正在加载图片...

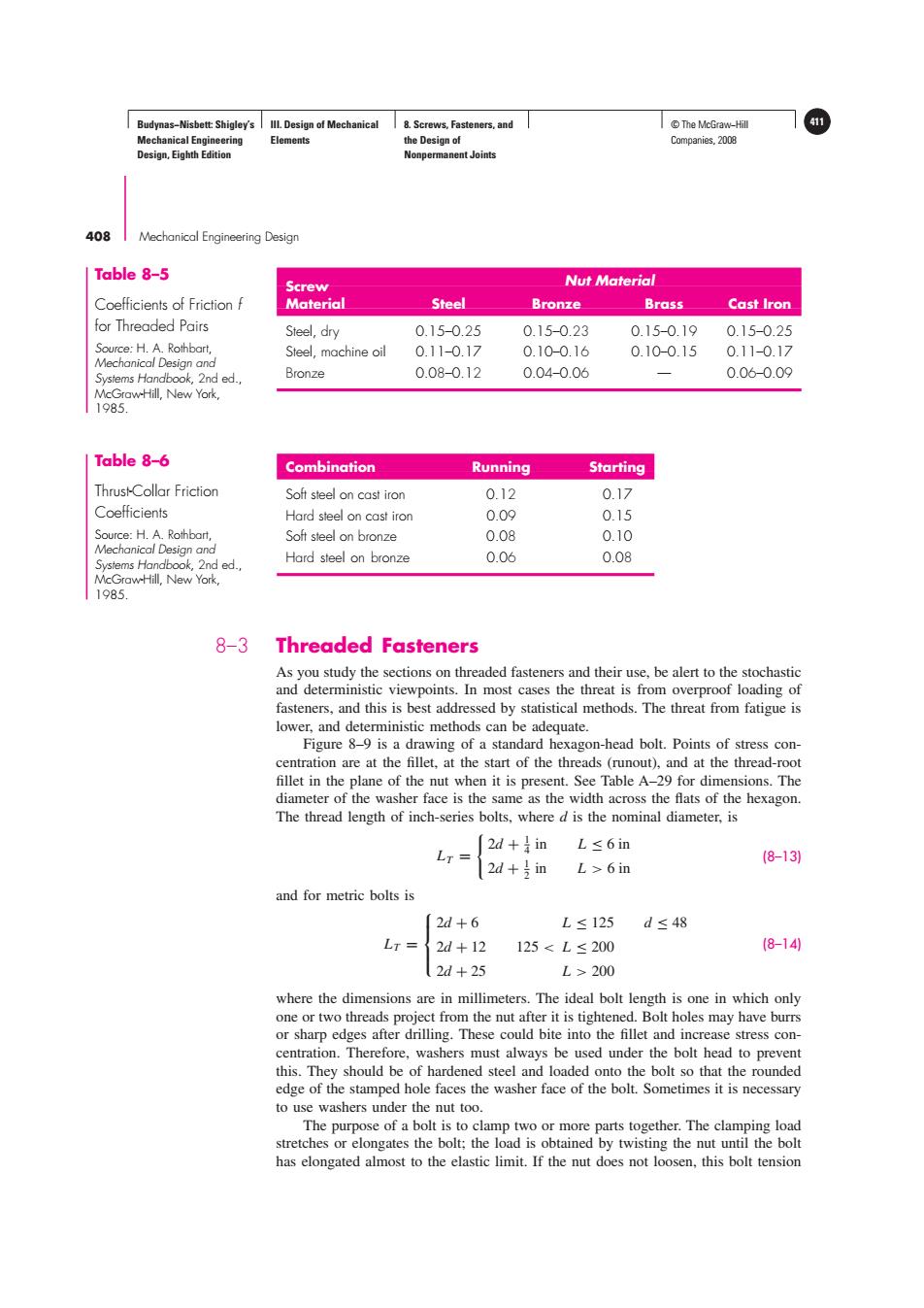

Budynas-Nisbett:Shigley's Ill.Design of Mechanical 8.Screws,Fasteners,and ©The McGraw-Hil 411 Mechanical Engineering Elements the Design of Companies,2008 Design,Eighth Edition Nonpermanent Joints 408 Mechanical Engineering Design Table 8-5 Screw Nut Material Coefficients of Friction f Material Steel Bronze Brass Cast Iron for Threaded Pairs Steel,dry 0.15-0.25 0.15-0.23 0.150.19 0.15-0.25 Source:H.A.Rothbart, Steel,machine oil 0.11-0.17 0.10-0.16 0.10-0.15 0.11-0.17 Mechanical Design and Systems Handbook,2nd ed Bronze 0.08-0.12 0.04-0.06 0.06-0.09 McGraw-Hill,New York, 1985. Table 8-6 Combination Running Starting Thrust-Collar Friction Soft steel on cast iron 0.12 0.17 Coefficients Hard steel on cast iron 0.09 0.15 Source:H.A.Rothbart, Soft steel on bronze 0.08 0.10 Mechanical Design and Systems Handbook,2nd ed., Hard steel on bronze 0.06 0.08 McGraw-Hill,New York 1985. 8-3 Threaded Fasteners As you study the sections on threaded fasteners and their use,be alert to the stochastic and deterministic viewpoints.In most cases the threat is from overproof loading of fasteners,and this is best addressed by statistical methods.The threat from fatigue is lower,and deterministic methods can be adequate Figure 8-9 is a drawing of a standard hexagon-head bolt.Points of stress con- centration are at the fillet,at the start of the threads (runout),and at the thread-root fillet in the plane of the nut when it is present.See Table A-29 for dimensions.The diameter of the washer face is the same as the width across the flats of the hexagon. The thread length of inch-series bolts,where d is the nominal diameter,is 2d+inL≤6in LT= (8-13) 2d+号in L6in and for metric bolts is 2d+6 L≤125 d≤48 LT= 2d+12 125<L≤200 (8-141 2d+25 L>200 where the dimensions are in millimeters.The ideal bolt length is one in which only one or two threads project from the nut after it is tightened.Bolt holes may have burrs or sharp edges after drilling.These could bite into the fillet and increase stress con- centration.Therefore,washers must always be used under the bolt head to prevent this.They should be of hardened steel and loaded onto the bolt so that the rounded edge of the stamped hole faces the washer face of the bolt.Sometimes it is necessary to use washers under the nut too. The purpose of a bolt is to clamp two or more parts together.The clamping load stretches or elongates the bolt;the load is obtained by twisting the nut until the bolt has elongated almost to the elastic limit.If the nut does not loosen,this bolt tensionBudynas−Nisbett: Shigley’s Mechanical Engineering Design, Eighth Edition III. Design of Mechanical Elements 8. Screws, Fasteners, and the Design of Nonpermanent Joints © The McGraw−Hill 411 Companies, 2008 408 Mechanical Engineering Design 8–3 Threaded Fasteners As you study the sections on threaded fasteners and their use, be alert to the stochastic and deterministic viewpoints. In most cases the threat is from overproof loading of fasteners, and this is best addressed by statistical methods. The threat from fatigue is lower, and deterministic methods can be adequate. Figure 8–9 is a drawing of a standard hexagon-head bolt. Points of stress concentration are at the fillet, at the start of the threads (runout), and at the thread-root fillet in the plane of the nut when it is present. See Table A–29 for dimensions. The diameter of the washer face is the same as the width across the flats of the hexagon. The thread length of inch-series bolts, where d is the nominal diameter, is LT = 2d + 1 4 in L ≤ 6 in 2d + 1 2 in L > 6 in (8–13) and for metric bolts is LT = ⎧ ⎪⎨ ⎪⎩ 2d + 6 2d + 12 125 < 2d + 25 L ≤ 125 d ≤ 48 L ≤ 200 L > 200 (8–14) where the dimensions are in millimeters. The ideal bolt length is one in which only one or two threads project from the nut after it is tightened. Bolt holes may have burrs or sharp edges after drilling. These could bite into the fillet and increase stress concentration. Therefore, washers must always be used under the bolt head to prevent this. They should be of hardened steel and loaded onto the bolt so that the rounded edge of the stamped hole faces the washer face of the bolt. Sometimes it is necessary to use washers under the nut too. The purpose of a bolt is to clamp two or more parts together. The clamping load stretches or elongates the bolt; the load is obtained by twisting the nut until the bolt has elongated almost to the elastic limit. If the nut does not loosen, this bolt tension Screw Nut Material Material Steel Bronze Brass Cast Iron Steel, dry 0.15–0.25 0.15–0.23 0.15–0.19 0.15–0.25 Steel, machine oil 0.11–0.17 0.10–0.16 0.10–0.15 0.11–0.17 Bronze 0.08–0.12 0.04–0.06 — 0.06–0.09 Table 8–5 Coefficients of Friction f for Threaded Pairs Source: H. A. Rothbart, Mechanical Design and Systems Handbook, 2nd ed., McGraw-Hill, New York, 1985. Combination Running Starting Soft steel on cast iron 0.12 0.17 Hard steel on cast iron 0.09 0.15 Soft steel on bronze 0.08 0.10 Hard steel on bronze 0.06 0.08 Table 8–6 Thrust-Collar Friction Coefficients Source: H. A. Rothbart, Mechanical Design and Systems Handbook, 2nd ed., McGraw-Hill, New York, 1985