正在加载图片...

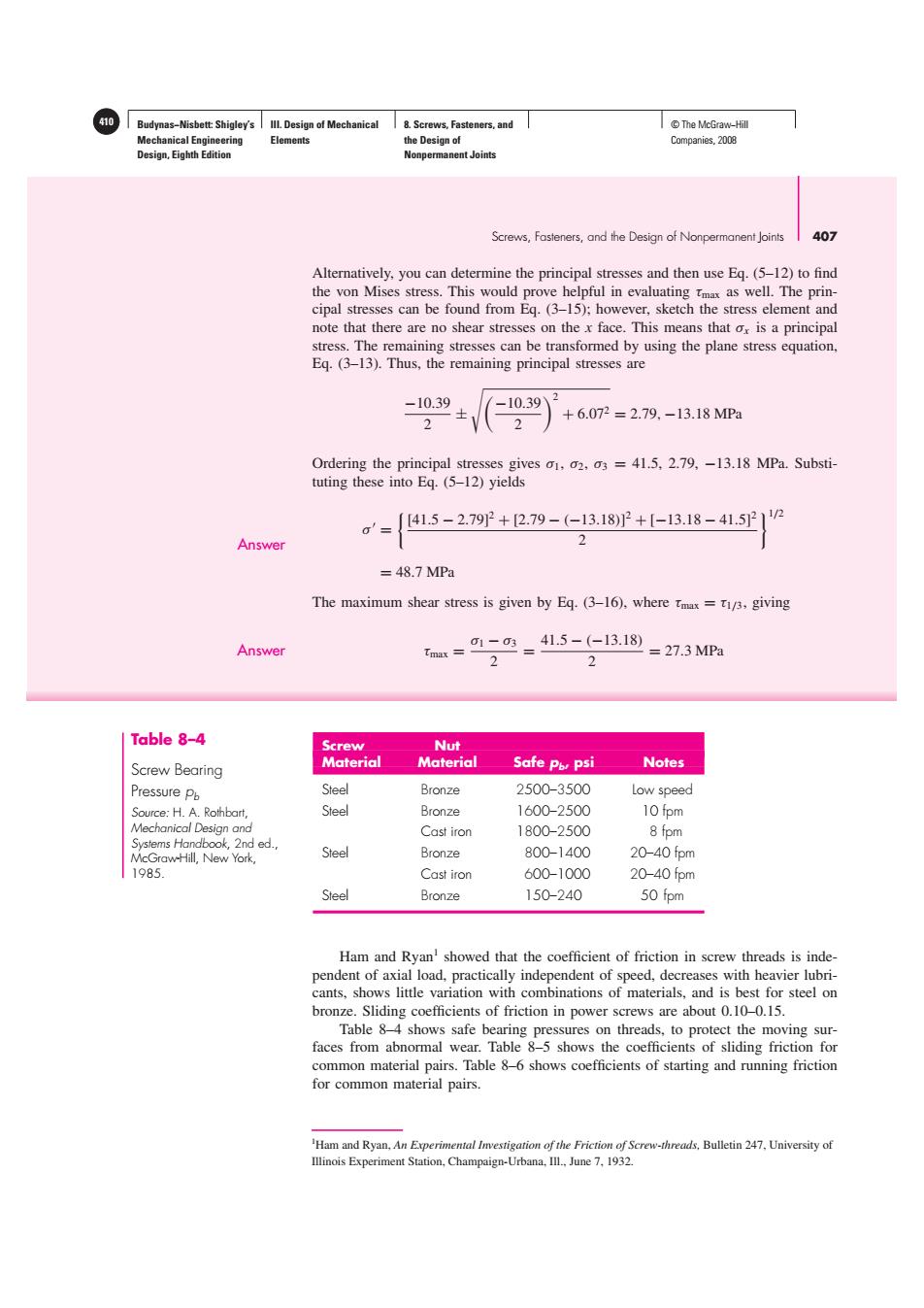

410 Budynas-Nisbett:Shigley's Ill.Design of Mechanical 8.Screws,Fasteners,and ©The McGraw-Hil Mechanical Engineering Elements the Design of Companies,2008 Design,Eighth Edition Nonpermanent Joints Screws,Fasteners,and the Design of Nonpermanent Joints 407 Alternatively,you can determine the principal stresses and then use Eq.(5-12)to find the von Mises stress.This would prove helpful in evaluating max as well.The prin- cipal stresses can be found from Eq.(3-15);however,sketch the stress element and note that there are no shear stresses on the x face.This means that or is a principal stress.The remaining stresses can be transformed by using the plane stress equation. Eq.(3-13).Thus,the remaining principal stresses are -10.39 -10.39 +6.072=2.79,-13.18MPa 2 Ordering the principal stresses gives o1,o2,o3 =41.5,2.79,-13.18 MPa.Substi- tuting these into Eq.(5-12)yields 0 41.5-2.7+2.79-(-13.18)2+[-13.18-41.51p Answer =48.7MPa The maximum shear stress is given by Eq.(3-16),where Tmax=t1/3,giving Answer mx=1、=41.5-(-13.18) =27.3MPa 2 Table 8-4 Screw Nut Screw Bearing Material Material Safe Por psi Notes Pressure pb Steel Bronze 2500-3500 Low speed Source:H.A.Rothbart, Steel Bronze 1600-2500 10 fpm Mechanical Design and Cast iron 1800-2500 8 fpm Systems Handbook,2nd ed., McGraw-Hill,New York, Steel Bronze 800-1400 20-40fpm 1985. Cast iron 600-1000 20-40fpm Steel Bronze 150-240 50 fpm Ham and Ryan'showed that the coefficient of friction in screw threads is inde- pendent of axial load,practically independent of speed,decreases with heavier lubri- cants,shows little variation with combinations of materials,and is best for steel on bronze.Sliding coefficients of friction in power screws are about 0.10-0.15. Table 8-4 shows safe bearing pressures on threads,to protect the moving sur- faces from abnormal wear.Table 8-5 shows the coefficients of sliding friction for common material pairs.Table 8-6 shows coefficients of starting and running friction for common material pairs. Ham and Ryan,An Experimental Imvestigation of the Friction of Screw-threads.Bulletin 247.University of Illinois Experiment Station,Champaign-Urbana,Ill..June 7,1932.Budynas−Nisbett: Shigley’s Mechanical Engineering Design, Eighth Edition III. Design of Mechanical Elements 8. Screws, Fasteners, and the Design of Nonpermanent Joints 410 © The McGraw−Hill Companies, 2008 Screws, Fasteners, and the Design of Nonpermanent Joints 407 Screw Nut Material Material Safe pb, psi Notes Steel Bronze 2500–3500 Low speed Steel Bronze 1600–2500 10 fpm Cast iron 1800–2500 8 fpm Steel Bronze 800–1400 20–40 fpm Cast iron 600–1000 20–40 fpm Steel Bronze 150–240 50 fpm Table 8–4 Screw Bearing Pressure pb Source: H. A. Rothbart, Mechanical Design and Systems Handbook, 2nd ed., McGraw-Hill, New York, 1985. Alternatively, you can determine the principal stresses and then use Eq. (5–12) to find the von Mises stress. This would prove helpful in evaluating τmax as well. The principal stresses can be found from Eq. (3–15); however, sketch the stress element and note that there are no shear stresses on the x face. This means that σx is a principal stress. The remaining stresses can be transformed by using the plane stress equation, Eq. (3–13). Thus, the remaining principal stresses are −10.39 2 ± −10.39 2 2 + 6.072 = 2.79, −13.18 MPa Ordering the principal stresses gives σ1, σ2, σ3 = 41.5, 2.79, −13.18 MPa. Substituting these into Eq. (5–12) yields Answer σ = [41.5 − 2.79]2 + [2.79 − (−13.18)] 2 + [−13.18 − 41.5]2 2 1/2 = 48.7 MPa The maximum shear stress is given by Eq. (3–16), where τmax = τ1/3, giving Answer τmax = σ1 − σ3 2 = 41.5 − (−13.18) 2 = 27.3 MPa 1 Ham and Ryan, An Experimental Investigation of the Friction of Screw-threads, Bulletin 247, University of Illinois Experiment Station, Champaign-Urbana, Ill., June 7, 1932. Ham and Ryan1 showed that the coefficient of friction in screw threads is independent of axial load, practically independent of speed, decreases with heavier lubricants, shows little variation with combinations of materials, and is best for steel on bronze. Sliding coefficients of friction in power screws are about 0.10–0.15. Table 8–4 shows safe bearing pressures on threads, to protect the moving surfaces from abnormal wear. Table 8–5 shows the coefficients of sliding friction for common material pairs. Table 8–6 shows coefficients of starting and running friction for common material pairs.�