正在加载图片...

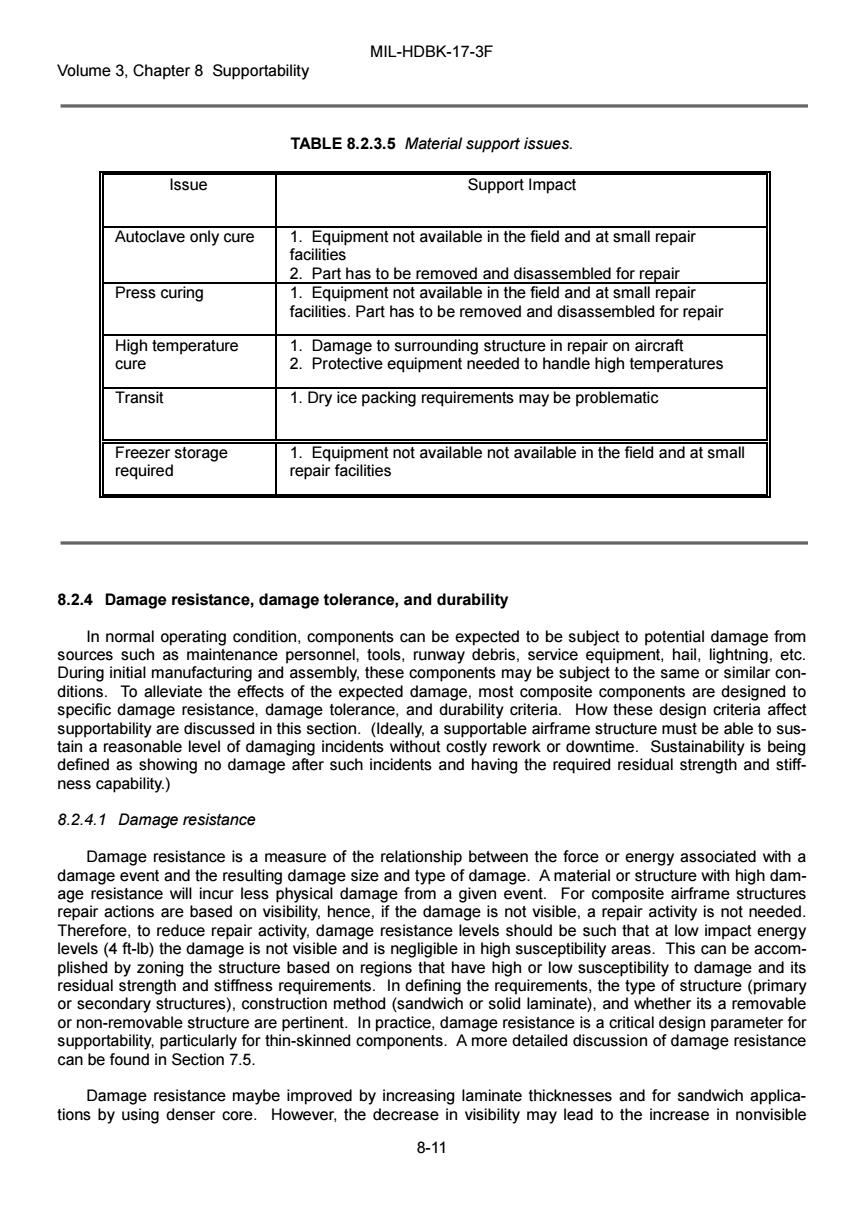

MIL-HDBK-17-3F Volume 3,Chapter 8 Supportability TABLE 8.2.3.5 Material support issues. Issue Support Impact Autoclave only cure 1.Equipment not available in the field and at small repair facilities 2.Part has to be removed and disassembled for repair Press curing 1.Equipment not available in the field and at small repair facilities.Part has to be removed and disassembled for repair High temperature 1.Damage to surrounding structure in repair on aircraft cure 2.Protective equipment needed to handle high temperatures Transit 1.Dry ice packing requirements may be problematic Freezer storage 1.Equipment not available not available in the field and at small required repair facilities 8.2.4 Damage resistance,damage tolerance,and durability In normal operating condition,components can be expected to be subject to potential damage from sources such as maintenance personnel,tools,runway debris,service equipment,hail,lightning,etc. During initial manufacturing and assembly,these components may be subject to the same or similar con- ditions.To alleviate the effects of the expected damage.most composite components are designed to specific damage resistance,damage tolerance,and durability criteria.How these design criteria affect supportability are discussed in this section.(ldeally,a supportable airframe structure must be able to sus- tain a reasonable level of damaging incidents without costly rework or downtime.Sustainability is being defined as showing no damage after such incidents and having the required residual strength and stiff- ness capability.) 8.2.4.1 Damage resistance Damage resistance is a measure of the relationship between the force or energy associated with a damage event and the resulting damage size and type of damage.A material or structure with high dam- age resistance will incur less physical damage from a given event.For composite airframe structures repair actions are based on visibility,hence,if the damage is not visible,a repair activity is not needed. Therefore,to reduce repair activity,damage resistance levels should be such that at low impact energy levels(4 ft-lb)the damage is not visible and is negligible in high susceptibility areas.This can be accom- plished by zoning the structure based on regions that have high or low susceptibility to damage and its residual strength and stiffness requirements.In defining the requirements,the type of structure(primary or secondary structures),construction method(sandwich or solid laminate),and whether its a removable or non-removable structure are pertinent.In practice,damage resistance is a critical design parameter for supportability,particularly for thin-skinned components.A more detailed discussion of damage resistance can be found in Section 7.5. Damage resistance maybe improved by increasing laminate thicknesses and for sandwich applica- tions by using denser core.However,the decrease in visibility may lead to the increase in nonvisible 8-11MIL-HDBK-17-3F Volume 3, Chapter 8 Supportability 8-11 TABLE 8.2.3.5 Material support issues. Issue Support Impact Autoclave only cure 1. Equipment not available in the field and at small repair facilities 2. Part has to be removed and disassembled for repair Press curing 1. Equipment not available in the field and at small repair facilities. Part has to be removed and disassembled for repair High temperature cure 1. Damage to surrounding structure in repair on aircraft 2. Protective equipment needed to handle high temperatures Transit 1. Dry ice packing requirements may be problematic Freezer storage required 1. Equipment not available not available in the field and at small repair facilities 8.2.4 Damage resistance, damage tolerance, and durability In normal operating condition, components can be expected to be subject to potential damage from sources such as maintenance personnel, tools, runway debris, service equipment, hail, lightning, etc. During initial manufacturing and assembly, these components may be subject to the same or similar conditions. To alleviate the effects of the expected damage, most composite components are designed to specific damage resistance, damage tolerance, and durability criteria. How these design criteria affect supportability are discussed in this section. (Ideally, a supportable airframe structure must be able to sustain a reasonable level of damaging incidents without costly rework or downtime. Sustainability is being defined as showing no damage after such incidents and having the required residual strength and stiffness capability.) 8.2.4.1 Damage resistance Damage resistance is a measure of the relationship between the force or energy associated with a damage event and the resulting damage size and type of damage. A material or structure with high damage resistance will incur less physical damage from a given event. For composite airframe structures repair actions are based on visibility, hence, if the damage is not visible, a repair activity is not needed. Therefore, to reduce repair activity, damage resistance levels should be such that at low impact energy levels (4 ft-lb) the damage is not visible and is negligible in high susceptibility areas. This can be accomplished by zoning the structure based on regions that have high or low susceptibility to damage and its residual strength and stiffness requirements. In defining the requirements, the type of structure (primary or secondary structures), construction method (sandwich or solid laminate), and whether its a removable or non-removable structure are pertinent. In practice, damage resistance is a critical design parameter for supportability, particularly for thin-skinned components. A more detailed discussion of damage resistance can be found in Section 7.5. Damage resistance maybe improved by increasing laminate thicknesses and for sandwich applications by using denser core. However, the decrease in visibility may lead to the increase in nonvisible