正在加载图片...

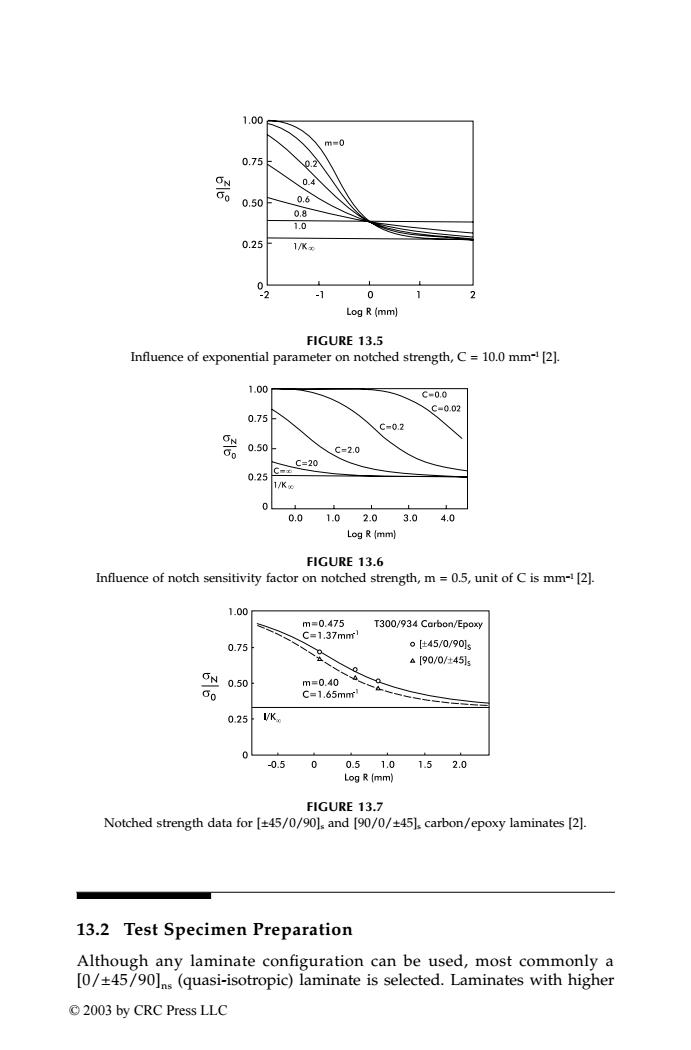

1.00 m=0 0.75 y 04 0.50 0.6 0.8 1.0 0.25 1/K -2 0 Log R(mm) FIGURE 13.5 Influence of exponential parameter on notched strength,C=10.0 mm-[2]. 1.00 C0.0 C-0.02 0.75 C-0.2 ON 0.50 C=2.0 C=20 0.25 1/K 0 0.01.02.03.04.0 Log R (mm) FIGURE 13.6 Influence of notch sensitivity factor on notched strength,m =0.5,unit of C is mm-1[2]. 1.00 m=0.475 T300/934 Carbon/Epoxy C=1.37mm 0.75 。±45/0/901s a[90/0/±45s N0.50 m=0.40 00 C=1.65mm 0.25 VK. 0 -0.5 0 0.51.0 1.52.0 Log R (mm) FIGURE 13.7 Notched strength data for [+45/0/90]s and [90/0/+45].carbon/epoxy laminates [2]. 13.2 Test Specimen Preparation Although any laminate configuration can be used,most commonly a [0/+45/90]s(quasi-isotropic)laminate is selected.Laminates with higher ©2003 by CRC Press LLC13.2 Test Specimen Preparation Although any laminate configuration can be used, most commonly a [0/±45/90]ns (quasi-isotropic) laminate is selected. Laminates with higher FIGURE 13.5 Influence of exponential parameter on notched strength, C = 10.0 mm–1 [2]. FIGURE 13.6 Influence of notch sensitivity factor on notched strength, m = 0.5, unit of C is mm–1 [2]. FIGURE 13.7 Notched strength data for [±45/0/90]s and [90/0/±45]s carbon/epoxy laminates [2]. TX001_ch13_Frame Page 174 Saturday, September 21, 2002 5:07 AM © 2003 by CRC Press LLC