正在加载图片...

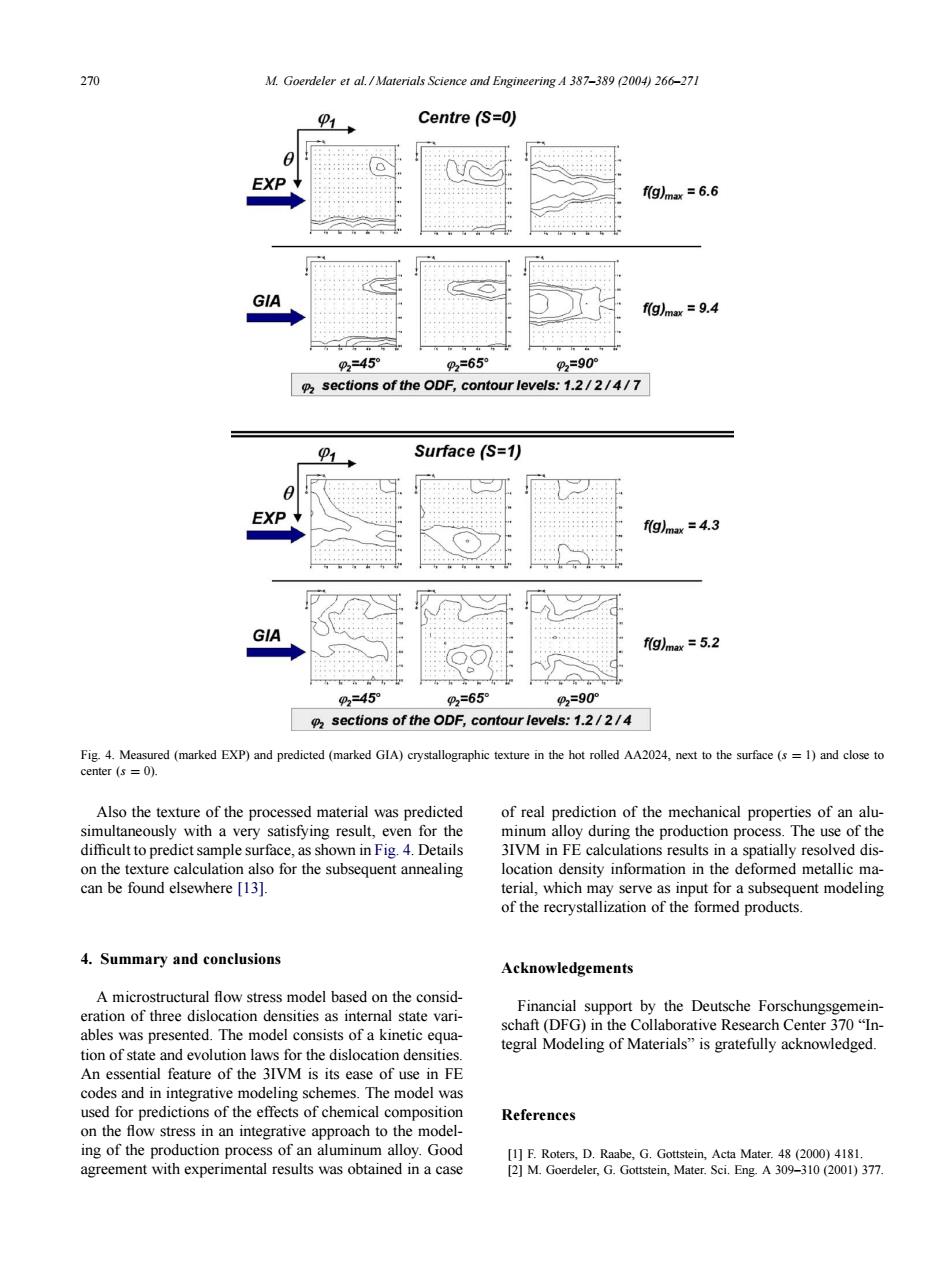

270 M.Goerdeler et al./Materials Science and Engineering A 387-389 (2004)266-271 P1 Centre (S=0) EXP f(g)max =6.6 GIA f(g)max =9.4 4 02=45 9=65 9=90 a sections of the ODF,contour levels:1.2/2/4/7 Surface (S=1) EXP f(g)max =4.3 GIA f(g)max =5.2 945 9=65 902=90° sections of the ODF,contour levels:1.2/2/4 Fig.4.Measured (marked EXP)and predicted(marked GIA)crystallographic texture in the hot rolled AA2024,next to the surface (s =1)and close to center (s =0). Also the texture of the processed material was predicted of real prediction of the mechanical properties of an alu- simultaneously with a very satisfying result,even for the minum alloy during the production process.The use of the difficult to predict sample surface,as shown in Fig.4.Details 31VM in FE calculations results in a spatially resolved dis- on the texture calculation also for the subsequent annealing location density information in the deformed metallic ma- can be found elsewhere [13]. terial,which may serve as input for a subsequent modeling of the recrystallization of the formed products. 4.Summary and conclusions Acknowledgements A microstructural flow stress model based on the consid- Financial support by the Deutsche Forschungsgemein- eration of three dislocation densities as internal state vari- ables was presented.The model consists of a kinetic equa- schaft(DFG)in the Collaborative Research Center 370"In- tion of state and evolution laws for the dislocation densities. tegral Modeling of Materials"is gratefully acknowledged. An essential feature of the 3IVM is its ease of use in FE codes and in integrative modeling schemes.The model was used for predictions of the effects of chemical composition References on the flow stress in an integrative approach to the model- ing of the production process of an aluminum alloy.Good [1]F.Roters,D.Raabe,G.Gottstein,Acta Mater.48(2000)4181 agreement with experimental results was obtained in a case [2]M.Goerdeler,G.Gottstein,Mater.Sci.Eng.A 309-310 (2001)377.270 M. Goerdeler et al. / Materials Science and Engineering A 387–389 (2004) 266–271 Fig. 4. Measured (marked EXP) and predicted (marked GIA) crystallographic texture in the hot rolled AA2024, next to the surface (s = 1) and close to center (s = 0). Also the texture of the processed material was predicted simultaneously with a very satisfying result, even for the difficult to predict sample surface, as shown in Fig. 4. Details on the texture calculation also for the subsequent annealing can be found elsewhere [13]. 4. Summary and conclusions A microstructural flow stress model based on the consideration of three dislocation densities as internal state variables was presented. The model consists of a kinetic equation of state and evolution laws for the dislocation densities. An essential feature of the 3IVM is its ease of use in FE codes and in integrative modeling schemes. The model was used for predictions of the effects of chemical composition on the flow stress in an integrative approach to the modeling of the production process of an aluminum alloy. Good agreement with experimental results was obtained in a case of real prediction of the mechanical properties of an aluminum alloy during the production process. The use of the 3IVM in FE calculations results in a spatially resolved dislocation density information in the deformed metallic material, which may serve as input for a subsequent modeling of the recrystallization of the formed products. Acknowledgements Financial support by the Deutsche Forschungsgemeinschaft (DFG) in the Collaborative Research Center 370 “Integral Modeling of Materials” is gratefully acknowledged. References [1] F. Roters, D. Raabe, G. Gottstein, Acta Mater. 48 (2000) 4181. [2] M. Goerdeler, G. Gottstein, Mater. Sci. Eng. A 309–310 (2001) 377