正在加载图片...

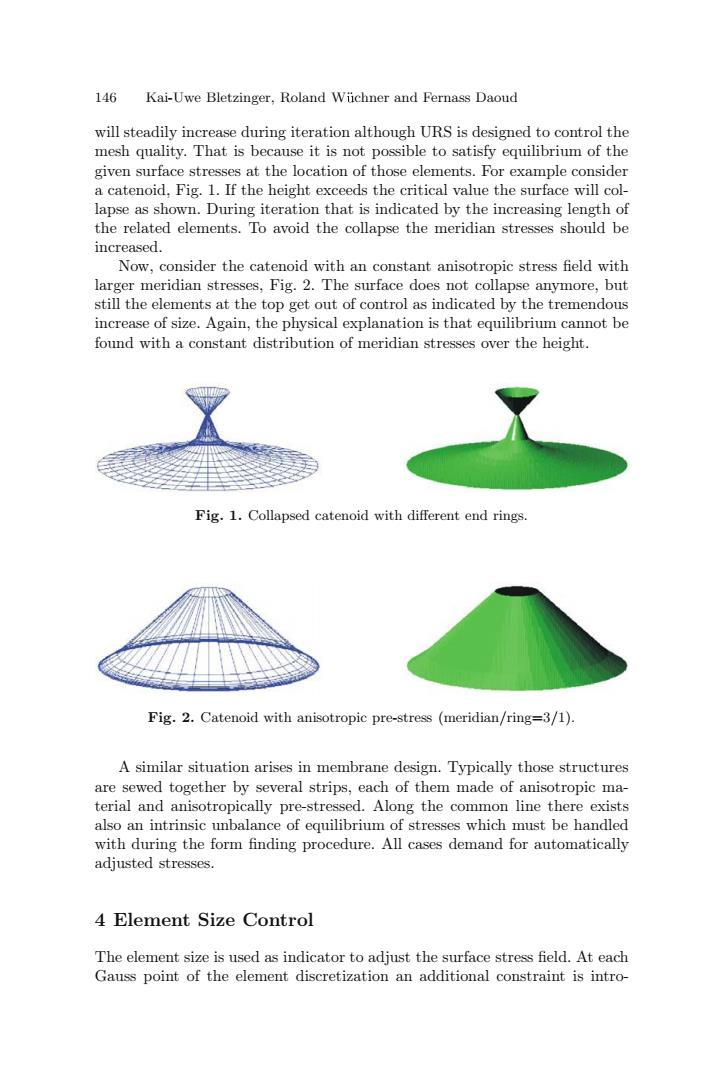

146 Kai-Uwe Bletzinger,Roland Wiichner and Fernass Daoud will steadily increase during iteration although URS is designed to control the mesh quality.That is because it is not possible to satisfy equilibrium of the given surface stresses at the location of those elements.For example consider a catenoid,Fig.1.If the height exceeds the critical value the surface will col- lapse as shown.During iteration that is indicated by the increasing length of the related elements.To avoid the collapse the meridian stresses should be increased. Now,consider the catenoid with an constant anisotropic stress field with larger meridian stresses,Fig.2.The surface does not collapse anymore,but still the elements at the top get out of control as indicated by the tremendous increase of size.Again,the physical explanation is that equilibrium cannot be found with a constant distribution of meridian stresses over the height. Fig.1.Collapsed catenoid with different end rings. Fig.2.Catenoid with anisotropic pre-stress (meridian/ring=3/1). A similar situation arises in membrane design.Typically those structures are sewed together by several strips,each of them made of anisotropic ma- terial and anisotropically pre-stressed.Along the common line there exists also an intrinsic unbalance of equilibrium of stresses which must be handled with during the form finding procedure.All cases demand for automatically adjusted stresses. 4 Element Size Control The element size is used as indicator to adjust the surface stress field.At each Gauss point of the element discretization an additional constraint is intro-146 Kai-Uwe Bletzinger, Roland W¨uchner and Fernass Daoud ¨ will steadily increase during iteration although URS is designed to control the mesh quality. That is because it is not possible to satisfy equilibrium of the given surface stresses at the location of those elements. For example consider a catenoid, Fig. 1. If the height exceeds the critical value the surface will collapse as shown. During iteration that is indicated by the increasing length of the related elements. To avoid the collapse the meridian stresses should be increased. Now, consider the catenoid with an constant anisotropic stress field with larger meridian stresses, Fig. 2. The surface does not collapse anymore, but still the elements at the top get out of control as indicated by the tremendous increase of size. Again, the physical explanation is that equilibrium cannot be found with a constant distribution of meridian stresses over the height. Fig. 1. Collapsed catenoid with different end rings. Fig. 2. Catenoid with anisotropic pre-stress (meridian/ring=3/1). A similar situation arises in membrane design. Typically those structures are sewed together by several strips, each of them made of anisotropic material and anisotropically pre-stressed. Along the common line there exists also an intrinsic unbalance of equilibrium of stresses which must be handled with during the form finding procedure. All cases demand for automatically adjusted stresses. 4 Element Size Control The element size is used as indicator to adjust the surface stress field. At each Gauss point of the element discretization an additional constraint is intro-