正在加载图片...

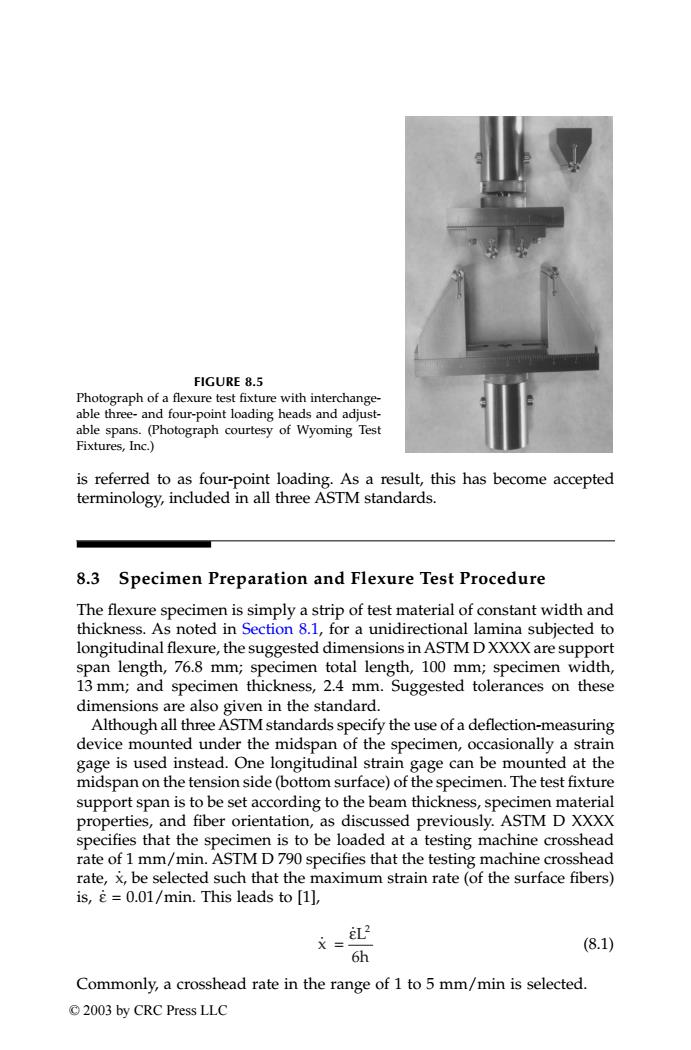

FIGURE 8.5 Photograph of a flexure test fixture with interchange- able three-and four-point loading heads and adjust- able spans.(Photograph courtesy of Wyoming Test Fixtures,Inc.) is referred to as four-point loading.As a result,this has become accepted terminology,included in all three ASTM standards. 8.3 Specimen Preparation and Flexure Test Procedure The flexure specimen is simply a strip of test material of constant width and thickness.As noted in Section 8.1,for a unidirectional lamina subjected to longitudinal flexure,the suggested dimensions in ASTM DXXXX are support span length,76.8 mm;specimen total length,100 mm;specimen width, 13 mm;and specimen thickness,2.4 mm.Suggested tolerances on these dimensions are also given in the standard. Although all three ASTM standards specify the use of a deflection-measuring device mounted under the midspan of the specimen,occasionally a strain gage is used instead.One longitudinal strain gage can be mounted at the midspan on the tension side(bottom surface)of the specimen.The test fixture support span is to be set according to the beam thickness,specimen material properties,and fiber orientation,as discussed previously.ASTM D XXXX specifies that the specimen is to be loaded at a testing machine crosshead rate of 1 mm/min.ASTM D 790 specifies that the testing machine crosshead rate,x,be selected such that the maximum strain rate (of the surface fibers) is,=0.01/min.This leads to [1], ? (8.1) 6h Commonly,a crosshead rate in the range of 1 to 5 mm/min is selected. ©2003 by CRC Press LLCis referred to as four-point loading. As a result, this has become accepted terminology, included in all three ASTM standards. 8.3 Specimen Preparation and Flexure Test Procedure The flexure specimen is simply a strip of test material of constant width and thickness. As noted in Section 8.1, for a unidirectional lamina subjected to longitudinal flexure, the suggested dimensions in ASTM D XXXX are support span length, 76.8 mm; specimen total length, 100 mm; specimen width, 13 mm; and specimen thickness, 2.4 mm. Suggested tolerances on these dimensions are also given in the standard. Although all three ASTM standards specify the use of a deflection-measuring device mounted under the midspan of the specimen, occasionally a strain gage is used instead. One longitudinal strain gage can be mounted at the midspan on the tension side (bottom surface) of the specimen. The test fixture support span is to be set according to the beam thickness, specimen material properties, and fiber orientation, as discussed previously. ASTM D XXXX specifies that the specimen is to be loaded at a testing machine crosshead rate of 1 mm/min. ASTM D 790 specifies that the testing machine crosshead rate, , be selected such that the maximum strain rate (of the surface fibers) is, = 0.01/min. This leads to [1], (8.1) Commonly, a crosshead rate in the range of 1 to 5 mm/min is selected. FIGURE 8.5 Photograph of a flexure test fixture with interchangeable three- and four-point loading heads and adjustable spans. (Photograph courtesy of Wyoming Test Fixtures, Inc.) x˙ ε˙ ˙ ˙ x L 6h = ε 2 TX001_ch08_Frame Page 126 Saturday, September 21, 2002 4:59 AM © 2003 by CRC Press LLC