事控技术及编程 第十四讲数控加工程序综合练习 主讲:陈德道

第十四讲 数控加工程序综合练习 主讲:陈德道

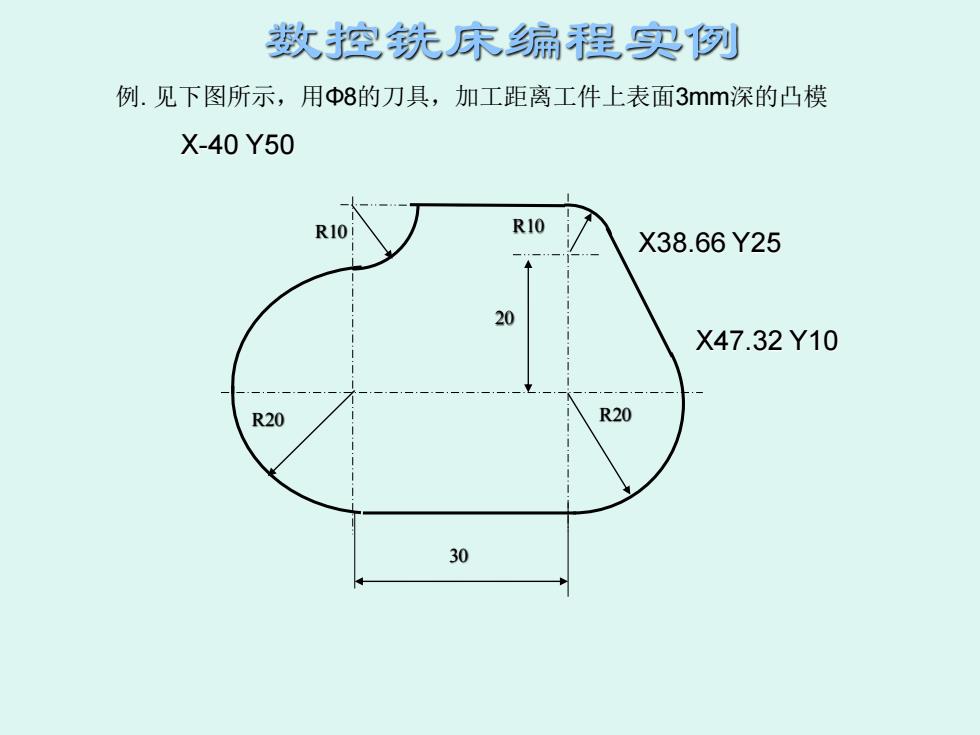

数控统床编程实例 例.见下图所示,用Φ8的刀具,加工距离工件上表面3mm深的凸模 X-40Y50 R10 R10 X38.66Y25 20 X47.32Y10 R20 R20 30

例. 见下图所示,用Φ8的刀具,加工距离工件上表面3mm深的凸模 数控铣床编程实例 R10 30 20 R10 R20 R20 X38.66 Y25 X47.32 Y10 X-40 Y50

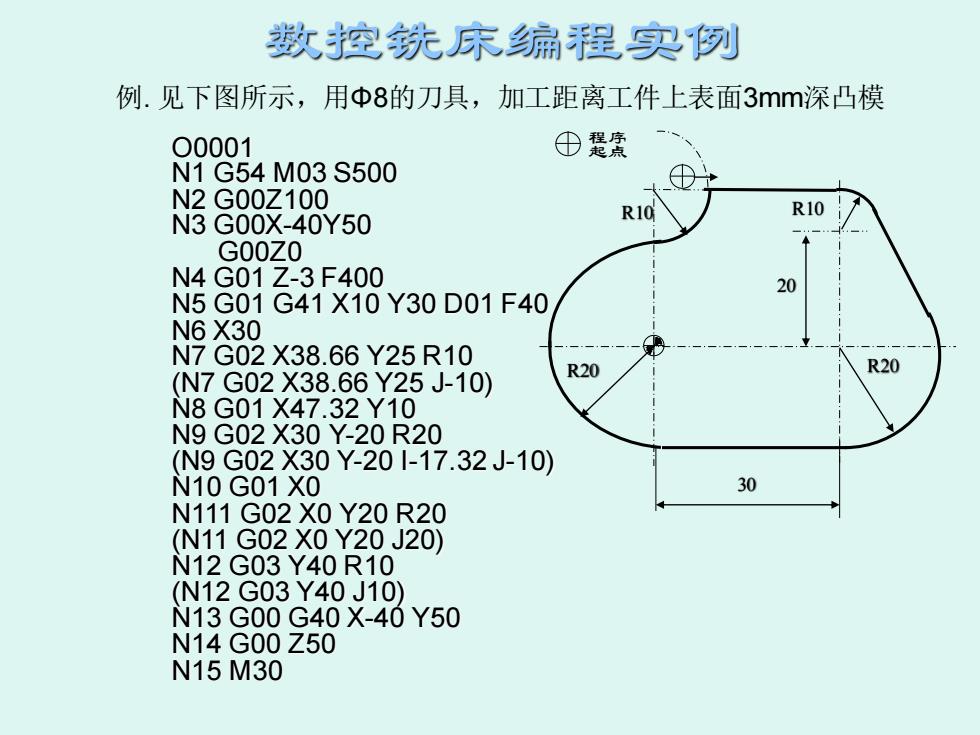

数控统床编程实例 例.见下图所示,用中8的刀具,加工距离工件上表面3mm深凸模 00001 ⊕是度 N1G54M03S500 N2G00Z100 R10 R10 N3G00X-40Y50 G00Z0 N4G01Z-3F400 20 N5G01G41X10Y30D01F40 N6X30 N7G02X38.66Y25R10 R20 R20 (N7G02X38.66Y25J-10) N8G01X47.32Y10 N9G02X30Y-20R20 (N9G02X30Y-20-17.32J-10) N10G01X0 30 N111G02X0Y20R20 (N11G02X0Y20J20) N12G03Y40R10 (N12G03Y40J10) N13G00G40X-40Y50 N14G00Z50 N15M30

例. 见下图所示,用Φ8的刀具,加工距离工件上表面3mm深凸模 数控铣床编程实例 O0001 N1 G54 M03 S500 N2 G00Z100 N3 G00X-40Y50 G00Z0 N4 G01 Z-3 F400 N5 G01 G41 X10 Y30 D01 F40 N6 X30 N7 G02 X38.66 Y25 R10 (N7 G02 X38.66 Y25 J-10) N8 G01 X47.32 Y10 N9 G02 X30 Y-20 R20 (N9 G02 X30 Y-20 I-17.32 J-10) N10 G01 X0 N111 G02 X0 Y20 R20 (N11 G02 X0 Y20 J20) N12 G03 Y40 R10 (N12 G03 Y40 J10) N13 G00 G40 X-40 Y50 N14 G00 Z50 N15 M30 R10 30 20 R10 R20 R20 程序 起点

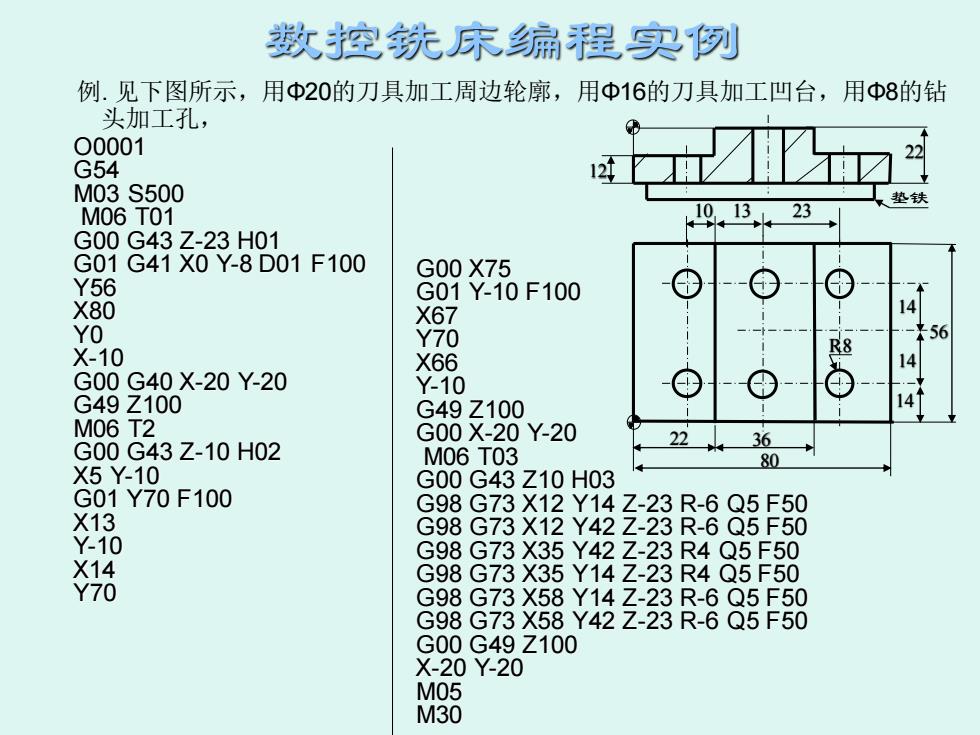

数控銑床编程实例 例.见下图所示,用Φ20的刀具加工周边轮廓,用Φ16的刀具加工凹台,用Φ8的钻 头加工孔, 22 垫铁 13 23 14 --56 R8 14 14 22 36 80

例. 见下图所示,用Φ20的刀具加工周边轮廓,用Φ16的刀具加工凹台,用Φ8的钻 头加工孔, 数控铣床编程实例 56 22 80 14 13 23 36 14 10 14 12 22 垫铁 R8

数控銑床编程实例 例.见下图所示,用Φ20的刀具加工周边轮廓,用Φ16的刀具加工凹台,用Φ8的钻 头加工孔, 00001 G54 12 M03S500 垫铁 M06T01 23 G00G43Z-23H01 G01G41X0Y-8D01F100 G00X75 Y56 G01Y-10F100 X80 X67 14 YO Y70 -*56 X-10 R8 X66 G00G40X-20Y-20 Y-10 G49Z100 G49Z100 M06T2 G00X-20Y-20 G00G43Z-10H02 22 36 M06T03 80 X5Y-10 G00G43Z10H03 G01Y70F100 G98G73X12Y14Z-23R-6Q5F50 X13 G98G73X12Y42Z-23R-6Q5F50 Y-10 G98G73X35Y42Z-23R4Q5F50 X14 G98G73X35Y14Z-23R4Q5F50 Y70 G98G73X58Y14Z-23R-6Q5F50 G98G73X58Y42Z-23R-6Q5F50 G00G49Z100 X-20Y-20 M05 M30

例. 见下图所示,用Φ20的刀具加工周边轮廓,用Φ16的刀具加工凹台,用Φ8的钻 头加工孔, 数控铣床编程实例 12 22 垫铁 56 22 80 14 13 23 36 14 10 14 R8 O0001 G54 M03 S500 M06 T01 G00 G43 Z-23 H01 G01 G41 X0 Y-8 D01 F100 Y56 X80 Y0 X-10 G00 G40 X-20 Y-20 G49 Z100 M06 T2 G00 G43 Z-10 H02 X5 Y-10 G01 Y70 F100 X13 Y-10 X14 Y70 G00 X75 G01 Y-10 F100 X67 Y70 X66 Y-10 G49 Z100 G00 X-20 Y-20 M06 T03 G00 G43 Z10 H03 G98 G73 X12 Y14 Z-23 R-6 Q5 F50 G98 G73 X12 Y42 Z-23 R-6 Q5 F50 G98 G73 X35 Y42 Z-23 R4 Q5 F50 G98 G73 X35 Y14 Z-23 R4 Q5 F50 G98 G73 X58 Y14 Z-23 R-6 Q5 F50 G98 G73 X58 Y42 Z-23 R-6 Q5 F50 G00 G49 Z100 X-20 Y-20 M05 M30

根据以下程序绘制工件图和刀具中心运动轨迹(XOY面内) O0001 N10G54G90X70.000Y0.000Z100.0 N12S2000M03 N18Z10.000 N20G01Z-8.000F300.0 N22G41D01Y30.000F500.0 N24G03X40.000Y0.000I0.000J-30.000 N26G01Y-35.000F1000.0 N28G02X35.000Y-40.000R5.0 N30G01X-35.000 N32G02X-40.000Y-35.000R5.0 N34G01Y35.000 N36G02X-35.000Y40.000R5.0 N38G01X35.000 N40G02X40.000Y35.000R5.0 N42G01Y0.000 N44G03X70.000Y-30.000I30.000J0.000F500 N46G40G01Y0.000 N48Z10.000F2000 N50G00Z100.000M05 N56M30

根据以下程序绘制工件图和刀具中心运动轨迹(XOY面内) O0001 N10 G54 G90X70.000Y0.000 Z100.0 N12 S2000 M03 N18 Z10.000 N20 G01 Z-8.000F300.0 N22 G41 D01 Y30.000 F500.0 N24 G03 X40.000 Y0.000 I0.000 J-30.000 N26 G01Y-35.000 F1000.0 N28 G02 X35.000 Y-40.000R5.0 N30 G01 X-35.000 N32 G02 X-40.000 Y-35.000 R5.0 N34 G01 Y35.000 N36 G02 X-35.000 Y40.000 R5.0 N38 G01 X35.000 N40 G02 X40.000 Y35.000 R5.0 N42 G01 Y0.000 N44 G03 X70.000 Y-30.000 I30.000 J0.000 F500 N46 G40 G01 Y0.000 N48 Z10.000 F2000 N50 G00 Z100.000 M05 N56 M30

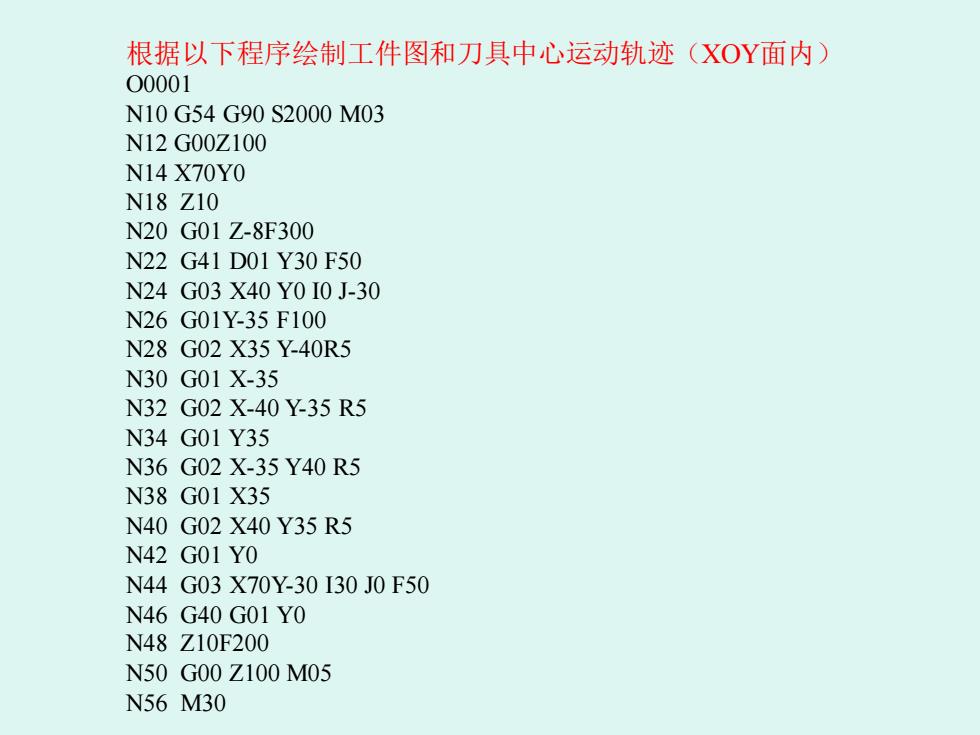

根据以下程序绘制工件图和刀具中心运动轨迹(XOY面内) 00001 N10G54G90S2000M03 N12G00Z100 N14X70Y0 N18Z10 N20G01Z-8F300 N22G41D01Y30F50 N24G03X40Y0I0J-30 N26G01Y-35F100 N28G02X35Y-40R5 N30G01X-35 N32G02X-40Y-35R5 N34G01Y35 N36G02X-35Y40R5 N38G01X35 N40G02X40Y35R5 N42G01Y0 N44G03X70Y-30I30J0F50 N46G40G01Y0 N48Z10F200 N50G00Z100M05 N56M30

根据以下程序绘制工件图和刀具中心运动轨迹(XOY面内) O0001 N10 G54 G90 S2000 M03 N12 G00Z100 N14 X70Y0 N18 Z10 N20 G01 Z-8F300 N22 G41 D01 Y30 F50 N24 G03 X40 Y0 I0 J-30 N26 G01Y-35 F100 N28 G02 X35 Y-40R5 N30 G01 X-35 N32 G02 X-40 Y-35 R5 N34 G01 Y35 N36 G02 X-35 Y40 R5 N38 G01 X35 N40 G02 X40 Y35 R5 N42 G01 Y0 N44 G03 X70Y-30 I30 J0 F50 N46 G40 G01 Y0 N48 Z10F200 N50 G00 Z100 M05 N56 M30

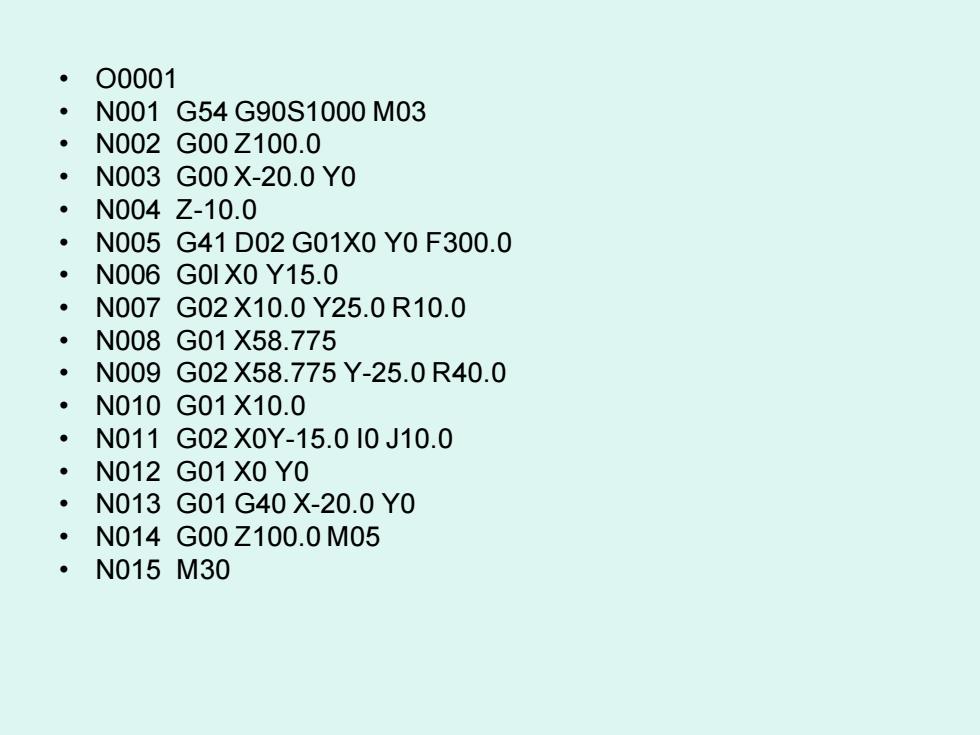

·O0001 ·N001G54G90S1000M03 ·N002G00Z100.0 ·N003G00X-20.0Y0 N004Z-10.0 ·N005G41D02G01X0Y0F300.0 ·N006G01X0Y15.0 N007G02X10.0Y25.0R10.0 ·N008G01X58.775 ·N009G02X58.775Y-25.0R40.0 N010G01X10.0 ·N011G02X0Y-15.010J10.0 ·N012G01X0Y0 ·N013G01G40X-20.0Y0 ·N014G00Z100.0M05 ·N015M30

• O0001 • N001 G54 G90S1000 M03 • N002 G00 Z100.0 • N003 G00 X-20.0 Y0 • N004 Z-10.0 • N005 G41 D02 G01X0 Y0 F300.0 • N006 G0l X0 Y15.0 • N007 G02 X10.0 Y25.0 R10.0 • N008 G01 X58.775 • N009 G02 X58.775 Y-25.0 R40.0 • N010 G01 X10.0 • N011 G02 X0Y-15.0 I0 J10.0 • N012 G01 X0 Y0 • N013 G01 G40 X-20.0 Y0 • N014 G00 Z100.0 M05 • N015 M30

己知零件外围轮廓的零件图如所示,刀具端头已下降到Z=-10mm处,精铣其轮廓。 采用30mm的立铣刀。刀具半径补偿号为D02。工艺路线走刀方向如图所示。采 用绝对坐标输入方法,进刀时刀具从起始点直线切入到轮廓第一点,退刀时刀具从 轮廓最后一点法向直线切出到刀具终止点。请根据已有的语句在括号中填写正确的 程序。 00002 N0040 G92X-70.0Y-40.0Z-10.0 60 N0050 S800M03 N0060 N0070G01X0Y100.0F80.0 N0080 X20.0Y100.0 N0090 G03( N0100 ( N0110 Y40.0 刀具 N0120( 起始点 万具终止点 N0130 G01X0F80.0 70 120 N0140 图5-1-53 N0150M30

O0002 N0040 G92 X-70.0 Y-40.0Z-10.0 N0050 S800 M03 N0060 ( ) N0070 G01 X0 Y100.0 F80.0 N0080 X20.0 Y100.0 N0090 G03( ) N0100 ( ) N0110 Y40.0 N0120 ( ) N0130 G01 X0 F80.0 N0140 ( ) N0150 M30 己知零件外围轮廓的零件图如所示 , 刀具端头已下降到 Z=-10mm 处 , 精铣其轮廓。 采用30 mm 的立铣刀。刀具半径补偿号为 D02 。工艺路线走刀方向如图 所示。采 用绝对坐标输入方法 , 进刀时刀具从起始点直线切入到轮廓第一点 , 退 刀时刀具从 轮廓最后一点法向直线切出到刀具终止点。请根据已有的语句在括号中填写正 确的 程序