正在加载图片...

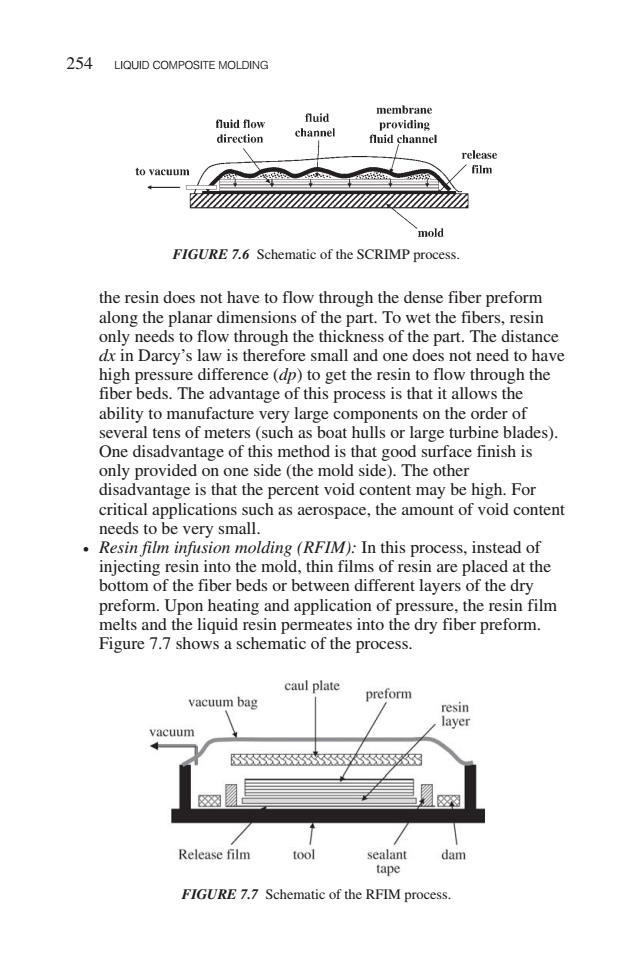

254 LIQUID COMPOSITE MOLDING membrane fluid flow fluid providing direction channel fluid channel release to vacuum film 的 mold FIGURE 7.6 Schematic of the SCRIMP process. the resin does not have to flow through the dense fiber preform along the planar dimensions of the part.To wet the fibers,resin only needs to flow through the thickness of the part.The distance dx in Darcy's law is therefore small and one does not need to have high pressure difference(dp)to get the resin to flow through the fiber beds.The advantage of this process is that it allows the ability to manufacture very large components on the order of several tens of meters (such as boat hulls or large turbine blades) One disadvantage of this method is that good surface finish is only provided on one side (the mold side).The other disadvantage is that the percent void content may be high.For critical applications such as aerospace,the amount of void content needs to be very small. Resin film infusion molding (RFIM):In this process,instead of injecting resin into the mold,thin films of resin are placed at the bottom of the fiber beds or between different layers of the dry preform.Upon heating and application of pressure,the resin film melts and the liquid resin permeates into the dry fiber preform. Figure 7.7 shows a schematic of the process. caul plate preform vacuum bag resin layer vacuum 图 Release film tool sealant dam tape FIGURE 7.7 Schematic of the RFIM process.the resin does not have to flow through the dense fiber preform along the planar dimensions of the part. To wet the fibers, resin only needs to flow through the thickness of the part. The distance dx in Darcy’s law is therefore small and one does not need to have high pressure difference (dp) to get the resin to flow through the fiber beds. The advantage of this process is that it allows the ability to manufacture very large components on the order of several tens of meters (such as boat hulls or large turbine blades). One disadvantage of this method is that good surface finish is only provided on one side (the mold side). The other disadvantage is that the percent void content may be high. For critical applications such as aerospace, the amount of void content needs to be very small. • Resin film infusion molding (RFIM): In this process, instead of injecting resin into the mold, thin films of resin are placed at the bottom of the fiber beds or between different layers of the dry preform. Upon heating and application of pressure, the resin film melts and the liquid resin permeates into the dry fiber preform. Figure 7.7 shows a schematic of the process. FIGURE 7.6 Schematic of the SCRIMP process. 254 LIQUID COMPOSITE MOLDING FIGURE 7.7 Schematic of the RFIM process