正在加载图片...

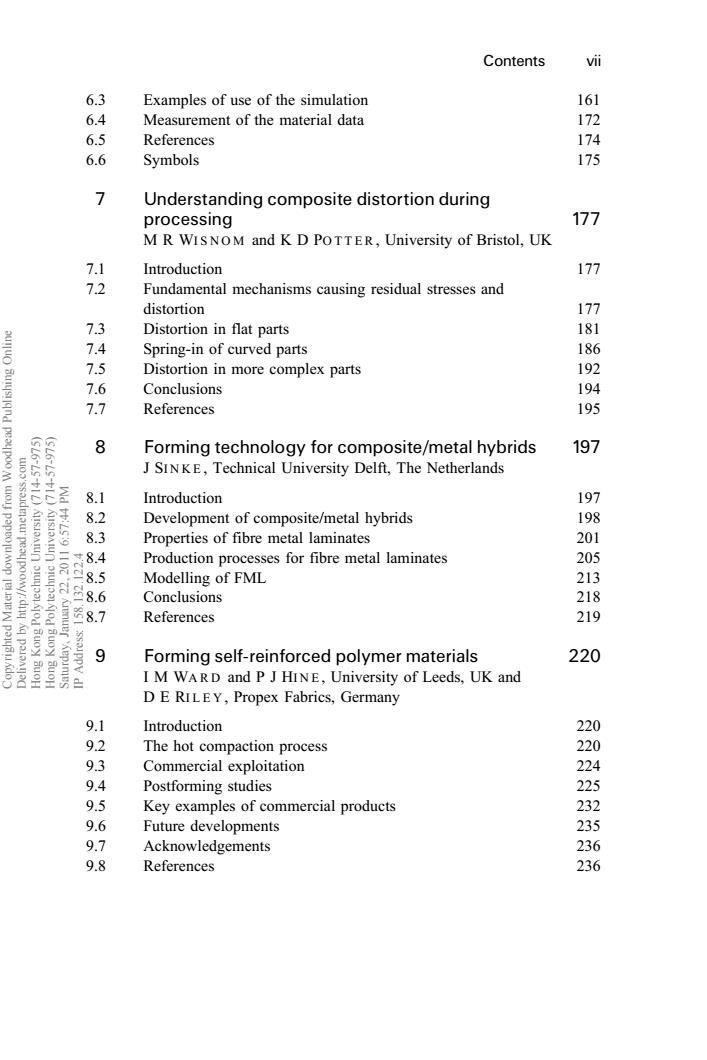

Contents vii 6.3 Examples of use of the simulation 161 6.4 Measurement of the material data 172 6.5 References 174 6.6 Symbols 175 7 Understanding composite distortion during processing 177 M R WIS NOM and K D POTTER,University of Bristol,UK 7.1 Introduction 177 7.2 Fundamental mechanisms causing residual stresses and distortion 177 7.3 Distortion in flat parts 181 7.4 Spring-in of curved parts 186 7.5 Distortion in more complex parts 192 Suysijqnd peaupoo M 7.6 Conclusions 194 7.7 References 195 8 Forming technology for composite/metal hybrids 197 J SINKE,Technical University Delft,The Netherlands woo'ssaudmaur'peaqpoowy/dg 1876-5 8.1 Introduction 197 12.9102. 8.2 Development of composite/metal hybrids 198 8.3 Properties of fibre metal laminates 201 Production processes for fibre metal laminates 205 8.5 Modelling of FML 213 8.6 Conclusions 218 8.7 References 219 9 Forming self-reinforced polymer materials 220 I M WARD and P J HINE,University of Leeds,UK and D E RILEY,Propex Fabrics,Germany 9.1 Introduction 220 9.2 The hot compaction process 220 9.3 Commercial exploitation 224 9.4 Postforming studies 225 9.5 Key examples of commercial products 232 9.6 Future developments 235 9.7 Acknowledgements 236 9.8 References 2366.3 Examples of use of the simulation 161 6.4 Measurement of the material data 172 6.5 References 174 6.6 Symbols 175 7 Understanding composite distortion during processing 177 M R WI S N O M and K D PO T T E R , University of Bristol, UK 7.1 Introduction 177 7.2 Fundamental mechanisms causing residual stresses and distortion 177 7.3 Distortion in flat parts 181 7.4 Spring-in of curved parts 186 7.5 Distortion in more complex parts 192 7.6 Conclusions 194 7.7 References 195 8 Forming technology for composite/metal hybrids 197 J SI N K E , Technical University Delft, The Netherlands 8.1 Introduction 197 8.2 Development of composite/metal hybrids 198 8.3 Properties of fibre metal laminates 201 8.4 Production processes for fibre metal laminates 205 8.5 Modelling of FML 213 8.6 Conclusions 218 8.7 References 219 9 Forming self-reinforced polymer materials 220 I M WA R D and P J HI N E , University of Leeds, UK and D E RI L E Y , Propex Fabrics, Germany 9.1 Introduction 220 9.2 The hot compaction process 220 9.3 Commercial exploitation 224 9.4 Postforming studies 225 9.5 Key examples of commercial products 232 9.6 Future developments 235 9.7 Acknowledgements 236 9.8 References 236 Contents vii Copyrighted Material downloaded from Woodhead Publishing Online Delivered by http://woodhead.metapress.com Hong Kong Polytechnic University (714-57-975) Hong Kong Polytechnic University (714-57-975) Saturday, January 22, 2011 6:57:44 PM IP Address: 158.132.122.4