正在加载图片...

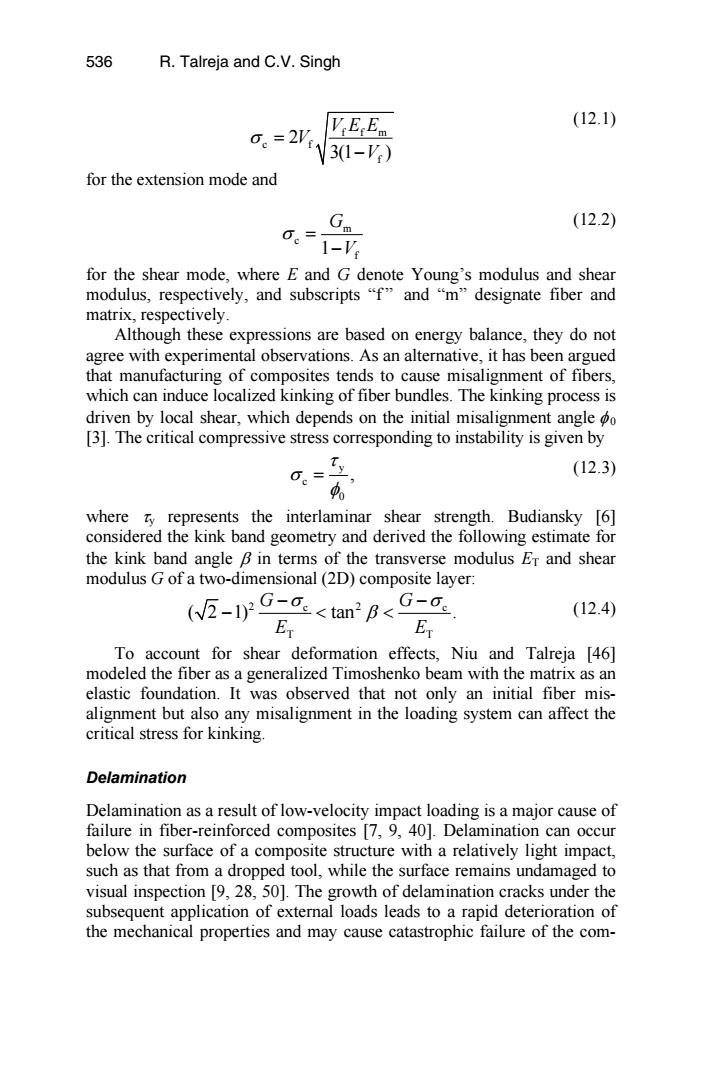

536 R.Talreja and C.V.Singh V:E Em (12.1) 0。=2 31-') for the extension mode and G (12.2) o.1- for the shear mode,where E and G denote Young's modulus and shear modulus,respectively,and subscripts“f”and“m”designate fiber and matrix,respectively. Although these expressions are based on energy balance,they do not agree with experimental observations.As an alternative,it has been argued that manufacturing of composites tends to cause misalignment of fibers, which can induce localized kinking of fiber bundles.The kinking process is driven by local shear,which depends on the initial misalignment angle o [3].The critical compressive stress corresponding to instability is given by (12.3) 4 where zy represents the interlaminar shear strength.Budiansky [6] considered the kink band geometry and derived the following estimate for the kink band angle B in terms of the transverse modulus Er and shear modulus G of a two-dimensional(2D)composite layer: -0 (-1G-<tanB< (12.4) E E To account for shear deformation effects,Niu and Talreja [46] modeled the fiber as a generalized Timoshenko beam with the matrix as an elastic foundation.It was observed that not only an initial fiber mis- alignment but also any misalignment in the loading system can affect the critical stress for kinking. Delamination Delamination as a result of low-velocity impact loading is a major cause of failure in fiber-reinforced composites [7,9,40].Delamination can occur below the surface of a composite structure with a relatively light impact, such as that from a dropped tool,while the surface remains undamaged to visual inspection [9,28,50].The growth of delamination cracks under the subsequent application of external loads leads to a rapid deterioration of the mechanical properties and may cause catastrophic failure of the com-ffm c f f 2 3(1 ) VEE V V σ = − (12.1) for the extension mode and m c f 1 G V σ = − (12.2) for the shear mode, where E and G denote Young’s modulus and shear modulus, respectively, and subscripts “f ” and “m” designate fiber and matrix, respectively. Although these expressions are based on energy balance, they do not agree with experimental observations. As an alternative, it has been argued that manufacturing of composites tends to cause misalignment of fibers, which can induce localized kinking of fiber bundles. The kinking process is driven by local shear, which depends on the initial misalignment angle φ 0 [3]. The critical compressive stress corresponding to instability is given by y c 0 , τ σ φ = (12.3) where τy represents the interlaminar shear strength. Budiansky [6] considered the kink band geometry and derived the following estimate for the kink band angle β in terms of the transverse modulus ET and shear modulus G of a two-dimensional (2D) composite layer: 2 2 c c T T ( 2 1) tan . G G E E σ σ β − − − << (12.4) To account for shear deformation effects, Niu and Talreja [46] modeled the fiber as a generalized Timoshenko beam with the matrix as an elastic foundation. It was observed that not only an initial fiber misalignment but also any misalignment in the loading system can affect the critical stress for kinking. Delamination Delamination as a result of low-velocity impact loading is a major cause of failure in fiber-reinforced composites [7, 9, 40]. Delamination can occur below the surface of a composite structure with a relatively light impact, such as that from a dropped tool, while the surface remains undamaged to visual inspection [9, 28, 50]. The growth of delamination cracks under the subsequent application of external loads leads to a rapid deterioration of the mechanical properties and may cause catastrophic failure of the com- 536 R. Talreja and C.V. Singh