正在加载图片...

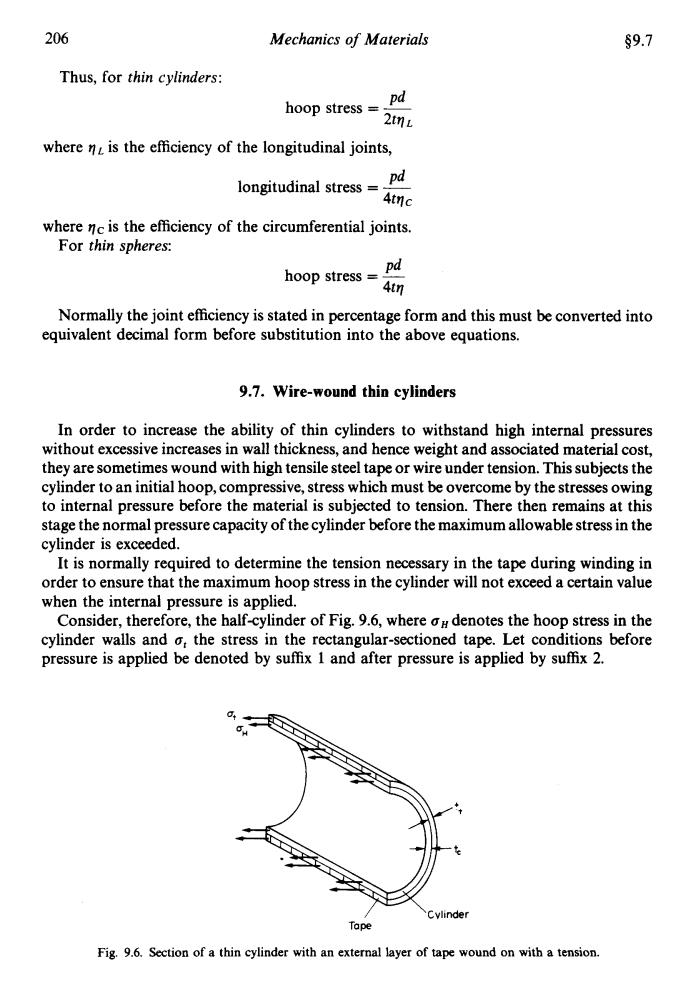

206 Mechanics of Materials 9.7 Thus,for thin cylinders: pd hoop stress 2tnL where n is the efficiency of the longitudinal joints, pd longitudinal stress Atnc where nc is the efficiency of the circumferential joints. For thin spheres: hoop stress pd 4tn Normally the joint efficiency is stated in percentage form and this must be converted into equivalent decimal form before substitution into the above equations. 9.7.Wire-wound thin cylinders In order to increase the ability of thin cylinders to withstand high internal pressures without excessive increases in wall thickness,and hence weight and associated material cost, they are sometimes wound with high tensile steel tape or wire under tension.This subjects the cylinder to an initial hoop,compressive,stress which must be overcome by the stresses owing to internal pressure before the material is subjected to tension.There then remains at this stage the normal pressure capacity of the cylinder before the maximum allowable stress in the cylinder is exceeded. It is normally required to determine the tension necessary in the tape during winding in order to ensure that the maximum hoop stress in the cylinder will not exceed a certain value when the internal pressure is applied. Consider,therefore,the half-cylinder of Fig.9.6,where o#denotes the hoop stress in the cylinder walls and o,the stress in the rectangular-sectioned tape.Let conditions before pressure is applied be denoted by suffix 1 and after pressure is applied by suffix 2. 0 Cylinder Tape Fig.9.6.Section of a thin cylinder with an external layer of tape wound on with a tension.206 Mechanics of Materials 59.7 Thus, for thin cylinders: Pd 2tq L hoop stress = ~ where q is the efficiency of the longitudinal joints, Pd longitudinal stress = - 4tqc where qc is the efficiency of the circumferential joints. For thin spheres: Pd hoop stress = - 4tV Normally the joint efficiency is stated in percentage form and this must be converted into equivalent decimal form before substitution into the above equations. 9.7. Wire-wound thin cylinders In order to increase the ability of thin cylinders to withstand high internal pressures without excessive increases in wall thickness, and hence weight and associated material cost, they are sometimes wound with high tensile steel tape or wire under tension. This subjects the cylinder to an initial hoop, compressive, stress which must be overcome by the stresses owing to internal pressure before the material is subjected to tension. There then remains at this stage the normal pressure capacity of the cylinder before the maximum allowable stress in the cylinder is exceeded. It is normally required to determine the tension necessary in the tape during winding in order to ensure that the maximum hoop stress in the cylinder will not exceed a certain value when the internal pressure is applied. Consider, therefore, the half-cylinder of Fig. 9.6, where oH denotes the hoop stress in the cylinder walls and o, the stress in the rectangular-sectioned tape. Let conditions before pressure is applied be denoted by suffix 1 and after pressure is applied by suffix 2. Fig. 9.6. Section ofa Tope thin cylinder with an external layer of tape wound on with a tension