正在加载图片...

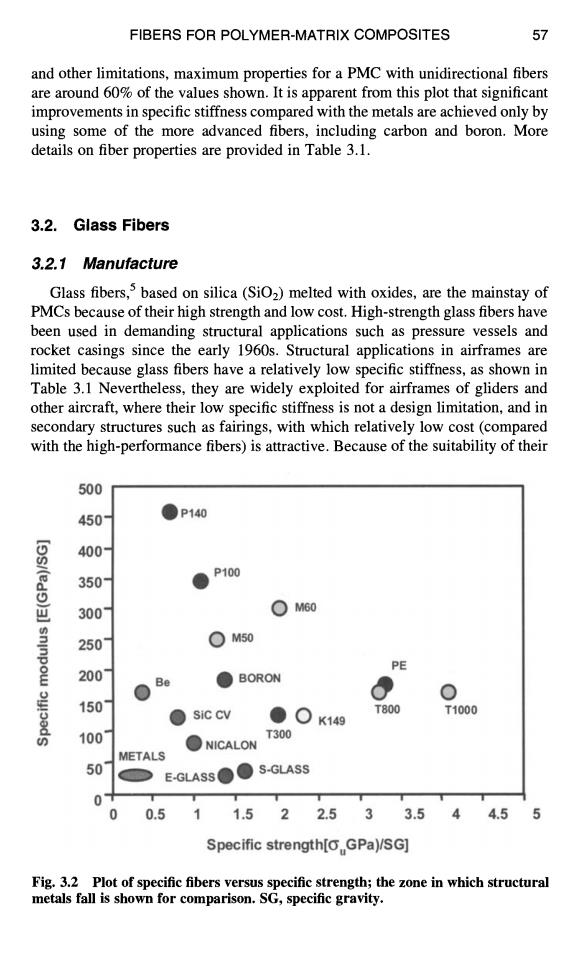

FIBERS FOR POLYMER-MATRIX COMPOSITES 57 and other limitations,maximum properties for a PMC with unidirectional fibers are around 60%of the values shown.It is apparent from this plot that significant improvements in specific stiffness compared with the metals are achieved only by using some of the more advanced fibers,including carbon and boron.More details on fiber properties are provided in Table 3.1. 3.2.Glass Fibers 3.2.1 Manufacture Glass fibers,s based on silica(SiO2)melted with oxides,are the mainstay of PMCs because of their high strength and low cost.High-strength glass fibers have been used in demanding structural applications such as pressure vessels and rocket casings since the early 1960s.Structural applications in airframes are limited because glass fibers have a relatively low specific stiffness,as shown in Table 3.1 Nevertheless,they are widely exploited for airframes of gliders and other aircraft,where their low specific stiffness is not a design limitation,and in secondary structures such as fairings,with which relatively low cost (compared with the high-performance fibers)is attractive.Because of the suitability of their 500 450 ●P140 400 P100 350 300 M60 sn 250 ○M50 PE 200 Be ●BORON 150 ●Sic CV ● K149 T800 T1000 100 ●NICALON T300 METALS 50 E-GLASS(●●S-GLASS 0.5 1 1.52 2.53 3.54 4.55 Specific strength[o GPa)/SG] Fig.3.2 Plot of specific fibers versus specific strength;the zone in which structural metals fall is shown for comparison.SG,specific gravity.FIBERS FOR POLYMER-MATRIX COMPOSITES 57 and other limitations, maximum properties for a PMC with unidirectional fibers are around 60% of the values shown. It is apparent from this plot that significant improvements in specific stiffness compared with the metals are achieved only by using some of the more advanced fibers, including carbon and boron. More details on fiber properties are provided in Table 3.1. 3.2. Glass Fibers 3.2.1 Manufacture Glass fibers, 5 based on silica (SiO2) melted with oxides, are the mainstay of PMCs because of their high strength and low cost. High-strength glass fibers have been used in demanding structural applications such as pressure vessels and rocket casings since the early 1960s. Structural applications in airframes are limited because glass fibers have a relatively low specific stiffness, as shown in Table 3.1 Nevertheless, they are widely exploited for airframes of gliders and other aircraft, where their low specific stiffness is not a design limitation, and in secondary structures such as fairings, with which relatively low cost (compared with the high-performance fibers) is attractive. Because of the suitability of their ~P uJ (n "o o E 500 450- 400- 350- 300" 250- 200- 150" 100" 50" 0 0 • O PIO0 0 M60 (~ i50 PE • • .o.o. O SiC CV • O K149 T800 T300 ~ NIC~LON METALS E-G sseO s.G ss ® TIO00 | | | ! ! ! ! | ! 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 Specific strength[GuGPa)lSG ] Fig. 3.2 Plot of specific fibers versus specific strength; the zone in which structural metals fall is shown for comparison. SG, specific gravity