正在加载图片...

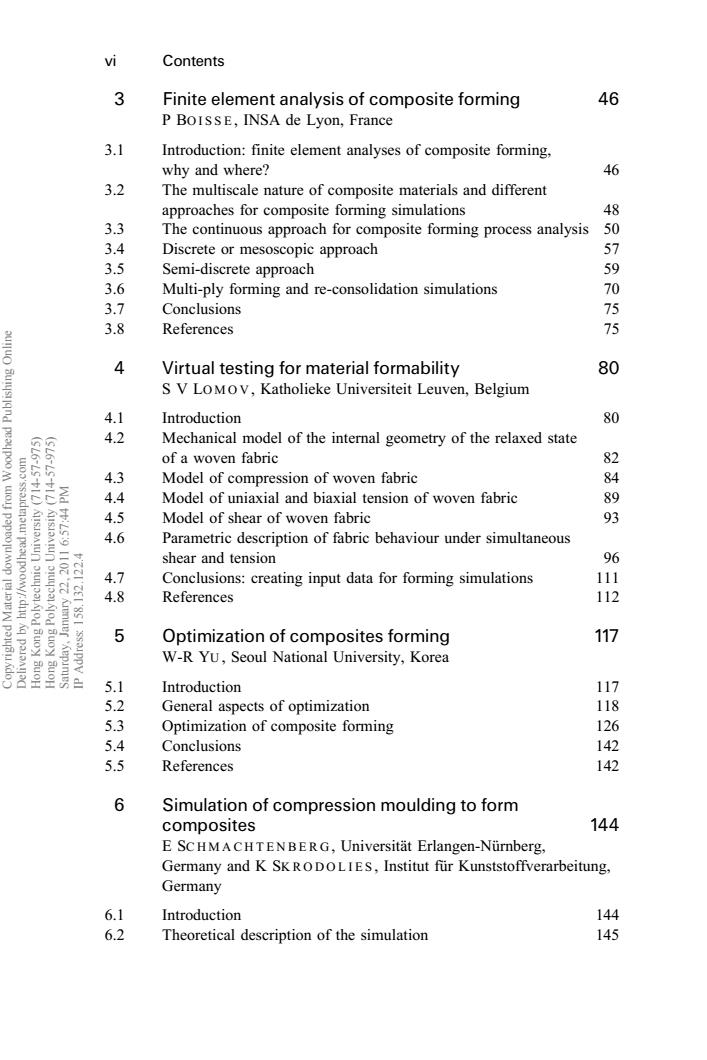

vi Contents 3 Finite element analysis of composite forming 46 P BOISSE,INSA de Lyon,France 3.1 Introduction:finite element analyses of composite forming, why and where? 46 3.2 The multiscale nature of composite materials and different approaches for composite forming simulations 48 3.3 The continuous approach for composite forming process analysis 50 3.4 Discrete or mesoscopic approach 57 3.5 Semi-discrete approach 59 3.6 Multi-ply forming and re-consolidation simulations 70 3.7 Conclusions 75 3.8 References 75 4 Virtual testing for material formability 80 Sunysijqnd S V LOMOV,Katholieke Universiteit Leuven,Belgium 4.1 Introduction 80 4.2 Mechanical model of the internal geometry of the relaxed state 82 wos' of a woven fabric 4.3 Model of compression of woven fabric 84 4.4 Model of uniaxial and biaxial tension of woven fabric 89 'ssaudmau'peaypoow/: 4.5 Model of shear of woven fabric 93 4.6 Parametric description of fabric behaviour under simultaneous shear and tension 96 02. 到 4.7 Conclusions:creating input data for forming simulations 111 4.8 References 112 5 Optimization of composites forming 117 W-R YU,Seoul National University,Korea 5.1 Introduction 117 5.2 General aspects of optimization 118 5.3 Optimization of composite forming 126 5.4 Conclusions 142 5.5 References 142 6 Simulation of compression moulding to form composites 144 E SCHMA CHTEN BERG,Universitat Erlangen-Nurnberg, Germany and K SK RODOLIES,Institut fur Kunststoffverarbeitung, Germany 6.1 Introduction 144 6.2 Theoretical description of the simulation 1453 Finite element analysis of composite forming 46 P BO I S S E , INSA de Lyon, France 3.1 Introduction: finite element analyses of composite forming, why and where? 46 3.2 The multiscale nature of composite materials and different approaches for composite forming simulations 48 3.3 The continuous approach for composite forming process analysis 50 3.4 Discrete or mesoscopic approach 57 3.5 Semi-discrete approach 59 3.6 Multi-ply forming and re-consolidation simulations 70 3.7 Conclusions 75 3.8 References 75 4 Virtual testing for material formability 80 S V LO M O V , Katholieke Universiteit Leuven, Belgium 4.1 Introduction 80 4.2 Mechanical model of the internal geometry of the relaxed state of a woven fabric 82 4.3 Model of compression of woven fabric 84 4.4 Model of uniaxial and biaxial tension of woven fabric 89 4.5 Model of shear of woven fabric 93 4.6 Parametric description of fabric behaviour under simultaneous shear and tension 96 4.7 Conclusions: creating input data for forming simulations 111 4.8 References 112 5 Optimization of composites forming 117 W-R YU , Seoul National University, Korea 5.1 Introduction 117 5.2 General aspects of optimization 118 5.3 Optimization of composite forming 126 5.4 Conclusions 142 5.5 References 142 6 Simulation of compression moulding to form composites 144 E SC H M A C H T E N B E R G , UniversitaÈt Erlangen-NuÈrnberg, Germany and K SK R O D O L I E S , Institut fuÈr Kunststoffverarbeitung, Germany 6.1 Introduction 144 6.2 Theoretical description of the simulation 145 vi Contents Copyrighted Material downloaded from Woodhead Publishing Online Delivered by http://woodhead.metapress.com Hong Kong Polytechnic University (714-57-975) Hong Kong Polytechnic University (714-57-975) Saturday, January 22, 2011 6:57:44 PM IP Address: 158.132.122.4