正在加载图片...

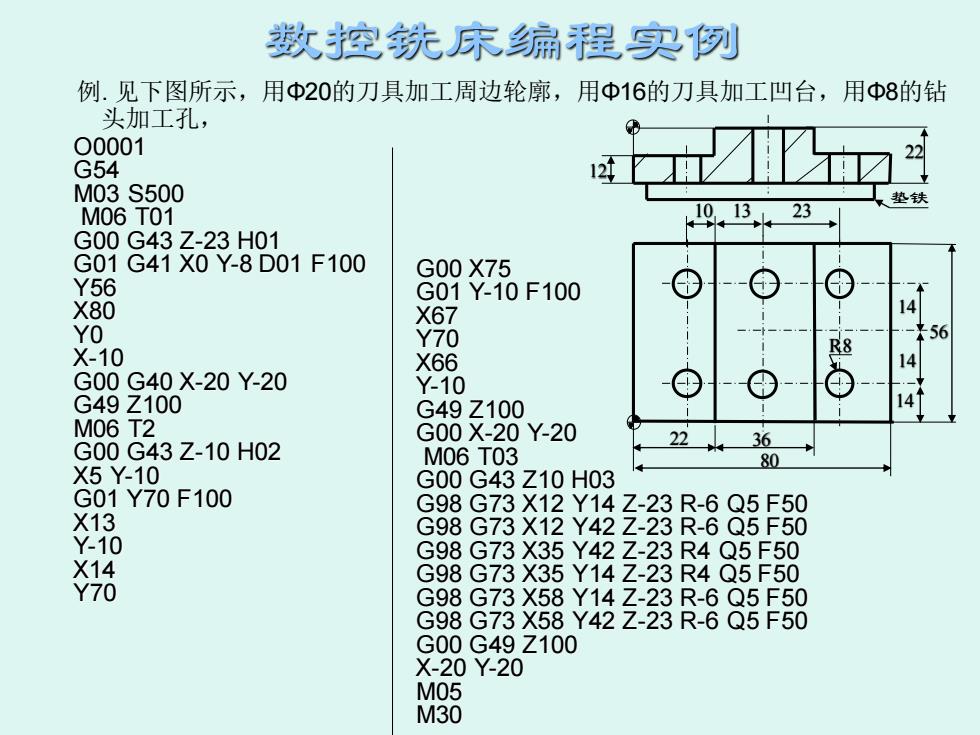

数控銑床编程实例 例.见下图所示,用Φ20的刀具加工周边轮廓,用Φ16的刀具加工凹台,用Φ8的钻 头加工孔, 00001 G54 12 M03S500 垫铁 M06T01 23 G00G43Z-23H01 G01G41X0Y-8D01F100 G00X75 Y56 G01Y-10F100 X80 X67 14 YO Y70 -*56 X-10 R8 X66 G00G40X-20Y-20 Y-10 G49Z100 G49Z100 M06T2 G00X-20Y-20 G00G43Z-10H02 22 36 M06T03 80 X5Y-10 G00G43Z10H03 G01Y70F100 G98G73X12Y14Z-23R-6Q5F50 X13 G98G73X12Y42Z-23R-6Q5F50 Y-10 G98G73X35Y42Z-23R4Q5F50 X14 G98G73X35Y14Z-23R4Q5F50 Y70 G98G73X58Y14Z-23R-6Q5F50 G98G73X58Y42Z-23R-6Q5F50 G00G49Z100 X-20Y-20 M05 M30 例. 见下图所示,用Φ20的刀具加工周边轮廓,用Φ16的刀具加工凹台,用Φ8的钻 头加工孔, 数控铣床编程实例 12 22 垫铁 56 22 80 14 13 23 36 14 10 14 R8 O0001 G54 M03 S500 M06 T01 G00 G43 Z-23 H01 G01 G41 X0 Y-8 D01 F100 Y56 X80 Y0 X-10 G00 G40 X-20 Y-20 G49 Z100 M06 T2 G00 G43 Z-10 H02 X5 Y-10 G01 Y70 F100 X13 Y-10 X14 Y70 G00 X75 G01 Y-10 F100 X67 Y70 X66 Y-10 G49 Z100 G00 X-20 Y-20 M06 T03 G00 G43 Z10 H03 G98 G73 X12 Y14 Z-23 R-6 Q5 F50 G98 G73 X12 Y42 Z-23 R-6 Q5 F50 G98 G73 X35 Y42 Z-23 R4 Q5 F50 G98 G73 X35 Y14 Z-23 R4 Q5 F50 G98 G73 X58 Y14 Z-23 R-6 Q5 F50 G98 G73 X58 Y42 Z-23 R-6 Q5 F50 G00 G49 Z100 X-20 Y-20 M05 M30