正在加载图片...

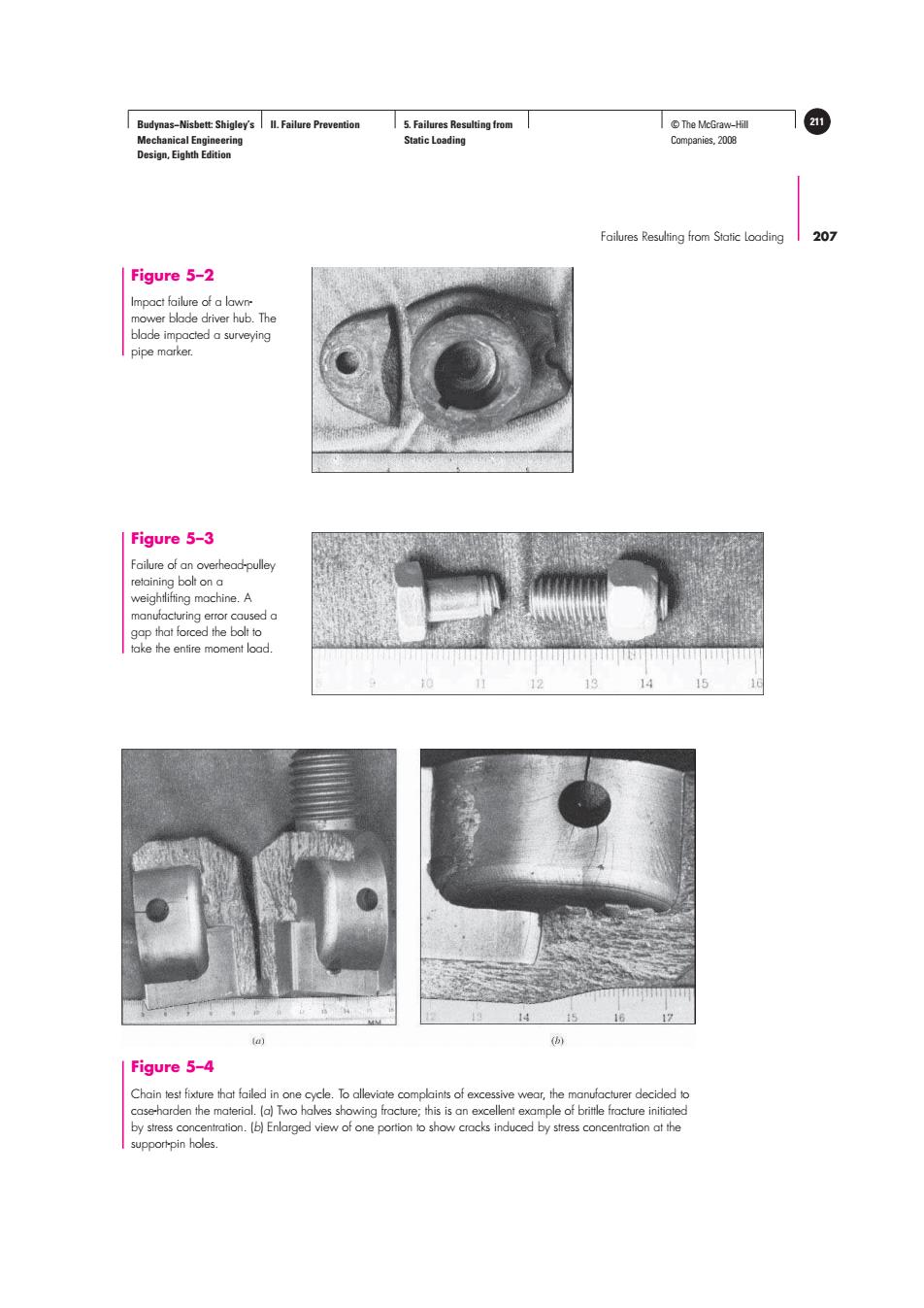

Budynas-Nisbett:Shigley's ll.Failure Prevention 5.Failures Resulting from ©The McGraw-Hil 21 Mechanical Engineering Static Loading Companies,2008 Design,Eighth Edition Failures Resulting from Static Loading 207 Figure 5-2 Impact failure of a lawn mower blade driver hub.The blade impacted a surveying pipe marker. Figure 5-3 Failure of an overhead-pulley retaining bolt on a weightlifting mochine.A manufacturing error caused a gap that forced the bolt to take the entire moment load. (a) (b) Figure 5-4 Chain test fixture that failed in one cycle.To alleviate complaints of excessive wear,the manufacturer decided to case-harden the material.(a)Two halves showing fracture;this is an excellent example of brittle fracture initiated by stress concentration.(b)Enlarged view of one portion to show cracks induced by stress concentration at the support-pin holes.Budynas−Nisbett: Shigley’s Mechanical Engineering Design, Eighth Edition II. Failure Prevention 5. Failures Resulting from Static Loading © The McGraw−Hill 211 Companies, 2008 Figure 5–2 Impact failure of a lawnmower blade driver hub. The blade impacted a surveying pipe marker. Figure 5–3 Failure of an overhead-pulley retaining bolt on a weightlifting machine. A manufacturing error caused a gap that forced the bolt to take the entire moment load. Figure 5–4 Chain test fixture that failed in one cycle. To alleviate complaints of excessive wear, the manufacturer decided to case-harden the material. (a) Two halves showing fracture; this is an excellent example of brittle fracture initiated by stress concentration. (b) Enlarged view of one portion to show cracks induced by stress concentration at the support-pin holes. Failures Resulting from Static Loading 207