正在加载图片...

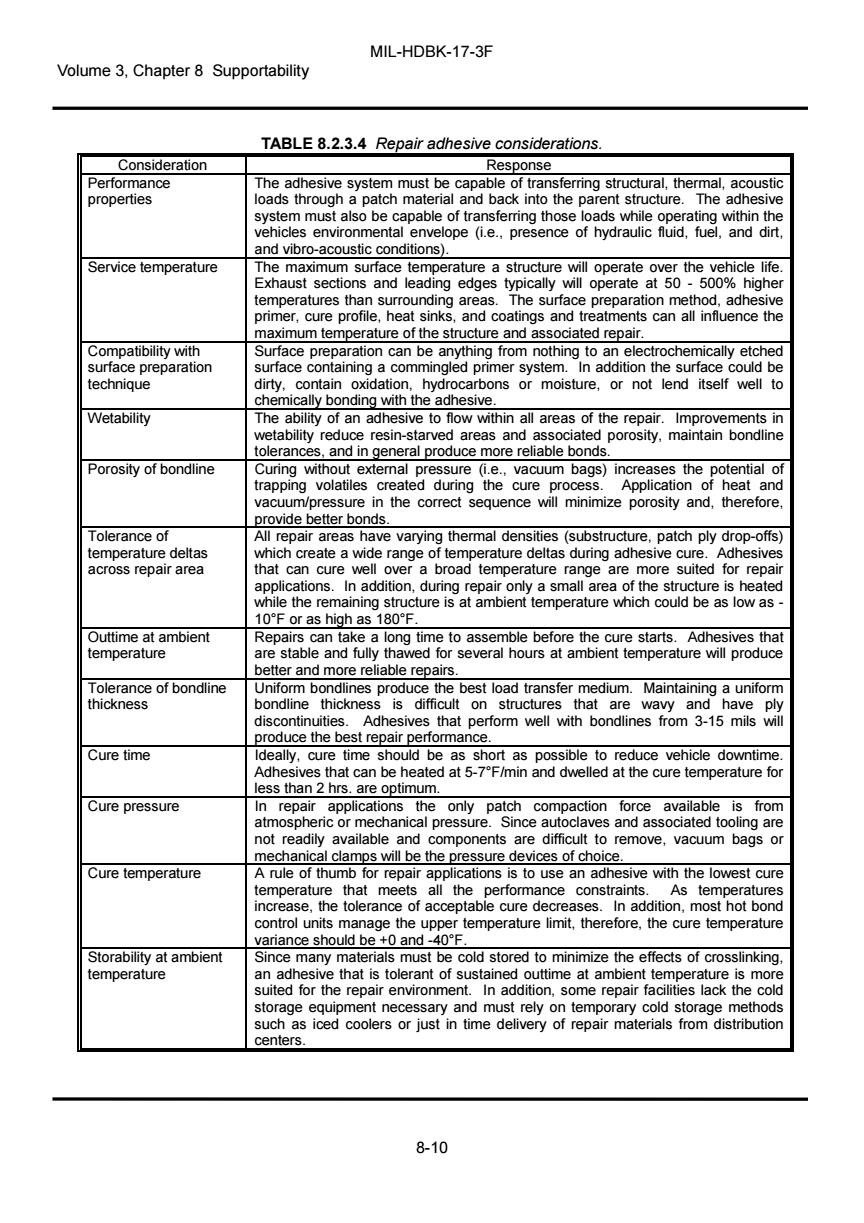

MIL-HDBK-17-3F Volume 3,Chapter 8 Supportability TABLE 8.2.3.4 Repair adhesive considerations. Consideration Response Performance The adhesive system must be capable of transferring structural,thermal,acoustic properties loads through a patch material and back into the parent structure.The adhesive system must also be capable of transferring those loads while operating within the vehicles environmental envelope (i.e.,presence of hydraulic fluid,fuel,and dirt, and vibro-acoustic conditions). Service temperature The maximum surface temperature a structure will operate over the vehicle life. Exhaust sections and leading edges typically will operate at 50-500%higher temperatures than surrounding areas.The surface preparation method,adhesive primer,cure profile,heat sinks,and coatings and treatments can all influence the maximum temperature of the structure and associated repair. Compatibility with Surface preparation can be anything from nothing to an electrochemically etched surface preparation surface containing a commingled primer system.In addition the surface could be technique dirty,contain oxidation,hydrocarbons or moisture,or not lend itself well to chemically bonding with the adhesive. Wetability The ability of an adhesive to flow within all areas of the repair.Improvements in wetability reduce resin-starved areas and associated porosity,maintain bondline tolerances,and in general produce more reliable bonds. Porosity of bondline Curing without external pressure (i.e..vacuum bags)increases the potential of trapping volatiles created during the cure process.Application of heat and vacuum/pressure in the correct sequence will minimize porosity and,therefore, provide better bonds. Tolerance of All repair areas have varying thermal densities (substructure,patch ply drop-offs) temperature deltas which create a wide range of temperature deltas during adhesive cure.Adhesives across repair area that can cure well over a broad temperature range are more suited for repair applications.In addition,during repair only a small area of the structure is heated while the remaining structure is at ambient temperature which could be as low as- 10°℉or as high as180°F. Outtime at ambient Repairs can take a long time to assemble before the cure starts.Adhesives that temperature are stable and fully thawed for several hours at ambient temperature will produce better and more reliable repairs. Tolerance of bondline Uniform bondlines produce the best load transfer medium.Maintaining a uniform thickness bondline thickness is difficult on structures that are wavy and have ply discontinuities.Adhesives that perform well with bondlines from 3-15 mils will produce the best repair performance. Cure time Ideally,cure time should be as short as possible to reduce vehicle downtime. Adhesives that can be heated at 5-7F/min and dwelled at the cure temperature for less than 2 hrs.are optimum. Cure pressure In repair applications the only patch compaction force available is from atmospheric or mechanical pressure.Since autoclaves and associated tooling are not readily available and components are difficult to remove,vacuum bags or mechanical clamps will be the pressure devices of choice. Cure temperature A rule of thumb for repair applications is to use an adhesive with the lowest cure temperature that meets all the performance constraints.As temperatures increase,the tolerance of acceptable cure decreases.In addition,most hot bond control units manage the upper temperature limit,therefore,the cure temperature variance should be +0 and -40F. Storability at ambient Since many materials must be cold stored to minimize the effects of crosslinking, temperature an adhesive that is tolerant of sustained outtime at ambient temperature is more suited for the repair environment.In addition,some repair facilities lack the cold storage equipment necessary and must rely on temporary cold storage methods such as iced coolers or just in time delivery of repair materials from distribution centers. 8-10MIL-HDBK-17-3F Volume 3, Chapter 8 Supportability 8-10 TABLE 8.2.3.4 Repair adhesive considerations. Consideration Response Performance properties The adhesive system must be capable of transferring structural, thermal, acoustic loads through a patch material and back into the parent structure. The adhesive system must also be capable of transferring those loads while operating within the vehicles environmental envelope (i.e., presence of hydraulic fluid, fuel, and dirt, and vibro-acoustic conditions). Service temperature The maximum surface temperature a structure will operate over the vehicle life. Exhaust sections and leading edges typically will operate at 50 - 500% higher temperatures than surrounding areas. The surface preparation method, adhesive primer, cure profile, heat sinks, and coatings and treatments can all influence the maximum temperature of the structure and associated repair. Compatibility with surface preparation technique Surface preparation can be anything from nothing to an electrochemically etched surface containing a commingled primer system. In addition the surface could be dirty, contain oxidation, hydrocarbons or moisture, or not lend itself well to chemically bonding with the adhesive. Wetability The ability of an adhesive to flow within all areas of the repair. Improvements in wetability reduce resin-starved areas and associated porosity, maintain bondline tolerances, and in general produce more reliable bonds. Porosity of bondline Curing without external pressure (i.e., vacuum bags) increases the potential of trapping volatiles created during the cure process. Application of heat and vacuum/pressure in the correct sequence will minimize porosity and, therefore, provide better bonds. Tolerance of temperature deltas across repair area All repair areas have varying thermal densities (substructure, patch ply drop-offs) which create a wide range of temperature deltas during adhesive cure. Adhesives that can cure well over a broad temperature range are more suited for repair applications. In addition, during repair only a small area of the structure is heated while the remaining structure is at ambient temperature which could be as low as - 10°F or as high as 180°F. Outtime at ambient temperature Repairs can take a long time to assemble before the cure starts. Adhesives that are stable and fully thawed for several hours at ambient temperature will produce better and more reliable repairs. Tolerance of bondline thickness Uniform bondlines produce the best load transfer medium. Maintaining a uniform bondline thickness is difficult on structures that are wavy and have ply discontinuities. Adhesives that perform well with bondlines from 3-15 mils will produce the best repair performance. Cure time Ideally, cure time should be as short as possible to reduce vehicle downtime. Adhesives that can be heated at 5-7°F/min and dwelled at the cure temperature for less than 2 hrs. are optimum. Cure pressure In repair applications the only patch compaction force available is from atmospheric or mechanical pressure. Since autoclaves and associated tooling are not readily available and components are difficult to remove, vacuum bags or mechanical clamps will be the pressure devices of choice. Cure temperature A rule of thumb for repair applications is to use an adhesive with the lowest cure temperature that meets all the performance constraints. As temperatures increase, the tolerance of acceptable cure decreases. In addition, most hot bond control units manage the upper temperature limit, therefore, the cure temperature variance should be +0 and -40°F. Storability at ambient temperature Since many materials must be cold stored to minimize the effects of crosslinking, an adhesive that is tolerant of sustained outtime at ambient temperature is more suited for the repair environment. In addition, some repair facilities lack the cold storage equipment necessary and must rely on temporary cold storage methods such as iced coolers or just in time delivery of repair materials from distribution centers