正在加载图片...

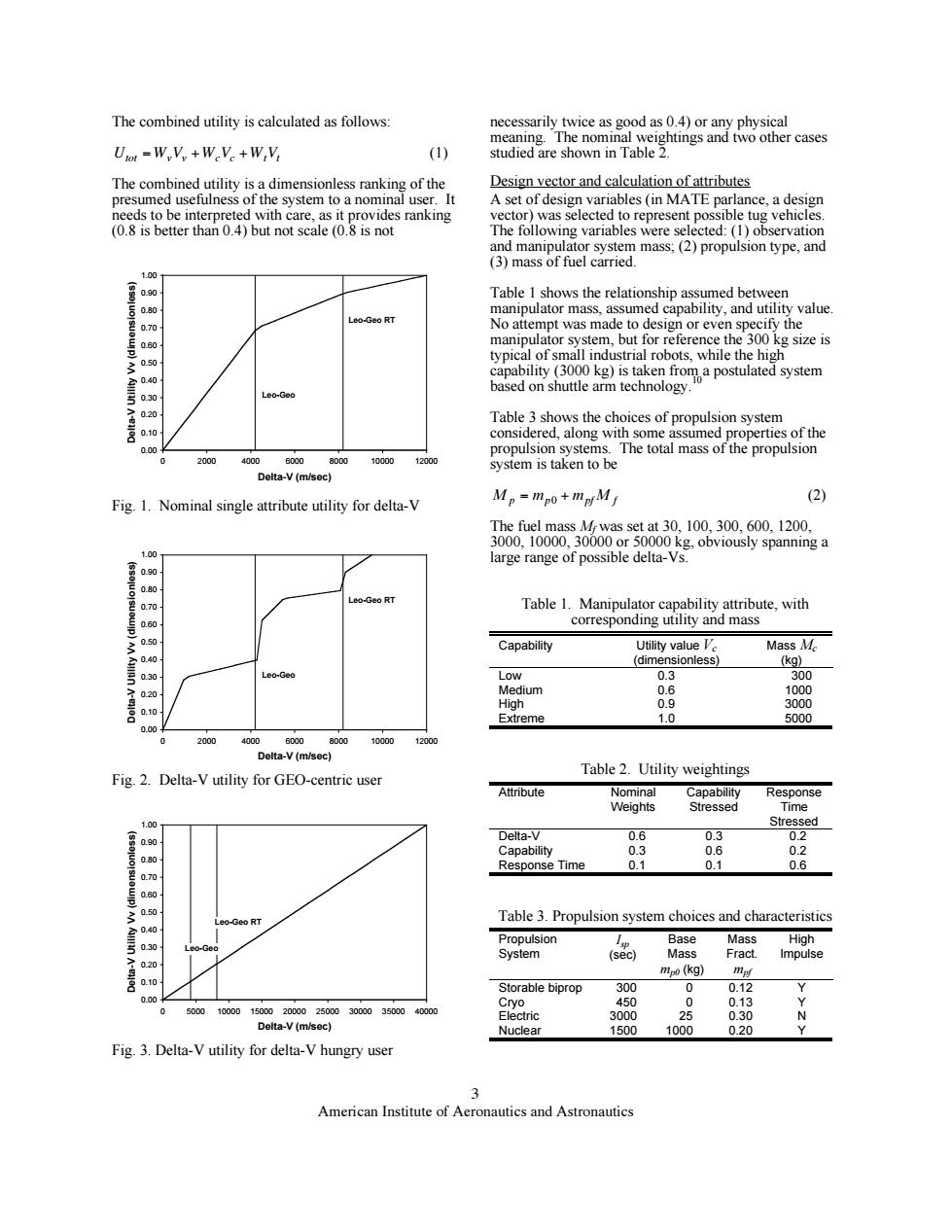

The combined utility is calculated as follows: necessarily twice as good as 0.4)or any physical meaning.The nominal weightings and two other cases Uio -W,V,+Weve +W,V (1) studied are shown in Table 2. The combined utility is a dimensionless ranking of the Design vector and calculation of attributes presumed usefulness of the system to a nominal user.It A set of design variables(in MATE parlance,a design needs to be interpreted with care,as it provides ranking vector)was selected to represent possible tug vehicles (0.8 is better than 0.4)but not scale(0.8 is not The following variables were selected:(1)observation and manipulator system mass;(2)propulsion type,and (3)mass of fuel carried. 1.00 0.90 Table 1 shows the relationship assumed between 080 manipulator mass,assumed capability,and utility value. a70 Leo-Geo RT No attempt was made to design or even specify the manipulator system,but for reference the 300 kg size is typical of small industrial robots,while the high 0.40 capability (3000 kg)is taken from a postulated system based on shuttle arm technology Leo-Geo 020 Table 3 shows the choices of propulsion system 010 considered,along with some assumed properties of the 0.00 propulsion systems.The total mass of the propulsion 2000 4000 6000 8000 10000 12000 system is taken to be Delta-V(m/sec) Fig.1.Nominal single attribute utility for delta-V Mp=mpo+mpyMj (2) The fuel mass M was set at 30,100,300,600,1200, 3000,10000,30000 or 50000 kg,obviously spanning a 1.00 large range of possible delta-Vs. 070 Leo-Geo RT Table 1.Manipulator capability attribute.with 0 corresponding utility and mass Capability Utility value Mass M. (dimensionless) (kg) Leo-Geo Low 0.3 300 Medium 0.6 1000 High 0.9 3000 Extreme 1.0 5000 0.00 0 2000 4000.6000 8000 10000 12000 Delta-V(m/sec) Table 2.Utility weightings Fig.2.Delta-V utility for GEO-centric user Attribute Nominal Capability Response Weights Stressed Time 1.00 Stressed 0.90 Delta-V 0.6 0.3 0.2 Capability 0.3 0.6 0.2 1 Response Time 0.1 0.1 0.6 050 0.40 -Geo RT Table 3.Propulsion system choices and characteristics 0.30 Propulsion Base Mass High System (sec) Mass Fract Impulse 020 mp0(kg) m时 0.10 Storable biprop 300 0 0.12 0.00 Cryo 450 0 0.13 0 500010000150002000025000300003500040000 Electric 3000 25 0.30 Delta-V(m/sec) Nuclear 1500 1000 0.20 Fig.3.Delta-V utility for delta-V hungry user 3 American Institute of Aeronautics and Astronautics3 American Institute of Aeronautics and Astronautics The combined utility is calculated as follows: † Utot = WvVv +WcVc +Wt Vt (1) The combined utility is a dimensionless ranking of the presumed usefulness of the system to a nominal user. It needs to be interpreted with care, as it provides ranking (0.8 is better than 0.4) but not scale (0.8 is not 0.00 0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80 0.90 1.00 0 2000 4000 6000 8000 10000 12000 Delta-V (m/sec) Delta-V Utility Vv (dimensionless) Leo-Geo Leo-Geo RT Fig. 1. Nominal single attribute utility for delta-V 0.00 0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80 0.90 1.00 0 2000 4000 6000 8000 10000 12000 Delta-V (m/sec) Delta-V Utility Vv (dimensionless) Leo-Geo Leo-Geo RT Fig. 2. Delta-V utility for GEO-centric user 0.00 0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80 0.90 1.00 0 5000 10000 15000 20000 25000 30000 35000 40000 Delta-V (m/sec) Delta-V Utility Vv (dimensionless) Leo-Geo Leo-Geo RT Fig. 3. Delta-V utility for delta-V hungry user necessarily twice as good as 0.4) or any physical meaning. The nominal weightings and two other cases studied are shown in Table 2. Design vector and calculation of attributes A set of design variables (in MATE parlance, a design vector) was selected to represent possible tug vehicles. The following variables were selected: (1) observation and manipulator system mass; (2) propulsion type, and (3) mass of fuel carried. Table 1 shows the relationship assumed between manipulator mass, assumed capability, and utility value. No attempt was made to design or even specify the manipulator system, but for reference the 300 kg size is typical of small industrial robots, while the high capability (3000 kg) is taken from a postulated system based on shuttle arm technology.10 Table 3 shows the choices of propulsion system considered, along with some assumed properties of the propulsion systems. The total mass of the propulsion system is taken to be † M p = mp0 + mpf M f (2) The fuel mass Mf was set at 30, 100, 300, 600, 1200, 3000, 10000, 30000 or 50000 kg, obviously spanning a large range of possible delta-Vs. Table 1. Manipulator capability attribute, with corresponding utility and mass Capability Utility value Vc (dimensionless) Mass Mc (kg) Low 0.3 300 Medium 0.6 1000 High 0.9 3000 Extreme 1.0 5000 Table 2. Utility weightings Attribute Nominal Weights Capability Stressed Response Time Stressed Delta-V 0.6 0.3 0.2 Capability 0.3 0.6 0.2 Response Time 0.1 0.1 0.6 Table 3. Propulsion system choices and characteristics Propulsion System Isp (sec) Base Mass mp0 (kg) Mass Fract. mpf High Impulse Storable biprop 300 0 0.12 Y Cryo 450 0 0.13 Y Electric 3000 25 0.30 N Nuclear 1500 1000 0.20 Y