正在加载图片...

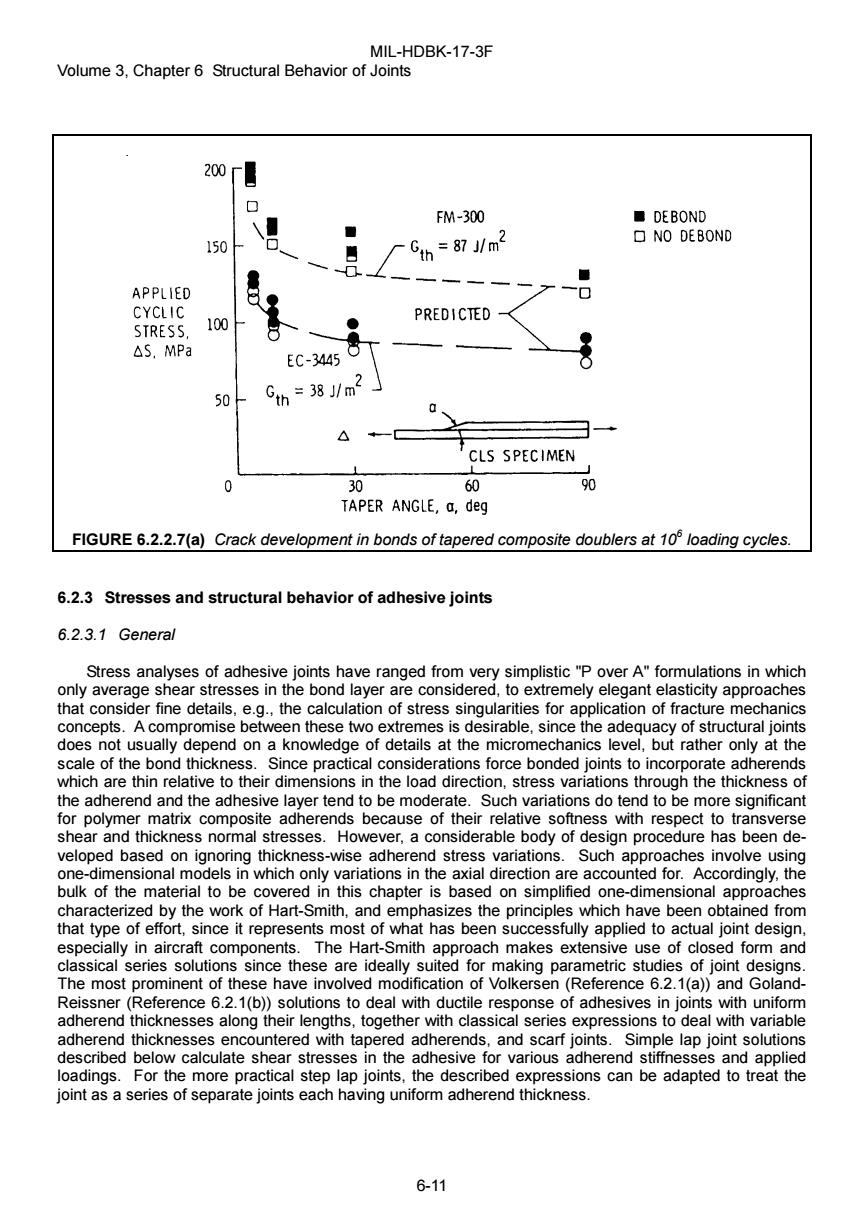

MIL-HDBK-17-3F Volume 3,Chapter 6 Structural Behavior of Joints 200T FM-300 ■DEBOND DNO DEBOND 150 6h=87J/m2 APPLIED CYCLIC PREDICTED STRESS 100 △S.MPa EC-3445 2 50 =38/m △ CLS SPECIMEN 30 60 90 TAPER ANGLE,a,deg FIGURE 6.2.2.7(a)Crack development in bonds of tapered composite doublers at 10 loading cycles. 6.2.3 Stresses and structural behavior of adhesive joints 6.2.3.1 General Stress analyses of adhesive joints have ranged from very simplistic "P over A"formulations in which only average shear stresses in the bond layer are considered,to extremely elegant elasticity approaches that consider fine details,e.g.,the calculation of stress singularities for application of fracture mechanics concepts.A compromise between these two extremes is desirable,since the adequacy of structural joints does not usually depend on a knowledge of details at the micromechanics level,but rather only at the scale of the bond thickness.Since practical considerations force bonded joints to incorporate adherends which are thin relative to their dimensions in the load direction,stress variations through the thickness of the adherend and the adhesive layer tend to be moderate.Such variations do tend to be more significant for polymer matrix composite adherends because of their relative softness with respect to transverse shear and thickness normal stresses.However,a considerable body of design procedure has been de- veloped based on ignoring thickness-wise adherend stress variations.Such approaches involve using one-dimensional models in which only variations in the axial direction are accounted for.Accordingly,the bulk of the material to be covered in this chapter is based on simplified one-dimensional approaches characterized by the work of Hart-Smith,and emphasizes the principles which have been obtained from that type of effort,since it represents most of what has been successfully applied to actual joint design, especially in aircraft components.The Hart-Smith approach makes extensive use of closed form and classical series solutions since these are ideally suited for making parametric studies of joint designs. The most prominent of these have involved modification of Volkersen(Reference 6.2.1(a))and Goland- Reissner(Reference 6.2.1(b))solutions to deal with ductile response of adhesives in joints with uniform adherend thicknesses along their lengths,together with classical series expressions to deal with variable adherend thicknesses encountered with tapered adherends,and scarf joints.Simple lap joint solutions described below calculate shear stresses in the adhesive for various adherend stiffnesses and applied loadings.For the more practical step lap joints,the described expressions can be adapted to treat the joint as a series of separate joints each having uniform adherend thickness. 6-11MIL-HDBK-17-3F Volume 3, Chapter 6 Structural Behavior of Joints 6-11 FIGURE 6.2.2.7(a) Crack development in bonds of tapered composite doublers at 106 loading cycles. 6.2.3 Stresses and structural behavior of adhesive joints 6.2.3.1 General Stress analyses of adhesive joints have ranged from very simplistic "P over A" formulations in which only average shear stresses in the bond layer are considered, to extremely elegant elasticity approaches that consider fine details, e.g., the calculation of stress singularities for application of fracture mechanics concepts. A compromise between these two extremes is desirable, since the adequacy of structural joints does not usually depend on a knowledge of details at the micromechanics level, but rather only at the scale of the bond thickness. Since practical considerations force bonded joints to incorporate adherends which are thin relative to their dimensions in the load direction, stress variations through the thickness of the adherend and the adhesive layer tend to be moderate. Such variations do tend to be more significant for polymer matrix composite adherends because of their relative softness with respect to transverse shear and thickness normal stresses. However, a considerable body of design procedure has been developed based on ignoring thickness-wise adherend stress variations. Such approaches involve using one-dimensional models in which only variations in the axial direction are accounted for. Accordingly, the bulk of the material to be covered in this chapter is based on simplified one-dimensional approaches characterized by the work of Hart-Smith, and emphasizes the principles which have been obtained from that type of effort, since it represents most of what has been successfully applied to actual joint design, especially in aircraft components. The Hart-Smith approach makes extensive use of closed form and classical series solutions since these are ideally suited for making parametric studies of joint designs. The most prominent of these have involved modification of Volkersen (Reference 6.2.1(a)) and GolandReissner (Reference 6.2.1(b)) solutions to deal with ductile response of adhesives in joints with uniform adherend thicknesses along their lengths, together with classical series expressions to deal with variable adherend thicknesses encountered with tapered adherends, and scarf joints. Simple lap joint solutions described below calculate shear stresses in the adhesive for various adherend stiffnesses and applied loadings. For the more practical step lap joints, the described expressions can be adapted to treat the joint as a series of separate joints each having uniform adherend thickness