正在加载图片...

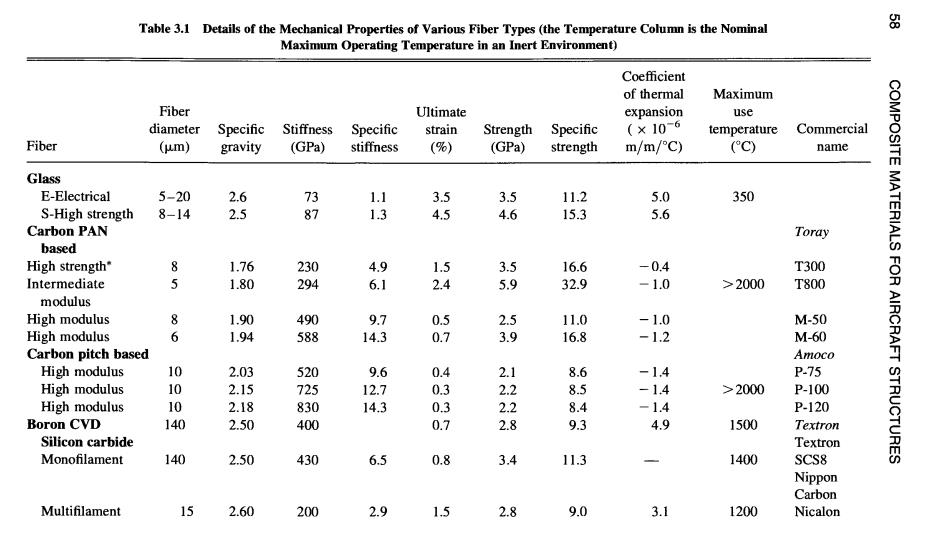

Table 3.1 Details of the Mechanical Properties of Various Fiber Types(the Temperature Column is the Nominal 8粉 Maximum Operating Temperature in an Inert Environment) Coefficient of thermal Maximum Fiber Ultimate expansion use diameter Specific Stiffness Specific strain Strength Specific (×10-6 temperature Commercial Fiber (m) gravity (GPa) stiffness (%) (GPa) strength m/m/C) (C) name Glass E-Electrical 5-20 2.6 73 1.1 3.5 3.5 11.2 5.0 350 S-High strength 8-14 2.5 87 1.3 4.5 4.6 15.3 5.6 Carbon PAN Toray TERIALS based High strength" 8 1.76 230 4.9 1.5 3.5 16.6 -0.4 T300 1.80 294 6.1 2.4 5.9 32.9 -1.0 >2000 T800 FOR Intermediate modulus High modulus 86 1.90 490 9.7 0.5 2.5 11.0 -1.0 M-50 High modulus 1.94 588 14.3 0.7 3.9 16.8 -1.2 M-60 y Carbon pitch based Amoco High modulus 10 2.03 520 9.6 0.4 2.1 8.6 -1.4 P.75 High modulus 10 2.15 725 12.7 0.3 2.2 8.5 -1.4 >2000 P-100 High modulus 10 2.18 830 14.3 0.3 2.2 8.4 -1.4 P-120 Boron CVD 140 2.50 400 0.7 2.8 9.3 4.9 1500 Textron Silicon carbide Textron RUCTURES Monofilament 140 2.50 430 6.5 0.8 3.4 11.3 1400 SCS8 Nippon Carbon Multifilament 15 2.60 200 2.9 1.5 2.8 9.0 3.1 1200 Nicalon58 COMPOSITE MATERIALS FOR AIRCRAFT STRUCTURES e~ °~ ! 0 r~ ~ ~× r~3 r~ ",~ O O o § A A ~ " " II II III I ~,.- o ~ ~ ~.~.~=== ~