正在加载图片...

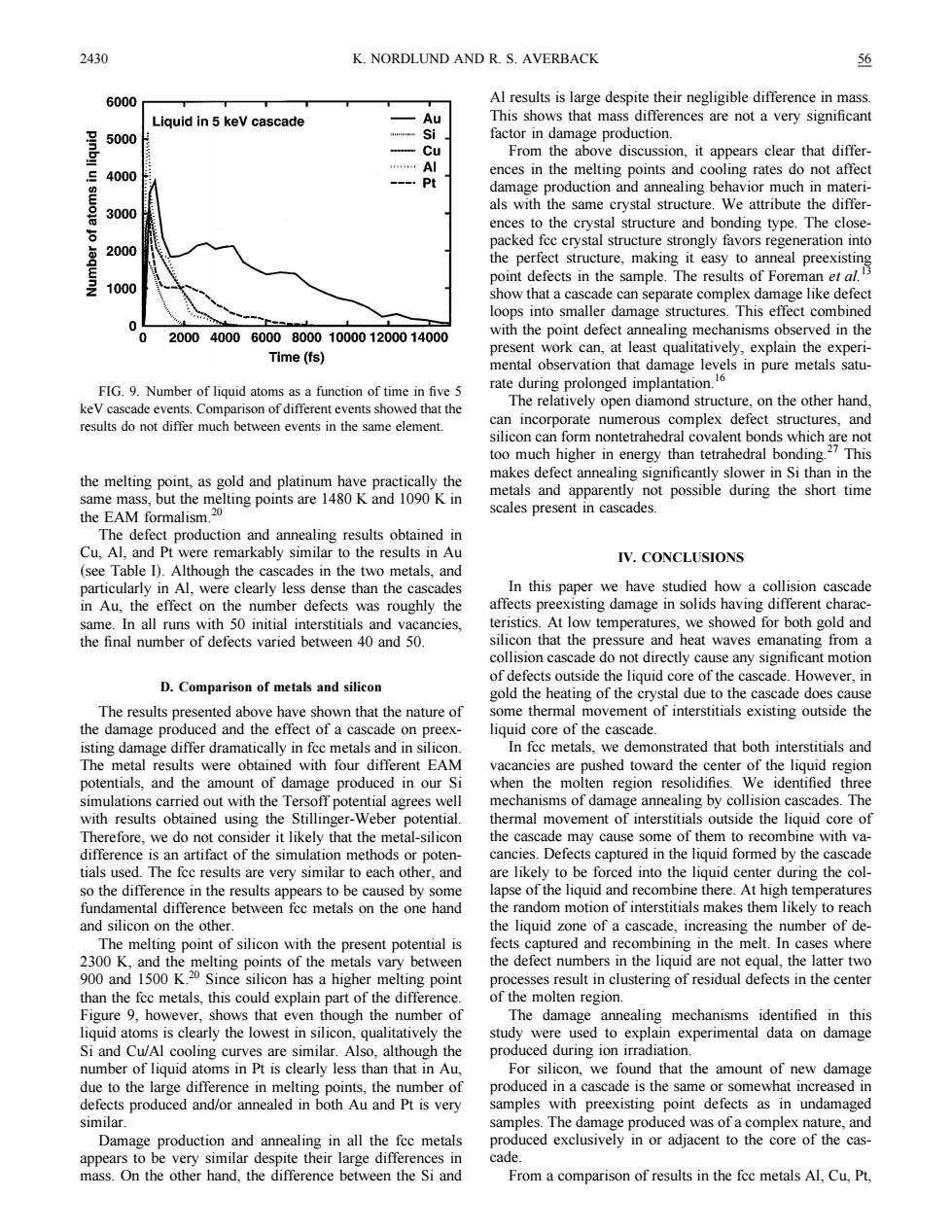

2430 K.NORDLUND AND R.S.AVERBACK 56 6000 Al results is large despite their negligible difference in mass. Liquid in 5 keV cascade Au This shows that mass differences are not a very significant 号 5000 Si factor in damage production. Cu From the above discussion,it appears clear that differ- Al 4000 ences in the melting points and cooling rates do not affect Pt damage production and annealing behavior much in materi- 3000 als with the same crystal structure.We attribute the differ- ences to the crystal structure and bonding type.The close- packed fcc crystal structure strongly favors regeneration into 2000 the perfect structure,making it easy to anneal preexisting wnN 1000 point defects in the sample.The results of Foreman show that a cascade can separate complex damage like defect loops into smaller damage structures.This effect combined 2000400060008000100001200014000 with the point defect annealing mechanisms observed in the Time (fs) present work can,at least qualitatively,explain the experi- mental observation that damage levels in pure metals satu- FIG.9.Number of liquid atoms as a function of time in five 5 rate during prolonged implantation.6 keV cascade events.Comparison of different events showed that the The relatively open diamond structure,on the other hand. results do not differ much between events in the same element. can incorporate numerous complex defect structures,and silicon can form nontetrahedral covalent bonds which are not too much higher in energy than tetrahedral bonding.27 This makes defect annealing significantly slower in Si than in the the melting point,as gold and platinum have practically the same mass,but the melting points are 1480 K and 1090 K in metals and apparently not possible during the short time the EAM formalism.20 scales present in cascades. The defect production and annealing results obtained in Cu,Al,and Pt were remarkably similar to the results in Au IV.CONCLUSIONS (see Table I).Although the cascades in the two metals,and particularly in Al,were clearly less dense than the cascades In this paper we have studied how a collision cascade in Au,the effect on the number defects was roughly the affects preexisting damage in solids having different charac- same.In all runs with 50 initial interstitials and vacancies, teristics.At low temperatures,we showed for both gold and the final number of defects varied between 40 and 50. silicon that the pressure and heat waves emanating from a collision cascade do not directly cause any significant motion of defects outside the liquid core of the cascade.However,in D.Comparison of metals and silicon gold the heating of the crystal due to the cascade does cause The results presented above have shown that the nature of some thermal movement of interstitials existing outside the the damage produced and the effect of a cascade on preex- liquid core of the cascade. isting damage differ dramatically in fcc metals and in silicon. In fec metals,we demonstrated that both interstitials and The metal results were obtained with four different EAM vacancies are pushed toward the center of the liquid region potentials,and the amount of damage produced in our Si when the molten region resolidifies.We identified three simulations carried out with the Tersoff potential agrees well mechanisms of damage annealing by collision cascades.The with results obtained using the Stillinger-Weber potential. thermal movement of interstitials outside the liquid core of Therefore,we do not consider it likely that the metal-silicon the cascade may cause some of them to recombine with va- difference is an artifact of the simulation methods or poten- cancies.Defects captured in the liquid formed by the cascade tials used.The fcc results are very similar to each other,and are likely to be forced into the liquid center during the col- so the difference in the results appears to be caused by some lapse of the liquid and recombine there.At high temperatures fundamental difference between fcc metals on the one hand the random motion of interstitials makes them likely to reach and silicon on the other. the liquid zone of a cascade,increasing the number of de- The melting point of silicon with the present potential is fects captured and recombining in the melt.In cases where 2300 K,and the melting points of the metals vary between the defect numbers in the liquid are not equal,the latter two 900 and 1500 K20 Since silicon has a higher melting point processes result in clustering of residual defects in the center than the fcc metals,this could explain part of the difference. of the molten region. Figure 9,however,shows that even though the number of The damage annealing mechanisms identified in this liquid atoms is clearly the lowest in silicon.qualitatively the study were used to explain experimental data on damage Si and Cu/Al cooling curves are similar.Also,although the produced during ion irradiation. number of liquid atoms in Pt is clearly less than that in Au, For silicon,we found that the amount of new damage due to the large difference in melting points,the number of produced in a cascade is the same or somewhat increased in defects produced and/or annealed in both Au and Pt is very samples with preexisting point defects as in undamaged similar. samples.The damage produced was of a complex nature,and Damage production and annealing in all the fcc metals produced exclusively in or adjacent to the core of the cas- appears to be very similar despite their large differences in cade mass.On the other hand.the difference between the Si and From a comparison of results in the fcc metals Al,Cu,Pt,the melting point, as gold and platinum have practically the same mass, but the melting points are 1480 K and 1090 K in the EAM formalism.20 The defect production and annealing results obtained in Cu, Al, and Pt were remarkably similar to the results in Au ~see Table I!. Although the cascades in the two metals, and particularly in Al, were clearly less dense than the cascades in Au, the effect on the number defects was roughly the same. In all runs with 50 initial interstitials and vacancies, the final number of defects varied between 40 and 50. D. Comparison of metals and silicon The results presented above have shown that the nature of the damage produced and the effect of a cascade on preexisting damage differ dramatically in fcc metals and in silicon. The metal results were obtained with four different EAM potentials, and the amount of damage produced in our Si simulations carried out with the Tersoff potential agrees well with results obtained using the Stillinger-Weber potential. Therefore, we do not consider it likely that the metal-silicon difference is an artifact of the simulation methods or potentials used. The fcc results are very similar to each other, and so the difference in the results appears to be caused by some fundamental difference between fcc metals on the one hand and silicon on the other. The melting point of silicon with the present potential is 2300 K, and the melting points of the metals vary between 900 and 1500 K.20 Since silicon has a higher melting point than the fcc metals, this could explain part of the difference. Figure 9, however, shows that even though the number of liquid atoms is clearly the lowest in silicon, qualitatively the Si and Cu/Al cooling curves are similar. Also, although the number of liquid atoms in Pt is clearly less than that in Au, due to the large difference in melting points, the number of defects produced and/or annealed in both Au and Pt is very similar. Damage production and annealing in all the fcc metals appears to be very similar despite their large differences in mass. On the other hand, the difference between the Si and Al results is large despite their negligible difference in mass. This shows that mass differences are not a very significant factor in damage production. From the above discussion, it appears clear that differences in the melting points and cooling rates do not affect damage production and annealing behavior much in materials with the same crystal structure. We attribute the differences to the crystal structure and bonding type. The closepacked fcc crystal structure strongly favors regeneration into the perfect structure, making it easy to anneal preexisting point defects in the sample. The results of Foreman et al.13 show that a cascade can separate complex damage like defect loops into smaller damage structures. This effect combined with the point defect annealing mechanisms observed in the present work can, at least qualitatively, explain the experimental observation that damage levels in pure metals saturate during prolonged implantation.16 The relatively open diamond structure, on the other hand, can incorporate numerous complex defect structures, and silicon can form nontetrahedral covalent bonds which are not too much higher in energy than tetrahedral bonding.27 This makes defect annealing significantly slower in Si than in the metals and apparently not possible during the short time scales present in cascades. IV. CONCLUSIONS In this paper we have studied how a collision cascade affects preexisting damage in solids having different characteristics. At low temperatures, we showed for both gold and silicon that the pressure and heat waves emanating from a collision cascade do not directly cause any significant motion of defects outside the liquid core of the cascade. However, in gold the heating of the crystal due to the cascade does cause some thermal movement of interstitials existing outside the liquid core of the cascade. In fcc metals, we demonstrated that both interstitials and vacancies are pushed toward the center of the liquid region when the molten region resolidifies. We identified three mechanisms of damage annealing by collision cascades. The thermal movement of interstitials outside the liquid core of the cascade may cause some of them to recombine with vacancies. Defects captured in the liquid formed by the cascade are likely to be forced into the liquid center during the collapse of the liquid and recombine there. At high temperatures the random motion of interstitials makes them likely to reach the liquid zone of a cascade, increasing the number of defects captured and recombining in the melt. In cases where the defect numbers in the liquid are not equal, the latter two processes result in clustering of residual defects in the center of the molten region. The damage annealing mechanisms identified in this study were used to explain experimental data on damage produced during ion irradiation. For silicon, we found that the amount of new damage produced in a cascade is the same or somewhat increased in samples with preexisting point defects as in undamaged samples. The damage produced was of a complex nature, and produced exclusively in or adjacent to the core of the cascade. From a comparison of results in the fcc metals Al, Cu, Pt, FIG. 9. Number of liquid atoms as a function of time in five 5 keV cascade events. Comparison of different events showed that the results do not differ much between events in the same element. 2430 K. NORDLUND AND R. S. AVERBACK 56