正在加载图片...

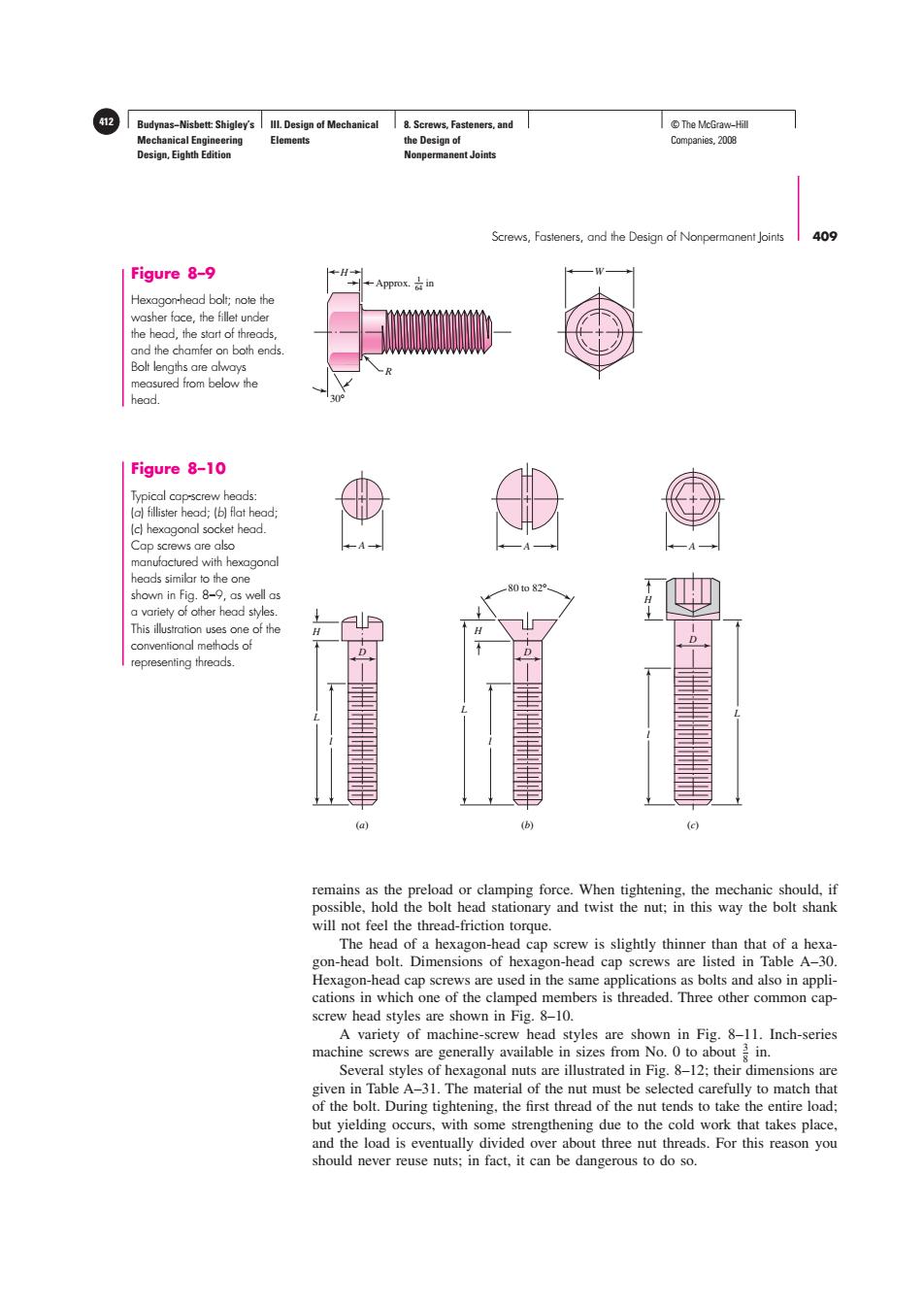

Budynas-Nisbett:Shigley's Ill.Design of Mechanical 8.Screws,Fasteners,and T©The McGraw-Hill Mechanical Engineering Elements the Design of Companies,2008 Design,Eighth Edition Nonpermanent Joints Screws,Fasteners,and the Design of Nonpermanent Joints 409 Figure 8-9 +Approx.in Hexagon-head bolt;note the washer face,the fillet under the head,the start of threads and the chamfer on both ends. Bolt lengths are always measured from below the head. Figure 8-10 Typical cap-screw heads: (a)fillister head;(b)flat head; Icl hexagonal socket head. Cap screws are also manufactured with hexagonal heads similar to the one 80to82 shown in Fig.8-9,as well as a variety of other head styles. This illustration uses one of the conventional methods of epresenting threads. (a) (b) remains as the preload or clamping force.When tightening,the mechanic should,if possible,hold the bolt head stationary and twist the nut;in this way the bolt shank will not feel the thread-friction torque. The head of a hexagon-head cap screw is slightly thinner than that of a hexa- gon-head bolt.Dimensions of hexagon-head cap screws are listed in Table A-30. Hexagon-head cap screws are used in the same applications as bolts and also in appli- cations in which one of the clamped members is threaded.Three other common cap- screw head styles are shown in Fig.8-10. A variety of machine-screw head styles are shown in Fig.8-11.Inch-series machine screws are generally available in sizes from No.0 to about in. Several styles of hexagonal nuts are illustrated in Fig.8-12;their dimensions are given in Table A-31.The material of the nut must be selected carefully to match that of the bolt.During tightening,the first thread of the nut tends to take the entire load; but yielding occurs,with some strengthening due to the cold work that takes place, and the load is eventually divided over about three nut threads.For this reason you should never reuse nuts;in fact,it can be dangerous to do so.Budynas−Nisbett: Shigley’s Mechanical Engineering Design, Eighth Edition III. Design of Mechanical Elements 8. Screws, Fasteners, and the Design of Nonpermanent Joints 412 © The McGraw−Hill Companies, 2008 Screws, Fasteners, and the Design of Nonpermanent Joints 409 Figure 8–9 Hexagon-head bolt; note the washer face, the fillet under the head, the start of threads, and the chamfer on both ends. Bolt lengths are always measured from below the head. l (a) L H A l l L H (b) L H A 80 to 82° (c) A D D D Figure 8–10 Typical cap-screw heads: (a) fillister head; (b) flat head; (c) hexagonal socket head. Cap screws are also manufactured with hexagonal heads similar to the one shown in Fig. 8–9, as well as a variety of other head styles. This illustration uses one of the conventional methods of representing threads. remains as the preload or clamping force. When tightening, the mechanic should, if possible, hold the bolt head stationary and twist the nut; in this way the bolt shank will not feel the thread-friction torque. The head of a hexagon-head cap screw is slightly thinner than that of a hexagon-head bolt. Dimensions of hexagon-head cap screws are listed in Table A–30. Hexagon-head cap screws are used in the same applications as bolts and also in applications in which one of the clamped members is threaded. Three other common capscrew head styles are shown in Fig. 8–10. A variety of machine-screw head styles are shown in Fig. 8–11. Inch-series machine screws are generally available in sizes from No. 0 to about 3 8 in. Several styles of hexagonal nuts are illustrated in Fig. 8–12; their dimensions are given in Table A–31. The material of the nut must be selected carefully to match that of the bolt. During tightening, the first thread of the nut tends to take the entire load; but yielding occurs, with some strengthening due to the cold work that takes place, and the load is eventually divided over about three nut threads. For this reason you should never reuse nuts; in fact, it can be dangerous to do so. 1 64 H Approx. in 30° R W