正在加载图片...

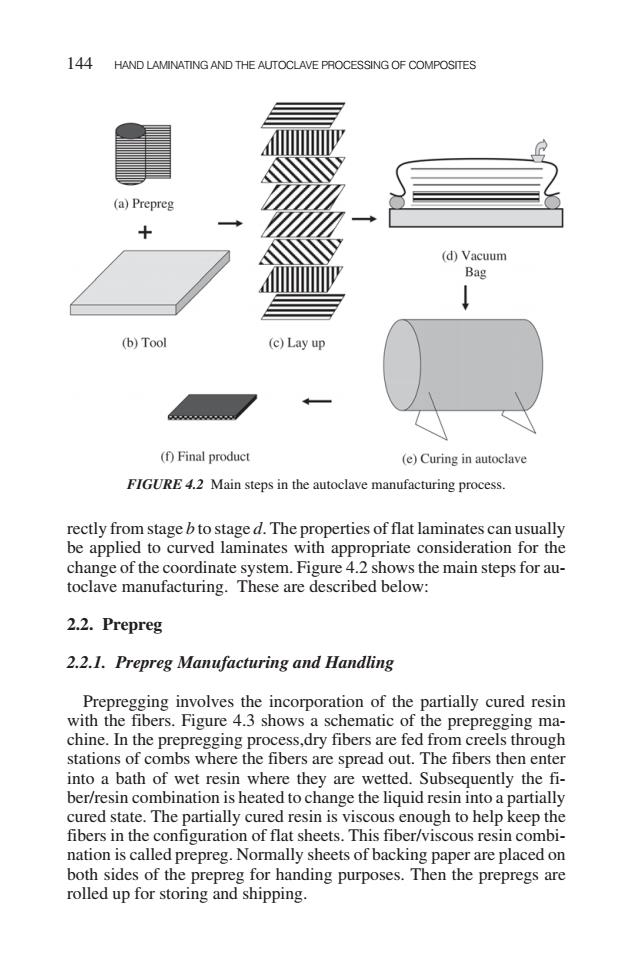

144 HAND LAMINATING AND THE AUTOCLAVE PROCESSING OF COMPOSITES (a)Prepreg (d)Vacuum Bag (b)Tool (c)Lay up ww8w8888 (f)Final product (e)Curing in autoclave FIGURE 4.2 Main steps in the autoclave manufacturing process. rectly from stage b to stage d.The properties of flat laminates can usually be applied to curved laminates with appropriate consideration for the change of the coordinate system.Figure 4.2 shows the main steps for au- toclave manufacturing.These are described below: 2.2.Prepreg 2.2.1.Prepreg Manufacturing and Handling Prepregging involves the incorporation of the partially cured resin with the fibers.Figure 4.3 shows a schematic of the prepregging ma- chine.In the prepregging process,dry fibers are fed from creels through stations of combs where the fibers are spread out.The fibers then enter into a bath of wet resin where they are wetted.Subsequently the fi- ber/resin combination is heated to change the liquid resin into a partially cured state.The partially cured resin is viscous enough to help keep the fibers in the configuration of flat sheets.This fiber/viscous resin combi- nation is called prepreg.Normally sheets of backing paper are placed on both sides of the prepreg for handing purposes.Then the prepregs are rolled up for storing and shipping.rectly from stage b to stage d. The properties of flat laminates can usually be applied to curved laminates with appropriate consideration for the change of the coordinate system. Figure 4.2 shows the main steps for autoclave manufacturing. These are described below: 2.2. Prepreg 2.2.1. Prepreg Manufacturing and Handling Prepregging involves the incorporation of the partially cured resin with the fibers. Figure 4.3 shows a schematic of the prepregging machine. In the prepregging process,dry fibers are fed from creels through stations of combs where the fibers are spread out. The fibers then enter into a bath of wet resin where they are wetted. Subsequently the fiber/resin combination is heated to change the liquid resin into a partially cured state. The partially cured resin is viscous enough to help keep the fibers in the configuration of flat sheets. This fiber/viscous resin combination is called prepreg. Normally sheets of backing paper are placed on both sides of the prepreg for handing purposes. Then the prepregs are rolled up for storing and shipping. 144 HAND LAMINATING AND THE AUTOCLAVE PROCESSING OF COMPOSITES FIGURE 4.2 Main steps in the autoclave manufacturing process