正在加载图片...

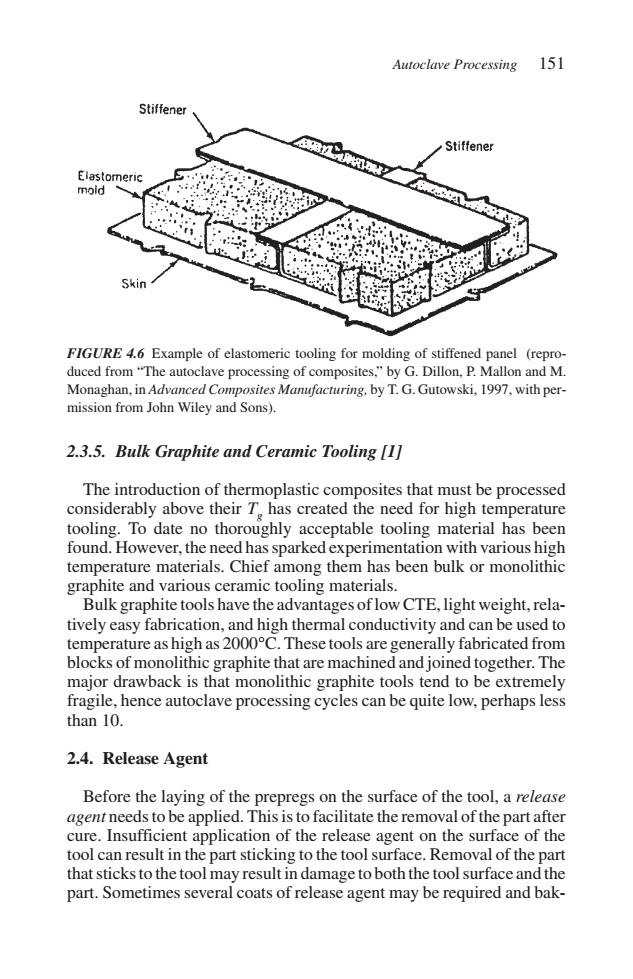

Autoclave Processing 151 Stiffener Stiffener Elastomeric moid Skin FIGURE 4.6 Example of elastomeric tooling for molding of stiffened panel (repro- duced from"The autoclave processing of composites,"by G.Dillon,P.Mallon and M. Monaghan,in Advanced Composites Manufacturing,by T.G.Gutowski,1997,with per- mission from John Wiley and Sons). 2.3.5.Bulk Graphite and Ceramic Tooling [1] The introduction of thermoplastic composites that must be processed considerably above their T,has created the need for high temperature tooling.To date no thoroughly acceptable tooling material has been found.However,the need has sparked experimentation with various high temperature materials.Chief among them has been bulk or monolithic graphite and various ceramic tooling materials. Bulk graphite tools have the advantages of low CTE,light weight,rela- tively easy fabrication,and high thermal conductivity and can be used to temperature as high as 2000C.These tools are generally fabricated from blocks of monolithic graphite that are machined and joined together.The major drawback is that monolithic graphite tools tend to be extremely fragile,hence autoclave processing cycles can be quite low,perhaps less than 10. 2.4.Release Agent Before the laying of the prepregs on the surface of the tool,a release agent needs to be applied.This is to facilitate the removal of the part after cure.Insufficient application of the release agent on the surface of the tool can result in the part sticking to the tool surface.Removal of the part that sticks to the tool may result in damage to both the tool surface and the part.Sometimes several coats of release agent may be required and bak-2.3.5. Bulk Graphite and Ceramic Tooling [1] The introduction of thermoplastic composites that must be processed considerably above their Tg has created the need for high temperature tooling. To date no thoroughly acceptable tooling material has been found. However, the need has sparked experimentation with various high temperature materials. Chief among them has been bulk or monolithic graphite and various ceramic tooling materials. Bulk graphite tools have the advantages of low CTE, light weight, relatively easy fabrication, and high thermal conductivity and can be used to temperature as high as 2000°C. These tools are generally fabricated from blocks of monolithic graphite that are machined and joined together. The major drawback is that monolithic graphite tools tend to be extremely fragile, hence autoclave processing cycles can be quite low, perhaps less than 10. 2.4. Release Agent Before the laying of the prepregs on the surface of the tool, a release agent needs to be applied. This is to facilitate the removal of the part after cure. Insufficient application of the release agent on the surface of the tool can result in the part sticking to the tool surface. Removal of the part that sticks to the tool may result in damage to both the tool surface and the part. Sometimes several coats of release agent may be required and bakAutoclave Processing 151 FIGURE 4.6 Example of elastomeric tooling for molding of stiffened panel (reproduced from “The autoclave processing of composites,” by G. Dillon, P. Mallon and M. Monaghan, in Advanced Composites Manufacturing, by T. G. Gutowski, 1997, with permission from John Wiley and Sons)