正在加载图片...

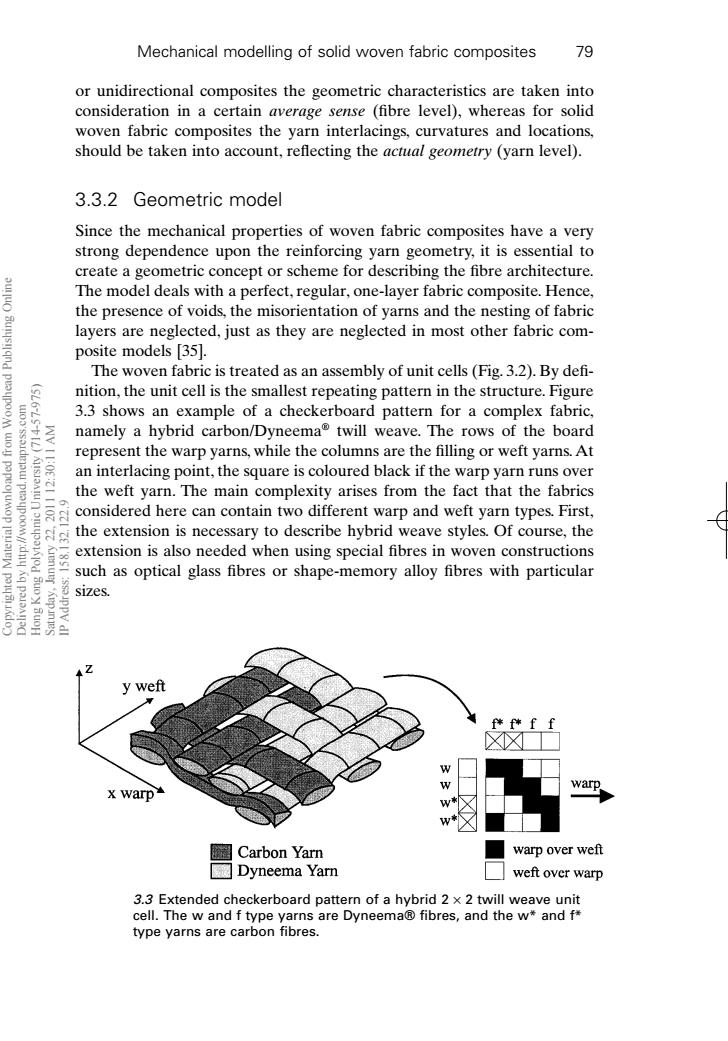

Mechanical modelling of solid woven fabric composites 79 or unidirectional composites the geometric characteristics are taken into consideration in a certain average sense (fibre level),whereas for solid woven fabric composites the yarn interlacings,curvatures and locations, should be taken into account,reflecting the actual geometry (yarn level). 3.3.2 Geometric model Since the mechanical properties of woven fabric composites have a very strong dependence upon the reinforcing yarn geometry,it is essential to create a geometric concept or scheme for describing the fibre architecture. The model deals with a perfect,regular,one-layer fabric composite.Hence, the presence of voids,the misorientation of yarns and the nesting of fabric layers are neglected,just as they are neglected in most other fabric com- posite models [35]. The woven fabric is treated as an assembly of unit cells(Fig.3.2).By defi- nition,the unit cell is the smallest repeating pattern in the structure.Figure 3.3 shows an example of a checkerboard pattern for a complex fabric, namely a hybrid carbon/Dyneema twill weave.The rows of the board L:0 represent the warp yarns,while the columns are the filling or weft yarns.At an interlacing point,the square is coloured black if the warp yarn runs over the weft yarn.The main complexity arises from the fact that the fabrics considered here can contain two different warp and weft yarn types.First, the extension is necessary to describe hybrid weave styles.Of course,the extension is also needed when using special fibres in woven constructions such as optical glass fibres or shape-memory alloy fibres with particular sizes. y weft fff f X warp w* Carbon Yarn warp over weft Dyneema Yarn weft over warp 3.3 Extended checkerboard pattern of a hybrid 2 x 2 twill weave unit cell.The w and f type yarns are Dyneema fibres,and the w*and f* type yarns are carbon fibres.or unidirectional composites the geometric characteristics are taken into consideration in a certain average sense (fibre level), whereas for solid woven fabric composites the yarn interlacings, curvatures and locations, should be taken into account, reflecting the actual geometry (yarn level). 3.3.2 Geometric model Since the mechanical properties of woven fabric composites have a very strong dependence upon the reinforcing yarn geometry, it is essential to create a geometric concept or scheme for describing the fibre architecture. The model deals with a perfect, regular, one-layer fabric composite. Hence, the presence of voids, the misorientation of yarns and the nesting of fabric layers are neglected, just as they are neglected in most other fabric composite models [35]. The woven fabric is treated as an assembly of unit cells (Fig. 3.2). By defi- nition, the unit cell is the smallest repeating pattern in the structure. Figure 3.3 shows an example of a checkerboard pattern for a complex fabric, namely a hybrid carbon/Dyneema® twill weave. The rows of the board represent the warp yarns, while the columns are the filling or weft yarns. At an interlacing point, the square is coloured black if the warp yarn runs over the weft yarn. The main complexity arises from the fact that the fabrics considered here can contain two different warp and weft yarn types. First, the extension is necessary to describe hybrid weave styles. Of course, the extension is also needed when using special fibres in woven constructions such as optical glass fibres or shape-memory alloy fibres with particular sizes. Mechanical modelling of solid woven fabric composites 79 3.3 Extended checkerboard pattern of a hybrid 2 ¥ 2 twill weave unit cell. The w and f type yarns are Dyneema® fibres, and the w* and f* type yarns are carbon fibres. RIC3 7/10/99 7:37 PM Page 79 Copyrighted Material downloaded from Woodhead Publishing Online Delivered by http://woodhead.metapress.com Hong Kong Polytechnic University (714-57-975) Saturday, January 22, 2011 12:30:11 AM IP Address: 158.132.122.9