT; MWCNT Electrical conductivity, charge transport, Electrical/electronics/ optoelectronics Nanosilver Antimicrobial ZnO UV adsorption UV screens Silica Viscosity modification Paint, adhesives CdSe, CdTe Charge transport Photovoltaic cells Graphene Electrical conductivity, barrier, charge transport Electrical/electronic POSS Improved stability, flammability resistance Sensors, LEDs Permeation path imposed by nanoplatelet modification of polymer films Fig. 13. Barrier to permeation imposed by nanoparticles imbedded in a polymeric matrix. 10 D.R. Paul, L.M. Robeson / Polymer xxx (2008) 1–18 ARTICLE IN PRESS Please cite this article in press as: Paul DR, Robeson LM, Polymer (2008), doi:10.1016/j.polymer.2008.04.017