正在加载图片...

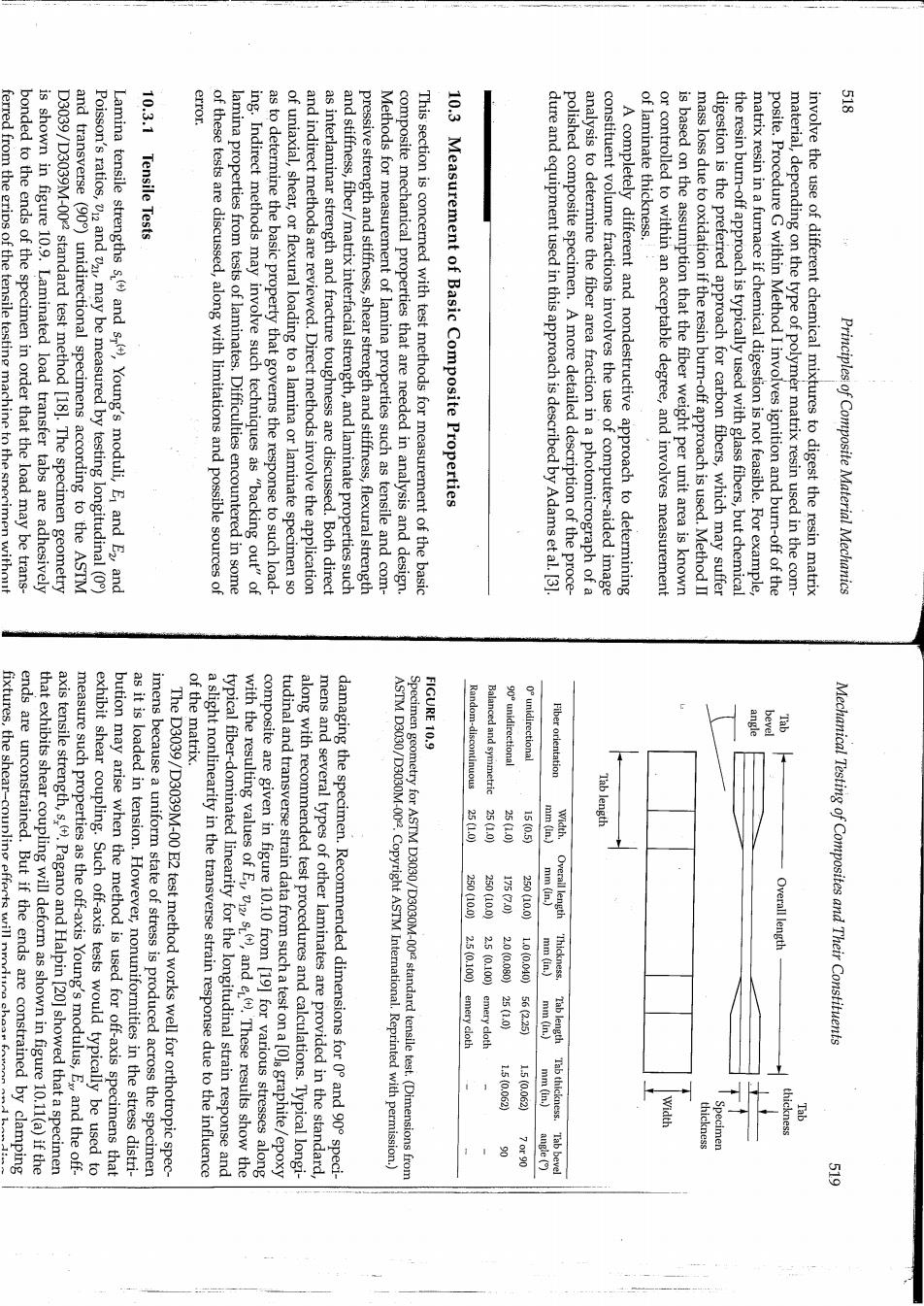

error. 贵 ferred from the grips of the tensile testing machine to the specimen without bonded to the ends of the specimen in order that the load may be trans- is shown in figure 10.9.Laminated load transfer tabs are adhesively D3039/D3039M-002 standard test method [18].The specimen geometry and transverse (90)unidirectional specimens according to the ASTM Poisson's ratios,v12 and vz may be measured by testing longitudinal (0) Lamina tensile strengths s.()and s),Young's moduli,E and E2,and 10.3.1 Tensile Tests of these tests are discussed,along with limitations and possible sources of lamina properties from tests of laminates.Difficulties encountered in some ing.Indirect methods may involve such techniques as "backing out"of as to determine the basic property that governs the response to such load- of uniaxial,shear,or flexural loading to a lamina or laminate specimen so and indirect methods are reviewed.Direct methods involve the application as interlaminar strength and fracture toughness are discussed.Both direct and stiffness,fiber/matrix interfacial strength,and laminate properties such pressive strength and stiffness,shear strength and stiffness,flexural strength Methods for measurement of lamina properties such as tensile and com- composite mechanical properties that are needed in analysis and design. This section is concerned with test methods for measurement of the basic 10.3 Measurement of Basic Composite Properties dure and equipment used in this approach is described by Adamset al.[3] polished composite specimen.A more detailed description of the proce- analysis to determine the fiber area fraction in a photomicrograph of a constituent volume fractions involves the use of computer-aided image A completely different and nondestructive approach to determining of laminate thickness. or controlled to within an acceptable degree,and involves measurement is based on the assumption that the fiber weight per unit area is known mass loss due to oxidation if the resin burn-off approach is used.Method II digestion is the preferred approach for carbon fibers,which may suffer the resin burn-off approach is typically used with glass fibers,but chemical matrix resin in a furnace if chemical digestion is not feasible.For example, posite.Procedure G within Method I involves ignition and burn-off of the material,depending on the type of polymer matrix resin used in the com- involve the use of different chemical mixtures to digest the resin matrix Principles of Composite Material Mechanics ends are unconstrained.But if the ends are constrained by clamping fixtures,the shear-coupling efferts will nrod of the matrix. FIGURE 10.9 Random-discontinuous 90 unidirectional unidirectional Fiber orientation that exhibits shear coupling will deform as shown in figure 10.11(a)if the axis tensile strength,s,().Pagano and Halpin [20]showed that a specimen measure such properties as the off-axis Young's modulus,Ex and the off- exhibit shear coupling.Such off-axis tests would typically be used to bution may arise when the method is used for off-axis specimens that as it is loaded in tension.However,nonuniformities in the stress distri- imens because a uniform state of stress is produced across the specimen The D3039/D3039M-00 E2 test method works well for orthotropic spec- a slight nonlinearity in the transverse strain response due to the influence typical fiber-dominated linearity for the longitudinal strain response and with the resulting values of E),and e().These results show the composite are given in figure 10.10 from [191 for various stresses along tudinal and transverse strain data from such a test on a [Ols graphite/epoxy along with recommended test procedures and calculations.Typical longi- mens and several types of other laminates are provided in the standard. damaging the specimen.Recommended dimensions for 0 and 90 speci- ASTM D3030/D3030M-002.Copyright ASTM International.Reprinted with permission.) Balanced and symmetric ecimen geometry for ASTM D3030/D3030M-00 standard tensile test.(Dimensions from Tab length 25100 25100 150.5 ) 250800 17500 Overall length mm (in.) Overall length 2.5(0.100)emery cloth 250100 20(0080025000 250000010(0.040056235 mm (in.) Thick Mechanical Testing of Composites and Their Constituents 9 emery cloth 15(0.0620 .5(00622 Tab length Tab thickness 工广 留