正在加载图片...

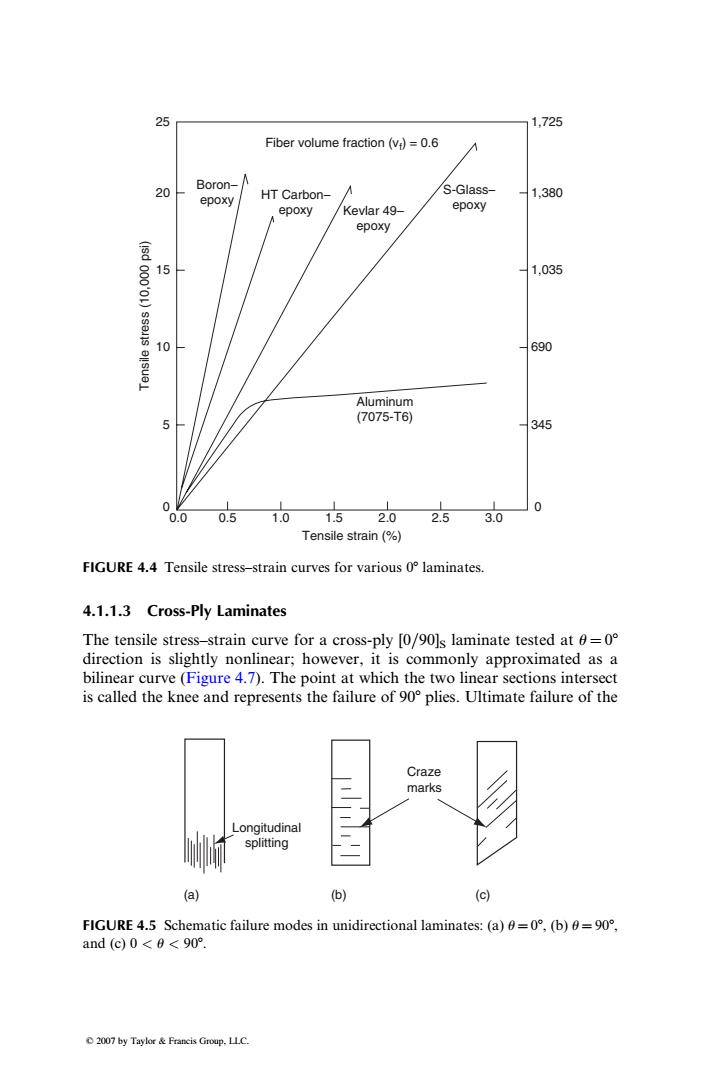

25 1,725 Fiber volume fraction (v)=0.6 A 20 Boron- HT Carbon- S-Glass- 1,380 epoxy epoxy Kevlar 49- epoxy epoxy 15 1.035 10 690 Aluminum 5 (7075-T6) 345 0 0 .0 0.5 1.0 1.52.0 2.5 3.0 Tensile strain (% FIGURE 4.4 Tensile stress-strain curves for various 0 laminates. 4.1.1.3 Cross-Ply Laminates The tensile stress-strain curve for a cross-ply [0/90]s laminate tested at 0=0 direction is slightly nonlinear;however,it is commonly approximated as a bilinear curve(Figure 4.7).The point at which the two linear sections intersect is called the knee and represents the failure of 90 plies.Ultimate failure of the Craze marks Longitudinal splitting (a) (b) (c) FIGURE4.5 Schematic failure modes in unidirectional laminates::(a)0=0°,(b)0=90°, and(c)0<0<90°. 2007 by Taylor&Francis Group.LLC.4.1.1.3 Cross-Ply Laminates The tensile stress–strain curve for a cross-ply [0=90]S laminate tested at u ¼ 08 direction is slightly nonlinear; however, it is commonly approximated as a bilinear curve (Figure 4.7). The point at which the two linear sections intersect is called the knee and represents the failure of 908 plies. Ultimate failure of the 1,725 1,380 1,035 690 345 0 25 Fiber volume fraction (vf ) = 0.6 Boron− epoxy HT Carbon− epoxy Kevlar 49− epoxy S-Glass− epoxy Aluminum (7075-T6) Tensile strain (%) 0.0 0.5 1.0 1.5 2.0 2.5 3.0 20 15 10 Tensile stress (10,000 psi) 5 0 FIGURE 4.4 Tensile stress–strain curves for various 08 laminates. Longitudinal splitting Craze marks (a) (b) (c) FIGURE 4.5 Schematic failure modes in unidirectional laminates: (a) u ¼ 08, (b) u ¼ 908, and (c) 0 < u < 908. 2007 by Taylor & Francis Group, LLC