正在加载图片...

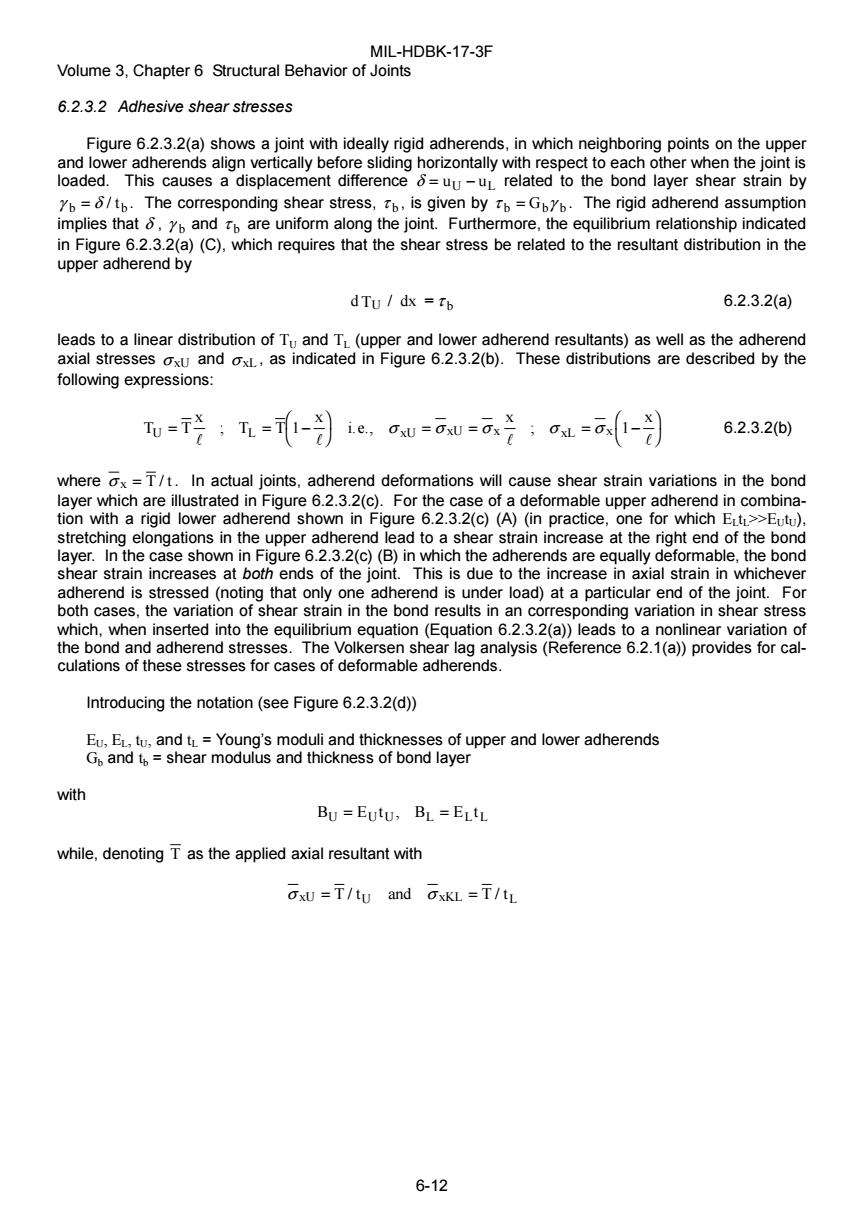

MIL-HDBK-17-3F Volume 3,Chapter 6 Structural Behavior of Joints 6.2.3.2 Adhesive shear stresses Figure 6.2.3.2(a)shows a joint with ideally rigid adherends,in which neighboring points on the upper and lower adherends align vertically before sliding horizontally with respect to each other when the joint is loaded.This causes a displacement difference 6=uu-uL related to the bond layer shear strain by Yb=6/tb.The corresponding shear stress,tb,is given by to=GbYb.The rigid adherend assumption implies that 6,yb and tb are uniform along the joint.Furthermore,the equilibrium relationship indicated in Figure 6.2.3.2(a)(C),which requires that the shear stress be related to the resultant distribution in the upper adherend by dTU/dx =Tb 6.2.3.2(a leads to a linear distribution of Tu and TL(upper and lower adherend resultants)as well as the adherend axial stresses oxu and oxL,as indicated in Figure 6.2.3.2(b).These distributions are described by the following expressions: i.e.Oxu=Oxu=Oxl-os 6.2.3.2(b) whereox=T/t.In actual joints,adherend deformations will cause shear strain variations in the bond layer which are illustrated in Figure 6.2.3.2(c).For the case of a deformable upper adherend in combina- tion with a rigid lower adherend shown in Figure 6.2.3.2(c)(A)(in practice,one for which ELtL>>Eutu). stretching elongations in the upper adherend lead to a shear strain increase at the right end of the bond layer.In the case shown in Figure 6.2.3.2(c)(B)in which the adherends are equally deformable,the bond shear strain increases at both ends of the joint.This is due to the increase in axial strain in whichever adherend is stressed(noting that only one adherend is under load)at a particular end of the joint.For both cases,the variation of shear strain in the bond results in an corresponding variation in shear stress which,when inserted into the equilibrium equation(Equation 6.2.3.2(a))leads to a nonlinear variation of the bond and adherend stresses.The Volkersen shear lag analysis (Reference 6.2.1(a))provides for cal- culations of these stresses for cases of deformable adherends. Introducing the notation(see Figure 6.2.3.2(d)) Eu,EL,tu,and tL=Young's moduli and thicknesses of upper and lower adherends Gp and tp=shear modulus and thickness of bond layer with BU =EutU,BL=ELtL while,denoting T as the applied axial resultant with OxU =T/tu and OxKL=T/tL 6-12MIL-HDBK-17-3F Volume 3, Chapter 6 Structural Behavior of Joints 6-12 6.2.3.2 Adhesive shear stresses Figure 6.2.3.2(a) shows a joint with ideally rigid adherends, in which neighboring points on the upper and lower adherends align vertically before sliding horizontally with respect to each other when the joint is loaded. This causes a displacement difference δ = − u u U L related to the bond layer shear strain by γ b δ b = / t . The corresponding shear stress, τ b , is given by τ γ b = Gb b . The rigid adherend assumption implies that δ , γ b and τ b are uniform along the joint. Furthermore, the equilibrium relationship indicated in Figure 6.2.3.2(a) (C), which requires that the shear stress be related to the resultant distribution in the upper adherend by d TU / dx = τ b 6.2.3.2(a) leads to a linear distribution of TU and TL (upper and lower adherend resultants) as well as the adherend axial stresses σ xU and σ xL , as indicated in Figure 6.2.3.2(b). These distributions are described by the following expressions: T T x T T x i e x x U L xU = =− xU x xL x F H I K == = − F H I AA A A K ; . ., ; 1 1 σσσ σσ 6.2.3.2(b) where σ x = T t / . In actual joints, adherend deformations will cause shear strain variations in the bond layer which are illustrated in Figure 6.2.3.2(c). For the case of a deformable upper adherend in combination with a rigid lower adherend shown in Figure 6.2.3.2(c) (A) (in practice, one for which ELtL>>EUtU), stretching elongations in the upper adherend lead to a shear strain increase at the right end of the bond layer. In the case shown in Figure 6.2.3.2(c) (B) in which the adherends are equally deformable, the bond shear strain increases at both ends of the joint. This is due to the increase in axial strain in whichever adherend is stressed (noting that only one adherend is under load) at a particular end of the joint. For both cases, the variation of shear strain in the bond results in an corresponding variation in shear stress which, when inserted into the equilibrium equation (Equation 6.2.3.2(a)) leads to a nonlinear variation of the bond and adherend stresses. The Volkersen shear lag analysis (Reference 6.2.1(a)) provides for calculations of these stresses for cases of deformable adherends. Introducing the notation (see Figure 6.2.3.2(d)) EU, EL, tU, and tL = Young’s moduli and thicknesses of upper and lower adherends Gb and tb = shear modulus and thickness of bond layer with BU EUtU B E t = = L L L , while, denoting T as the applied axial resultant with σ σ xU = = T t and T t U xKL L / /