正在加载图片...

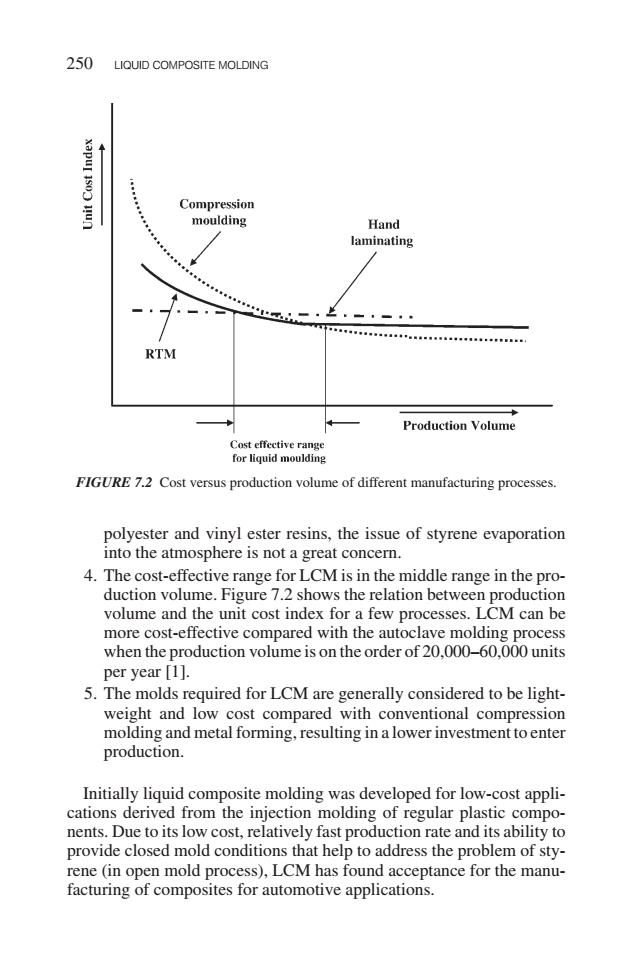

250 LIQUID COMPOSITE MOLDING : Compression moulding Hand laminating RTM Production Volume Cost effective range for liquid moulding FIGURE 7.2 Cost versus production volume of different manufacturing processes. polyester and vinyl ester resins,the issue of styrene evaporation into the atmosphere is not a great concern. 4.The cost-effective range for LCM is in the middle range in the pro- duction volume.Figure 7.2 shows the relation between production volume and the unit cost index for a few processes.LCM can be more cost-effective compared with the autoclave molding process when the production volume is on the order of 20,000-60,000 units per year [1]. 5.The molds required for LCM are generally considered to be light- weight and low cost compared with conventional compression molding and metal forming,resulting in a lower investment to enter production. Initially liquid composite molding was developed for low-cost appli- cations derived from the injection molding of regular plastic compo- nents.Due to its low cost,relatively fast production rate and its ability to provide closed mold conditions that help to address the problem of sty- rene (in open mold process),LCM has found acceptance for the manu- facturing of composites for automotive applications.polyester and vinyl ester resins, the issue of styrene evaporation into the atmosphere is not a great concern. 4. The cost-effective range for LCM is in the middle range in the production volume. Figure 7.2 shows the relation between production volume and the unit cost index for a few processes. LCM can be more cost-effective compared with the autoclave molding process when the production volume is on the order of 20,000–60,000 units per year [1]. 5. The molds required for LCM are generally considered to be lightweight and low cost compared with conventional compression molding and metal forming, resulting in a lower investment to enter production. Initially liquid composite molding was developed for low-cost applications derived from the injection molding of regular plastic components. Due to its low cost, relatively fast production rate and its ability to provide closed mold conditions that help to address the problem of styrene (in open mold process), LCM has found acceptance for the manufacturing of composites for automotive applications. 250 LIQUID COMPOSITE MOLDING FIGURE 7.2 Cost versus production volume of different manufacturing processes