正在加载图片...

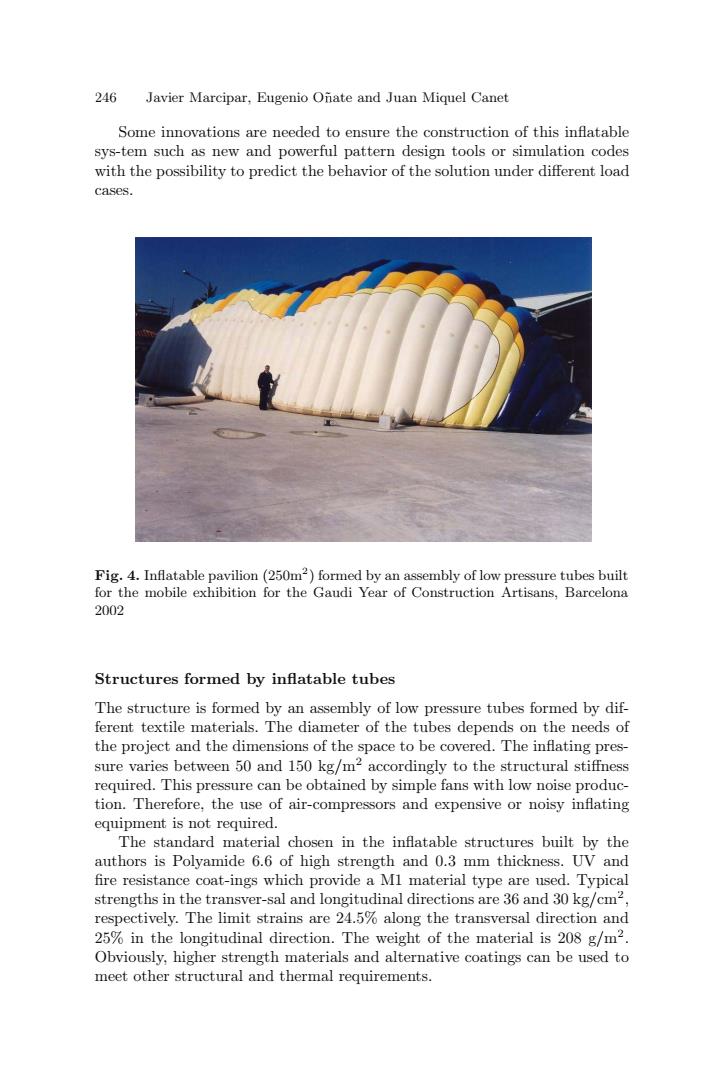

246 Javier Marcipar,Eugenio Onate and Juan Miquel Canet Some innovations are needed to ensure the construction of this inflatable sys-tem such as new and powerful pattern design tools or simulation codes with the possibility to predict the behavior of the solution under different load cases. Fig.4.Inflatable pavilion(250m2)formed by an assembly of low pressure tubes built for the mobile exhibition for the Gaudi Year of Construction Artisans,Barcelona 2002 Structures formed by inflatable tubes The structure is formed by an assembly of low pressure tubes formed by dif- ferent textile materials.The diameter of the tubes depends on the needs of the project and the dimensions of the space to be covered.The inflating pres- sure varies between 50 and 150 kg/m2 accordingly to the structural stiffness required.This pressure can be obtained by simple fans with low noise produc- tion.Therefore,the use of air-compressors and expensive or noisy inflating equipment is not required. The standard material chosen in the inflatable structures built by the authors is Polyamide 6.6 of high strength and 0.3 mm thickness.UV and fire resistance coat-ings which provide a M1 material type are used.Typical strengths in the transver-sal and longitudinal directions are 36 and 30 kg/cm2 respectively.The limit strains are 24.5%along the transversal direction and 25%in the longitudinal direction.The weight of the material is 208 g/m2. Obviously,higher strength materials and alternative coatings can be used to meet other structural and thermal requirements.246 Javier Marcipar, Eugenio O˜nate and Juan Miquel Canet ˜ Some innovations are needed to ensure the construction of this inflatable sys-tem such as new and powerful pattern design tools or simulation codes with the possibility to predict the behavior of the solution under different load cases. Fig. 4. Inflatable pavilion (250m2) formed by an assembly of low pressure tubes built for the mobile exhibition for the Gaudi Year of Construction Artisans, Barcelona 2002 Structures formed by inflatable tubes The structure is formed by an assembly of low pressure tubes formed by different textile materials. The diameter of the tubes depends on the needs of the project and the dimensions of the space to be covered. The inflating pressure varies between 50 and 150 kg/m2 accordingly to the structural stiffness required. This pressure can be obtained by simple fans with low noise production. Therefore, the use of air-compressors and expensive or noisy inflating equipment is not required. The standard material chosen in the inflatable structures built by the authors is Polyamide 6.6 of high strength and 0.3 mm thickness. UV and fire resistance coat-ings which provide a M1 material type are used. Typical strengths in the transver-sal and longitudinal directions are 36 and 30 kg/cm2, respectively. The limit strains are 24.5% along the transversal direction and 25% in the longitudinal direction. The weight of the material is 208 g/m2. Obviously, higher strength materials and alternative coatings can be used to meet other structural and thermal requirements