正在加载图片...

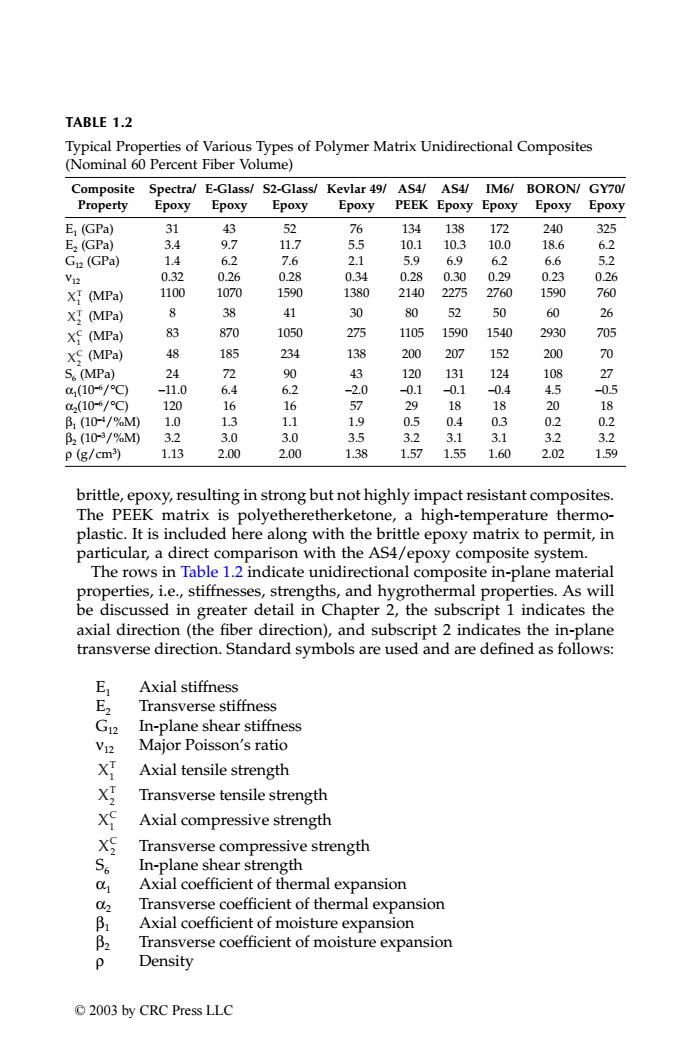

TABLE 1.2 Typical Properties of Various Types of Polymer Matrix Unidirectional Composites (Nominal 60 Percent Fiber Volume) Composite Spectra/E-Glass/S2-Glass/Kevlar 49/AS4/ AS4/IM6/ BORON/GY70/ Property Epoxy Epoxy Epoxy Epoxy PEEK Epoxy Epoxy Epoxy Epoxy E(GPa) 31 43 52 76 134 138 172 240 325 E2(GPa) 3.4 9.7 11.7 5.5 10.1 10.3 10.0 18.6 6.2 G2(GPa) 1.4 6.2 7.6 2.1 5.9 6.9 6.2 6.6 5.2 V12 0.32 0.26 0.28 0.34 0.28 0.30 0.29 0.23 0.26 X1 (MPa) 1100 1070 1590 1380 2140 2275 2760 1590 760 X (MPa) 8 38 41 30 80 52 50 60 26 Xf (MPa) 83 870 1050 275 1105 1590 1540 2930 705 Xf (MPa) 48 185 234 138 200 207 152 200 70 S(MPa) 24 72 90 43 120 131 124 108 27 a(10-6/C) -11.0 6.4 6.2 -2.0 -0.1 -0.1 -0.4 4.5 -0.5 2(10-6/C) 120 16 16 57 29 18 18 20 18 B(10-/%M0 1.0 1.3 1.1 1.9 0.5 0.4 0.3 0.2 0.2 β2(10/%M0 3.2 3.0 3.0 3.5 3.2 3.1 3.1 3.2 3.2 p (g/cm) 1.13 2.00 2.00 1.38 157 1.55 1.60 2.02 1.59 brittle,epoxy,resulting in strong but not highly impact resistant composites. The PEEK matrix is polyetheretherketone,a high-temperature thermo- plastic.It is included here along with the brittle epoxy matrix to permit,in particular,a direct comparison with the AS4/epoxy composite system. The rows in Table 1.2 indicate unidirectional composite in-plane material properties,ie.,stiffnesses,strengths,and hygrothermal properties.As will be discussed in greater detail in Chapter 2,the subscript 1 indicates the axial direction (the fiber direction),and subscript 2 indicates the in-plane transverse direction.Standard symbols are used and are defined as follows: E Axial stiffness Transverse stiffness G12 In-plane shear stiffness V12 Major Poisson's ratio X灯 Axial tensile strength X Transverse tensile strength Xe Axial compressive strength X Transverse compressive strength S6 In-plane shear strength 1 Axial coefficient of thermal expansion 02 Transverse coefficient of thermal expansion B Axial coefficient of moisture expansion β2 Transverse coefficient of moisture expansion 0 Density ©2003 by CRC Press LLCbrittle, epoxy, resulting in strong but not highly impact resistant composites. The PEEK matrix is polyetheretherketone, a high-temperature thermoplastic. It is included here along with the brittle epoxy matrix to permit, in particular, a direct comparison with the AS4/epoxy composite system. The rows in Table 1.2 indicate unidirectional composite in-plane material properties, i.e., stiffnesses, strengths, and hygrothermal properties. As will be discussed in greater detail in Chapter 2, the subscript 1 indicates the axial direction (the fiber direction), and subscript 2 indicates the in-plane transverse direction. Standard symbols are used and are defined as follows: E1 Axial stiffness E2 Transverse stiffness G12 In-plane shear stiffness ν12 Major Poisson’s ratio Axial tensile strength Transverse tensile strength Axial compressive strength Transverse compressive strength S6 In-plane shear strength α1 Axial coefficient of thermal expansion α2 Transverse coefficient of thermal expansion β1 Axial coefficient of moisture expansion β2 Transverse coefficient of moisture expansion ρ Density TABLE 1.2 Typical Properties of Various Types of Polymer Matrix Unidirectional Composites (Nominal 60 Percent Fiber Volume) Composite Property Spectra/ Epoxy E-Glass/ Epoxy S2-Glass/ Epoxy Kevlar 49/ Epoxy AS4/ PEEK AS4/ Epoxy IM6/ Epoxy BORON/ Epoxy GY70/ Epoxy E1 (GPa) 31 43 52 76 134 138 172 240 325 E2 (GPa) 3.4 9.7 11.7 5.5 10.1 10.3 10.0 18.6 6.2 G12 (GPa) 1.4 6.2 7.6 2.1 5.9 6.9 6.2 6.6 5.2 ν12 0.32 0.26 0.28 0.34 0.28 0.30 0.29 0.23 0.26 (MPa) 1100 1070 1590 1380 2140 2275 2760 1590 760 (MPa) 8 38 41 30 80 52 50 60 26 (MPa) 83 870 1050 275 1105 1590 1540 2930 705 (MPa) 48 185 234 138 200 207 152 200 70 S6 (MPa) 24 72 90 43 120 131 124 108 27 α1(10–6/°C) –11.0 6.4 6.2 –2.0 –0.1 –0.1 –0.4 4.5 –0.5 α2(10–6/°C) 120 16 16 57 29 18 18 20 18 β1 (10–4/%M) 1.0 1.3 1.1 1.9 0.5 0.4 0.3 0.2 0.2 β2 (10–3/%M) 3.2 3.0 3.0 3.5 3.2 3.1 3.1 3.2 3.2 ρ (g/cm3) 1.13 2.00 2.00 1.38 1.57 1.55 1.60 2.02 1.59 XT 1 XT 2 XC 1 XC 2 XT 1 XT 2 XC 1 XC 2 TX001_ch01_Frame Page 9 Saturday, September 21, 2002 4:47 AM © 2003 by CRC Press LLC