正在加载图片...

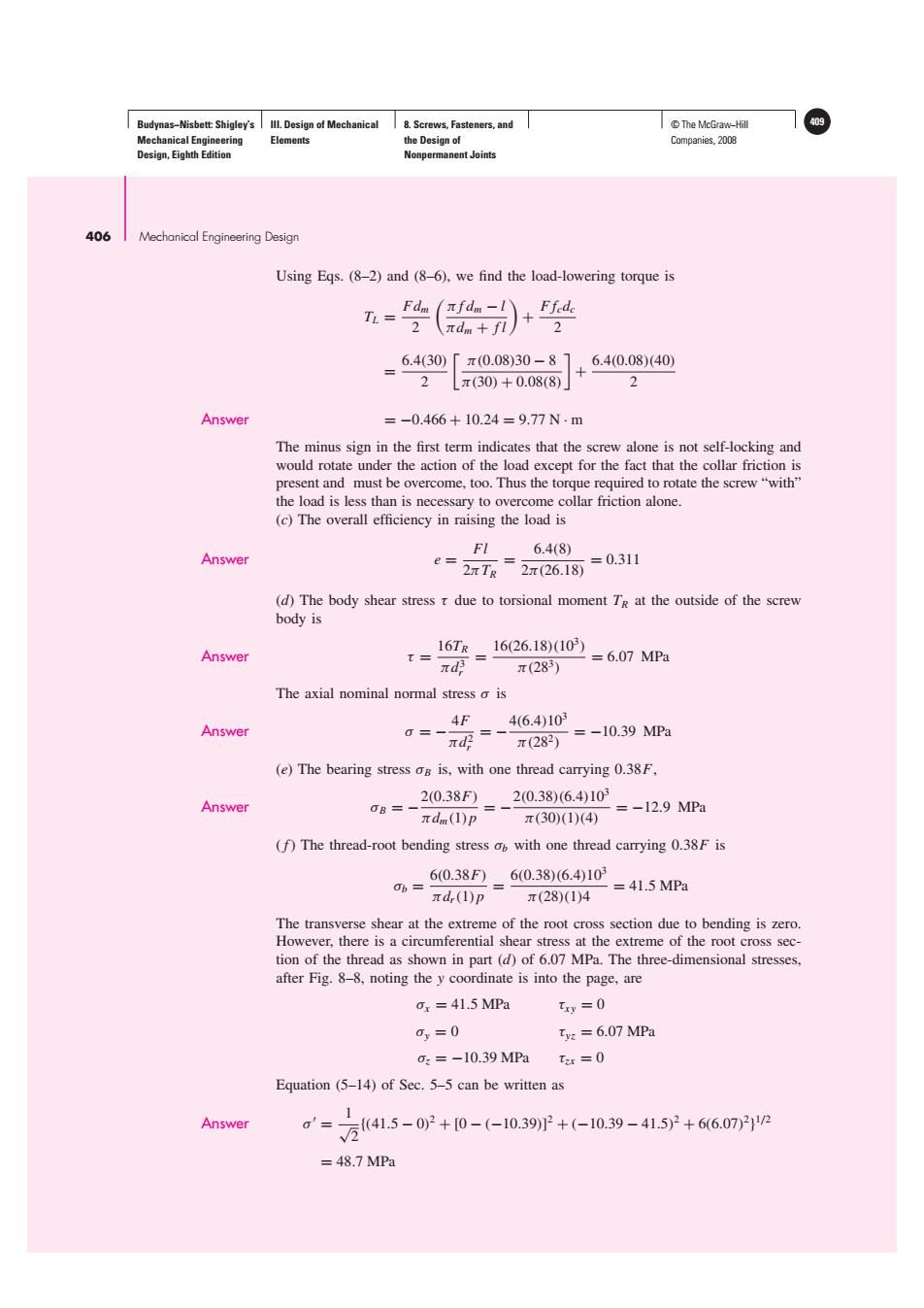

Budynas-Nisbett:Shigley's Ill.Design of Mechanical 8.Screws,Fasteners,and T©The McGraw-Hill 409 Mechanical Engineering Elements the Design of Companies,2008 Design,Eighth Edition Nonpermanent Joints 406 Mechanical Engineering Design Using Eqs.(8-2)and(8-6),we find the load-lowering torque is πdm+fl 6.4(30)「 π(0.08)30-81 6.4(0.08)(40) 2 π(30)+0.08(8) 2 Answer =-0.466+10.24=9.77N-m The minus sign in the first term indicates that the screw alone is not self-locking and would rotate under the action of the load except for the fact that the collar friction is present and must be overcome,too.Thus the torque required to rotate the screw"with" the load is less than is necessary to overcome collar friction alone. (c)The overall efficiency in raising the load is F6.4(8) Answer e=2n7=2π26.18 =0.311 (d)The body shear stress t due to torsional moment Te at the outside of the screw body is Answer 16TR16(26.18)(103) t= =6.07MPa πd π(283) The axial nominal normal stress o is 4F Answer 4(6.4)103 0=- nd= π(282) =-10.39MPa (e)The bearing stress og is,with one thread carrying 0.38F, 2(0.38F)20.38)(6.4)103 Answer OB=- =-12.9MPa πdm(1)p π(30)(1)(4) (f)The thread-root bending stress o with one thread carrying 0.38F is 6(0.38F)6(0.38)(6.4)103 0b= =41.5MPa πd(1)p π(28)(1)4 The transverse shear at the extreme of the root cross section due to bending is zero However,there is a circumferential shear stress at the extreme of the root cross sec- tion of the thread as shown in part(d)of 6.07 MPa.The three-dimensional stresses, after Fig.8-8,noting the y coordinate is into the page.are 0x 41.5 MPa try=0 0=0 Tyz =6.07 MPa o:=-10.39 MPa tax=0 Equation (5-14)of Sec.5-5 can be written as Answer g=万41.5-02+0-(-1039P+(-1039-41.5+660722 =48.7MPaBudynas−Nisbett: Shigley’s Mechanical Engineering Design, Eighth Edition III. Design of Mechanical Elements 8. Screws, Fasteners, and the Design of Nonpermanent Joints © The McGraw−Hill 409 Companies, 2008 406 Mechanical Engineering Design Using Eqs. (8–2) and (8–6), we find the load-lowering torque is TL = Fdm 2 π f dm − l πdm + f l + F fcdc 2 = 6.4(30) 2 π(0.08)30 − 8 π(30) + 0.08(8) + 6.4(0.08)(40) 2 Answer = −0.466 + 10.24 = 9.77 N · m The minus sign in the first term indicates that the screw alone is not self-locking and would rotate under the action of the load except for the fact that the collar friction is present and must be overcome, too. Thus the torque required to rotate the screw “with” the load is less than is necessary to overcome collar friction alone. (c) The overall efficiency in raising the load is Answer e = Fl 2πTR = 6.4(8) 2π(26.18) = 0.311 (d) The body shear stress τ due to torsional moment TR at the outside of the screw body is Answer τ = 16TR πd3 r = 16(26.18)(103) π(283) = 6.07 MPa The axial nominal normal stress σ is Answer σ = − 4F πd2 r = −4(6.4)103 π(282) = −10.39 MPa (e) The bearing stress σB is, with one thread carrying 0.38F, Answer σB = −2(0.38F) πdm(1)p = −2(0.38)(6.4)103 π(30)(1)(4) = −12.9 MPa ( f) The thread-root bending stress σb with one thread carrying 0.38F is σb = 6(0.38F) πdr(1)p = 6(0.38)(6.4)103 π(28)(1)4 = 41.5 MPa The transverse shear at the extreme of the root cross section due to bending is zero. However, there is a circumferential shear stress at the extreme of the root cross section of the thread as shown in part (d) of 6.07 MPa. The three-dimensional stresses, after Fig. 8–8, noting the y coordinate is into the page, are σx = 41.5 MPa τxy = 0 σy = 0 τyz = 6.07 MPa σz = −10.39 MPa τzx = 0 Equation (5–14) of Sec. 5–5 can be written as Answer σ = 1 √2 {(41.5 − 0)2 + [0 − (−10.39)]2 + (−10.39 − 41.5)2 + 6(6.07)2 } 1/2 = 48.7 MPa�